Abubuwan Concan Kankare Don Magance Launin oldarfe Na Mutuwar 'Yan Wasa

1 Dalilai don mannewa simintin simintin

Haɗarin haɗewa da lahani na ƙyalli zuwa simintin gyare -gyare sune: lokacin da simintin mutuƙar ya makale a kan ƙirar, shimfidar wuri mai kauri ce, wacce ke shafar kaurin bayyanar; matsanancin simintin farfajiya yana ɓacewa, ba shi da nama, iri, da fasa, kuma yana iya sa simintin ya zube, wanda hakan ke haifar da ƙulle -ƙulle. Akwai abubuwan mamaki da yawa na mannewa da mutuƙar mutuƙar fata, kuma ainihin dalilan da yasa ake liƙawa sune kamar haka.

1.1 Kawancen mutuƙar siminti da baƙin ƙarfe

Mafi girman alaƙar da ke tsakanin mutuƙar simintin ƙarfe da mutuƙar ƙarfe, mafi sauƙin shine narke da haɗe da juna. Bayan da mutu-simintin gami ne bonded zuwa mold bango, za a yi mafi girma demolding juriya, da simintin za a strained lokacin demolding. A gani a hankali cewa akwai alamomin zane kamar shimfidar wuri, ɓarna ko ƙarancin kayan aiki a ɓangaren abin da aka makala na simintin (lura: za a rarrabe daga ajiyar carbon), kuma za a tsage kuma a lalace a yanayin adhesion mai tsanani. A farfajiya na kwandon shara ana gani da ido ga abin da aka ƙera, kuma launi fari ne.

Bayan allura ko kwararar ruwa mai mutuƙar siminti yana yin tasiri ga bangon ƙirar ko gindin, zafin zafin bangon ƙirar ko ainihin yana ƙaruwa. A yanayin zafi mai zafi, ruwan gami da ƙarfe mai ƙyalli na bango mai ƙyalƙyali yana narkewa da walɗa tare don haifar da haɗewar juna. Mafi girman zafin ruwa na alloy, mafi girman saurin allura, mafi girman zazzabi mai ƙyalƙyali da ƙananan ƙarancin taurin, mafi girman alaƙar da ke tsakanin ruwan gami na aluminium da ƙarfe mai ƙyalƙyali, mafi kusantar zai narke da mannewa. Lokacin da mutu surface manne da mutu simintin gami ne demolded, rami surface da simintin surface ne matsi da tsage, wanda zai tsaga surface na simintin, da surface na simintin zai bayyana m mold iri.

Mafi girman saurin cikawar ruwa mai mutuƙar simintin ruwa a cikin mai gudu na ciki, mafi tsananin tasirin narkakken ƙarfe ya kwarara akan bangon ƙirar. Karfe mai narkar da kai tsaye yana yin tasiri ga gindin ko bango, kuma tasirin tasirin yana canzawa zuwa ƙarfin zafi. Ba wai yawan zafin jiki na ruwan gami zai tashi kawai ba, amma yanayin zafin jiki a ɓangaren da abin ya shafa shima zai tashi da yawa, wanda hakan yana ƙaruwa ƙwarai tsakanin ruwan aluminium da ƙarfe. Sabili da haka, ƙuƙwalwar ƙuƙwalwar ƙila za ta iya faruwa a ɓangaren mai gudu a cikin injin da ke ƙarƙashin tasirin saurin-sauri na ruwan gami. Idan ya bugi gefen tsararren sifar, ƙarfin fakitin simintin gyare -gyare a gefen madaidaicin ƙirar yana ƙaruwa.

Ƙarfin ƙirar bai isa ba, kuma za a matse murfin yayin murƙushewa kuma ya lalace ta hanyar mutuƙar simintin, ko kuma ƙirar ƙirar za ta lanƙwasa kuma ta lalace, ta hakan yana haɓaka juriya na ƙwanƙwasawa zuwa rushewar simintin.

Amfani mara kyau na kayan kwalliya, lokacin da zafin zafin jiki ya yi yawa, allurar mutuƙar siminti tana sauƙaƙe saman farfajiyar.

1.2 Ƙasa kusurwa

Mope demolding gangara ne ma kananan (ko babu demolding gangara, ko baya demolding gangara), gefen mold ne m (yashewa, murkushe, lahani, da dai sauransu), surface ne m, da dai sauransu, da simintin da aka hana a hanyar rushewa. Fushin simintin yana ɓarna da ƙyallen lokacin da aka rushe simintin, kuma saman simintin yana nuna alamun layin layi tare da hanyar buɗe murfin, wato, tabo a farkon zurfin rami na simintin yana da faɗi kuma mai zurfi, yayin da tabo a ƙarshen ƙirar a hankali ya zama ƙarami ko ma ɓace. Cire dukkan fuska.

- (1) Tsarin ƙirar ƙirar da ƙira ba daidai ba ne, kuma gangaren dusar ƙanƙara na rami mai ƙyalli ko babban abin da ke kafa ƙasa ya yi ƙanƙanta ko yana da gangara mai juyi, wanda ke sa juriya ga siminti don ƙima sosai. Ga ɓangarorin da ba sa buƙatar ƙin jujjuyawar simintin gyare -gyare, zai fi kyau a bar izinin injin don yin simintin don yin ƙuƙwalwar taɓarɓarewa, sannan a bar sassan ba tare da ƙin jujjuyawar simintin gyaran ba daga baya.

- (2) Naƙasasshe naƙasasshe a kan ƙirar ƙirar ko bango mai ƙyalli da ɓarna a gefen ramin zai shafi rushewar simintin, kuma tarkace a saman farfajiya ko fasa ƙwanƙwasa zai kuma shafar rushewar simintin. .

Fuskar da aka ƙera na ƙirar tana da ƙarfi sosai, ko tana da alamun sarrafawa da ƙerawa, ba ta da isasshen santsi, ko layin sarrafawa da goge -goge ba su dace da alƙawarin da ke rushewa ba, ko ƙyalli a cikin shugabanci na rushewa ba shi da kyau, irin waɗannan munanan fuskoki za su ƙaru saboda Rashin juriya yana hana rushewar simintin, yana haifar da farfaɗuwar abin da aka samu na gogewa ko gogewa. Irin waɗannan alamomin karce su ne ramuka masu layi -layi a cikin ragargajewa, ramukan ba su da ƙasa da 0.1 mm, kuma mafi zurfin kusan 0.3 mm.

1.3 Matsanancin simintin gyare -gyaren zuwa ƙirar

Gaba ɗaya ko ƙuntatawa na simintin gyare -gyaren yana da ƙarfin matsawa a kan ƙirar, ko rarraba ƙarfin matsawa ba daidai ba ne kuma ba shi da ma'ana. A wannan lokacin, simintin gyare -gyaren zai gurɓata, ya fashe, ko ya karye saboda mannewar ƙirar, har ma da simintin zai manne da madaidaicin ƙirar. Ko kuma wataƙila akwai abin mamaki wanda simintin ya manne a saman sifa mai motsi kuma ba zai iya fitowa ba.

- (1) Gabaɗaya ko sashi mai ƙarfi na ɗaukar simintin gyare -gyaren zuwa madaidaicin ƙirar ya fi ƙarfin ɗaukar kaya zuwa ƙirar mai motsi, kuma simintin zai kasance makale lokacin da aka buɗe murfin.

- (2) Lokacin rushewa, idan ƙarfin ƙarfafa kowane sashi na simintin akan ƙa'idodin motsi da tsayayyen ba daidaituwa ba ne, za a karkatar da simintin, karkatar da shi, lokacin da aka fitar da shi, da ɓangaren simintin da za a shafi babban ƙarfi mai ƙarfi akan madaidaiciyar ƙirar. Yana iya tsayawa kan madaidaicin mold.

- (3) Idan zafin zafin da aka tsayar da shi ya yi ƙasa kaɗan ko zafin zafin da ke motsawa ya yi yawa, ƙarfin shiryawa na madaidaicin ƙirar zai zama mafi girma fiye da na motsi lokacin da simintin ya ragu.

- (4) Haɗin wakilin sakin ƙirar ya yi ƙasa kaɗan, aikin sakin wakilin sakin ba shi da kyau, wakilin sakin da aka fesa akan madaidaicin ƙirar ba a wurin ba, kuma adadin wakilin sakin bai isa ba, wanda zai shafi aikin sakin simintin gyare -gyare. Idan an fesa fenti da yawa a kan madaidaiciyar ƙirar a lokacin ƙirar mai zafi, zafin zafin da aka gyara yana da wahalar haɓaka cikin sauri. Bayan simintin gyare -gyare ya yi sanyi da raguwa, ƙarfin ƙarfafa a kan madaidaicin ƙirar ƙirar zai ƙaru fiye da mola mai motsi.

- (5) Hakanan akwai wani sabon abu mai ƙyalli mai ƙyalli: a farkon lokacin samar da mutuƙar simintin, wato lokacin da aka yiwa allura mai zafi a cikin ƙaramin saurin gudu, ruwan ruwan da ke ɗauke da baƙin ƙarfe zai mutu da sauri saboda ƙananan zafin jiki, wanda ke haifar da cika Ƙararren ƙarfe da ke cikin ramin bai cika cika ba, ƙarfin simintin da aka ƙera ya yi ƙasa kaɗan, kuma haɗin tsakanin sassa daban -daban na simintin yana da rauni sosai. Lokacin da aka rushe simintin gyare -gyare, ɓangaren da ya fi ƙarfin ƙarfafawa zai karye cikin sauƙi tare da wasu sassa. Ware da makale a cikin mold. Musamman, babu pin fil na ejector a gefen madaidaicin ƙirar don fitar da simintin gyare -gyare, don haka ya fi sauƙi a manne da madaidaicin ƙirar.

Dangane da abin da ke mannewa wanda ke faruwa a kowane lokaci yayin jifa, yakamata a bincika dalilan faruwar hakan dalla-dalla. Misali, idan simintin ya manne da madaidaicin sifa yayin mutuƙar simintin gyare -gyare, ya zama dole a bincika dalilin matsanancin ƙarfin ƙarfafa simintin akan madaidaicin ƙirar; duba bayyanar madaidaiciyar gefen simintin simintin gyare -gyare, bi umarnin murkushewa, kuma akwai alamun mutuƙar a saman simintin. Lokacin da ƙyalli mai ƙyalli ya yi ƙyalli ko ƙyalli, za a sami babban juriya na rushewa, wanda zai sa ɓangaren simintin ko duk simintin ba ya fitowa a cikin rami, kuma simintin zai ci gaba da makale kuma yana haifar da liƙa; a lokuta masu tsanani, ba kawai simintin zai tsage ba kuma ya lalace Al'amarin iri, fasa, da karaya na iya faruwa a cikin gindin da ramin sifa. Abubuwan da ke jingina na simintin mutuƙar sun fi yawa a cikin gami na aluminium. Matakan takamaiman don warware lalatattun lahani na simintin gyare -gyare sune kamar haka.

2 Matakan don hana simintin gyare -gyare zuwa madaidaicin ƙirar

2.1 Matakan don hana simintin gyare -gyare daga tsayayyen kyawon tsayuwa a cikin kyawon tsayuwa

A cikin ƙirar gwaji na sabon ƙirar da aka ƙera, ko lokacin da ƙirar mutuƙar ta fara ƙyalli mai zafi, abin da ke faruwa na mutuƙar simintin sau da yawa yana faruwa. Lokacin aiwatar da aikin mutu-simintin al'ada ne, babban dalilin jingina simintin ba shine tsarin mutuƙar simintin ba, amma yakamata ya zama matsalar ƙirar tsarin simintin, ƙirar ƙirar ko ƙerawa. Kodayake ana iya gyara tsarin mutuƙar simintin gyare-gyare da fesawa, tasirin maganin gabaɗaya ne kuma ba mai karko ba, kuma sabon abu na jingina zai ci gaba da faruwa.

Idan simintin gyare-gyare yana da saurin tsayawa kan madaidaicin ƙirar, yakamata a yi zafin zafin sosai kafin a mutu-simintin, kuma yakamata a rufe murfin murfin tare da manne mai ƙyalli da iska mai matsawa kafin fara allura mai saurin gudu. Ku busa a ko'ina, yi amfani da sau ɗaya don kowane ƙirar da ta mutu, gwada gwada simintin game da kyawon tsayuwa guda 20, idan har yanzu ƙirar tana da ƙarfi, yana nufin cewa ƙirar tana da matsala kuma tana buƙatar gyara.

Domin simintin gyare -gyaren da aka ƙera, gaskiya ne cewa ƙarfin ƙwanƙwasa simintin zuwa madaidaicin ƙirar ya fi ƙarfin ƙwanƙwasawa zuwa ƙirar mai motsi. Wajibi ne a ba da damar sanya simintin gyare -gyare a gefen madaurin da aka gyara don fitar da simintin gyare -gyare, da kuma ba da damar saman simintin a gefen madaurin. Bar alamomin ejector, ko sanya alamun cirewar mai sauƙin cirewa. Ta wannan hanyar, lokacin ƙera ƙirar, yakamata a tsara injin fitar da simintin a gefen madaidaiciyar ƙirar.

Kula da lissafin ƙarfin shiryawa na motsi da tsayayyen kyawon tsayuwa. Don simintin gyare -gyare wanda ƙarfin kwandon da aka yi da shi ya fi ƙarfin ɗaukar nauyin motsi mai motsi, ko don simintin gyare -gyare tare da ƙarfin kwandon madaidaicin ƙirar da motsi mai kama da na ƙaƙƙarfan motsi, yana yiwuwa a manne The tsayayyen mold na iya mannewa da simintin gyare -gyaren motsi. Lokacin ƙera simintin gyare -gyare ko ƙirar, ya zama dole a canza tsarin simintin gyare -gyare ko ƙirar, kusurwar daftarin, ƙyallen farfajiya, da dai sauransu, kuma a yi ƙoƙarin yin ƙarfin simintin ƙarfin motsi mai ƙarfi fiye da Ƙarfafa ƙarfi na tsayayyen mold.

Don simintin gyare -gyare tare da babban fakitin ƙarfi a gefe ɗaya na madaidaiciyar ƙirar, lokacin zayyana sabon ƙirar, yakamata a zaɓi farfajiyar da za ta yiwu a gefen da ke nuna son kai ga madaidaicin ƙirar, kuma ya kamata a sanya simintin a rami mai motsi mai motsi kamar yadda zai yiwu don haɓaka haɗin haɗin simintin gyare -gyare. Ƙarfafa ƙarfi na motsi mai motsi. Don rage ƙarfin ƙara ƙarfi akan madaidaiciyar ƙirar, ya zama dole a sake ƙayyade gangaren murƙushewar madaidaiciyar ƙirar tare da mai zanen simintin gyare-gyare, kuma yakamata a ƙara ƙarar murfin madaidaicin gwargwadon iko; ba da kulawa ta musamman don gyara ko ƙara simintin gyare -gyare a gefen madaidaicin sifa. Gangarɓarɓarewar ɓangaren ɓangaren da ke ɓarna da ƙirar da ke mannewa da ƙyallen. A lokaci guda, yadda ya dace rage raguwar gangaren juzu'i mai motsi; ba da kulawa ta musamman don gyara ko rage gangaren rushewar murfin motsi kusa da fil ɗin ejector. Yi ƙoƙarin saita ainihin akan ƙirar mai motsi, ko ƙara tsawon gindin a gefe ɗaya na mola mai motsi.

Wajibi ne a hana madaidaiciyar ƙera daga samar da ƙananan abubuwa ko maɗaukaki waɗanda ke shafar rushewar yayin ƙerawa da gogewa; bayan gwajin ƙirar ko yayin aiwatar da mutuƙar simintin, ya zama dole a gyara ɓarna na tsayayyen rami daga murƙushewa da ƙwanƙwasawa; yi amfani da goge goge ko sinadarai don kawar da gami Idan ba a cire alamar manne akan farfajiyar madaidaiciyar madaidaiciya ba kuma ba a cire masu haɗe -haɗe akan ƙirar a cikin lokaci ba, abin da ke makalewa zai zama mai tsanani bayan dogon lokaci; mafi kyau goge m surface na gefen bango na gyarawa mold rami. Amma bayan da aka goge madaidaicin madaurin a cikin madubi, ba zai dace da manne fenti ba. Lokacin da aka buɗe ƙirar, za a sami ramuka mai tsauri tsakanin simintin gyare -gyare da ƙirar, wanda ke haɓaka juriya na rushewa, don haka ba za a iya goge ƙasan madaidaicin rami mai zurfi a cikin saman madubi ba. . Don ƙirar da aka ƙera, yakamata a yi gogewa da kyau don hana lalacewar nitrided Layer akan farfajiya, kuma hana ƙarin gogewa, gwargwadon ƙirar za ta tsaya.

Gyara mai gudu mai ƙyalƙyali, daidai yadda yakamata ya canza matsayin, girman da cika shugabanci mai gudana don kawar ko rage gurɓataccen lahani da ke haifar da tasirin mai gudu akan madaidaicin ƙirar. Misali:

- HanYa canza madaidaicin juzu'i na zubin aluminium don rage tasirin tashin hankali na ƙarfe da aka ƙera akan madaidaicin rami. Kuna iya canza tasirin kai tsaye na ƙarfe mai narkewa don fuskantar ainihin ko bango ba da daɗewa ba;

- RopriYa dace da haɓaka sashin giciye na mai gudu na ciki. Domin rage yawan kuzarin ƙarfe mai narkarwa a cikin mai gudu na ciki;

- ③Ya canza matsayin mai gudu na ciki, sanya mai gudu na ciki a cikin faffada da kauri na simintin gyare -gyare, kuma ku guji tasiri kan bangon gefen madaidaicin sifa;

- RyKa yi ƙoƙarin ɗaukar abincin a ƙarƙashin rami mai zurfi na Hanyar simintin;

- DoYa dace da mai gudu a buɗe, bakin ƙarar mai gudu yana fuskantar rami don faɗaɗa yankin allura;

- ⑥Domin ɓangaren tasiri ko jigon mai gudu, ana iya amfani da injin murfin sandar tungsten carbide don amfani da wutar lantarki zuwa saman ƙirar.

Hanyar ƙarfe mai walƙiya ta feshe murfin microparticle tungsten carbide, barbashi na tungsten na ƙarfe da ƙarfe na tushe ba za su faɗi ba, wanda zai iya inganta haɓakar haɓakar shimfidar ƙirar, kamar saka murfin 2 zuwa 4 micron mai kauri akan farfajiya na mold-simintin mold, da taurinsa Zai iya isa HV4 000 ~ 4 500, kuma zafin aiki na iya kaiwa 800 ℃.

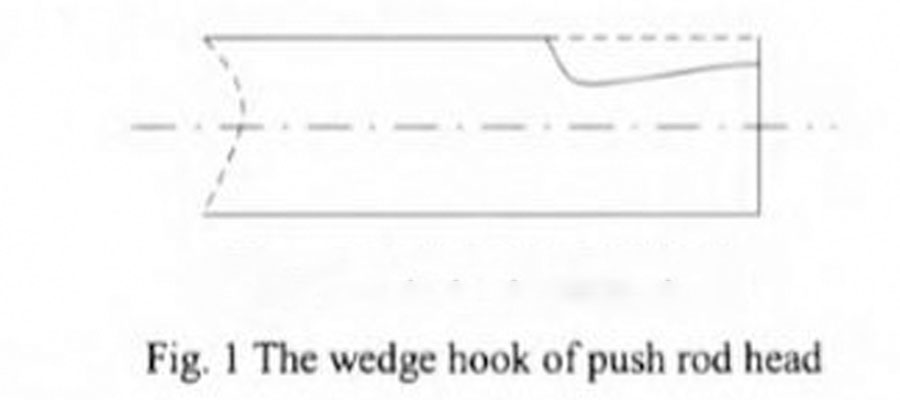

Domin jan simintin zuwa gefen madogarar da za a iya motsawa, ana iya gyara ƙugiyar ƙugiya mai siffa mai siffa daga kan sandar ejector (tsayin ƙugiya shine 5-8 mm, kuma kaurin ɓangaren simintin shine 1-2 mm , duba Hoto na 1), don yadda ƙugiyar ƙugiyar ƙwallon ƙwallon da aka mutu ta ja. Domin ƙara ƙarfin ƙarfafa simintin gyare -gyaren a kan ƙirar da za a iya motsawa, za a iya ƙara ƙarar da keɓaɓɓun sassan sassan don ɓangarorin da ke buƙatar kammalawa a kan simintin gyare -gyare da kuma gefen ɓangarorin waɗanda ba sa shafar bayyanar. inganci, ta yadda za a ƙara tasirin simintin gyare -gyare a kan ƙara ƙarfin ƙarfin motsi mai motsi. More bayyane.

Don ƙara ƙarfin ƙarfin motsi mai motsi, ana iya amfani da sandunan tashin hankali yadda yakamata (duba hoto 2):

- TheA yanayin rashin tasiri kan simintin simintin gyare -gyare, ana iya yin ramuka da yawa a gefen farfajiyar da za a iya motsawa ko farfajiyar gindin, ko hakora da yawa da zurfin kusan 0.1 zuwa 0.2 mm za a iya ƙasa a cikin injin . . Amma kula da cewa yakamata a buɗe ƙugiyar ƙugiya a kusa da sandar ejector don hana ƙarfin fitarwa mara daidaituwa;

- Hen Lokacin buɗe murfin, idan kuna son amfani da mai gudu don jawo simintin zuwa gefen ƙirar mai motsi ta hanyar mai gudu na ciki, zaku iya gyara haƙarƙarin tashin hankali a gefen mai gudu a gefen ƙirar mai motsi, ko niƙa wasu zurfin zurfin 0.2. Con 0.3 mm concave point don haɓaka ƙwanƙwasa mai gudu zuwa mai motsi mai motsi;

- Also Hakanan zaka iya saita fil ɗin ejector akan mai gudu kusa da mai gudu na ciki, taƙaitaccen fil ɗin ejector zuwa 5-8 mm ƙasa da ƙirar ƙirar, kuma gyara gefen inda fil ɗin ejector shine 3 mm a ƙasa da madaidaicin madaidaiciya zuwa faɗin 2 zuwa 3 mm, rami na shekara -shekara tare da zurfin 0.3 ~ 0.5 mm. Haƙarin haƙarƙarin shekara-shekara da aka kafa bayan mutuƙar simintin yana fitar da mai gudu, kuma mai gudu yana jan simintin zuwa gefen mabuɗin motsi ta cikin mai gudu na ciki. Sakamakon mafi kyau;

- FIdan yana faruwa ne saboda busawar ciyawar tana haifar da babban ƙarfi a kan kek ɗin da sprue, ana kawo simintin zuwa madaidaicin madaidaiciya, kuma ana iya gyara haƙarƙarin tensile a gefen mai gudu na motsi mai motsi da ɓarna. mazugi. Lokacin da aka buɗe ƙirar Jawo mai gudu da kek ɗin zuwa gefen kwatancen motsi tare da sandar tashin hankali;

- ⑤ Don simintin gyare -gyare tare da bango mai kauri, ko jakunkuna tare da ramuka na ciki waɗanda ke buƙatar kammalawa, bayan rage gangaren rushewar gindin motsi mai motsi, idan ba za a iya magance matsalar madaidaicin ƙirar ba, yana iya kasancewa a tsakiyar tsakiyar Tsawon An gyara tsintsiyar zobe mai fadin 2 zuwa 3 mm da zurfin 0.2 zuwa 0.5 mm don samar da hakarkarin tashin hankali, kuma haƙarƙarin haƙoran zobe yana jan simintin zuwa gefen ƙaya mai motsi. Lura cewa dole ne a sami fil 2 na ejector don fitar da simintin kusa da irin wannan don hana simintin daga nakasa.

Don simintin gyare -gyare wanda ƙarfin kwandonsa a gefen madaidaicin madaidaiciya ya fi ƙarfin tattarawa a gefen ƙirar mai motsi, don yin simintin gyare -gyare daga madaidaicin madaidaicin, farantin ejector, sandar ejector da sandar sake saitawa an tsara su don fitar da simintin kamar m mould. Yana yiwuwa a ƙara silinda mai ko maɓuɓɓugar ruwa a gefe ɗaya na madaidaicin ƙirar don tura farantin saman da sandar ejector akan madaidaiciyar ƙirar don fitar da simintin yayin buɗe murfin. Akwai marmaro a bayan farantin ejector. Lokacin da aka buɗe ƙirar, ana fitar da madaidaicin ƙirar ƙirar daga farfajiya. Lokacin da aka rufe ƙirar, ana amfani da farfajiya mai jujjuyawar motsi don tura sandunan sake saiti huɗu don tura farantin turawa mai ƙyalƙyali da mai siyarwa don sake saitawa.

Domin amfani da sandar ejector don fitar da simintin gyare-gyare daga madaidaiciyar ƙirar, sandar ƙugiya, toshewar tasiri da injin rolle mai kama da kwalin rabuwa na farantin sassa biyu (duba Figure 5, simintin, sandar ejector kuma ba a nuna sandar sake saitawa a cikin adadi ba), Dogaro kan aikin buɗe ƙirar don fitar da farantin turawa mai siyar da faranti don fitar da simintin gyare -gyare daga madaidaicin ƙirar. Tsarin shine kamar haka: Tsara tsarin fitarwa na fil na ejector don fitar da simintin don ƙirar da aka bayar, bari farantin ejector 5 na madaidaicin ƙirar ya shimfiɗa daga madaidaicin ƙirar ƙirar 6, kuma saita ƙugiyoyi huɗu (ko biyu) akan kwandon da za a iya motsawa 1. Hannun ƙugiyoyi huɗu (ko biyu) 4 suna miƙawa zuwa gefen madaidaicin ƙirar 6 lokacin da aka rufe sifar. Sandar ƙugiya 4, toshewar tasiri 7, bazara 3, da injin rolle 8 ana amfani da su don yin sandunan ƙugiya huɗu 4 da madaidaicin ƙirar Babban farantin turawa na ƙirar an haɗa shi da ƙugiya. Lokacin da aka buɗe ƙirar, ƙirar da ke motsi tana jan sandar 4 tana ƙulla madaidaicin ƙirar mai fitar da ruwa 5, kuma madaidaicin ƙirar yana tura mai fitar da 5 don matsar da sandar ejector don fitar da simintin daga madaidaiciyar ƙirar. A wannan lokacin, simintin gyare -gyaren da motsi mai motsi yana tafiya daidai da juna. Bayan motsi zuwa wani bugun jini, yi amfani da toshe mai tasiri, abin nadi, da injin bazara don kawar da ƙugiyoyin sandunan ƙugiyoyi huɗu daga madaidaicin ƙirar ƙirar turawa, madaidaiciyar ƙirar ƙirar turawa ta dakatar da motsi, kuma shimfidar ɓarna mai motsi. Hakanan ana amfani dashi lokacin rufe murfin. Tura sandunan sake saiti huɗu da baya zuwa madaidaiciyar ƙirar ƙirar turawa don yin madaidaicin ƙirar ƙirar ta koma matsayinta.

2.2 Matakan don hana simintin gyare -gyare daga madaidaicin ƙirar dangane da aiwatar da simintin mutu'a

Fesa rufi a kan ƙirar, saurin tasirin tasirin kwararar ruwan gami, da zazzabi mai ƙyalƙyali shine manyan abubuwan da ke shafar jinginar simintin.

Bambanci, inganci, maida hankali, matsayin fesawa, lokacin fesawa da adadin wakilin sakin mold yana shafar yanayin jingina na simintin Ⅲ. Yi amfani da adadin wakilin da aka fesa don daidaita tasirin sakin simintin a ɓangarorin biyu na motsi da tsayayyen kyawon tsayuwa. Domin hana simintin daga manne wa madaidaiciyar sifa, ana iya rage lokacin da adadin wakilin sakin da aka fesa akan ƙirar mai motsi. Fentin da aka fesa a kan kwandon da za a iya motsawa ya kamata ya zama siriri da daidaituwa, amma kada a rasa fenti. Ƙara adadin wakilin sakin da aka fesa akan madaidaiciyar ƙirar don rage zafin zafin farfajiyar ƙirar, musamman don farfaɗɗiyar ƙirar da aka ƙera da farfajiya tare da alamun zane, ƙara adadin fesawa. Lokacin da babu madaidaicin matsayi a gefen madaidaicin mutuƙar, ko babu alamar mutuƙar, kula da yadda yakamata ƙara yawan abin da aka fesa.

A farfajiyar ƙirar tare da alamomin zane, yi amfani da manti mai ƙyalli mai ƙyalli kafin a fesa fenti bayan mutuƙar simintin, don a sa sinadarin mai jingina ya lalace zuwa saman ƙirar a yanayin zafi mai zafi. An samu samuwar ruwa tsakanin ruwan gami da farfajiyar ƙirar Layer mai kauri mai kauri zai iya taka rawa mafi kyau a rushewa.

Daidaita daidai da sarrafa zafin jiki. Wajibi ne a bincika danniya na matse simintin gyare -gyare da kuma manne manne, bambancin zafin jiki na ƙirar da ƙanƙantar da simintin gyare -gyare, da alaƙar da ke tsakanin ƙirar zafin da ƙwanƙwasawar allo da ƙwanƙwasa ƙirar. Idan akwai m mold iri a saman da simintin, kokarin amfani da ƙananan mold zazzabi yayin tabbatar da surface ingancin da simintin. Idan simintin da kansa yana da ƙarfi mai ƙarfi, yi ƙoƙarin yin amfani da yanayin zafin jiki mafi girma, wanda zai iya rage ƙanƙantar da simintin gyare -gyare yayin rushewa, wato lokacin da simintin bai kai babban ƙarfi ba, zai fara rushewa.

A dangance rage zafin jiki na motsi mai motsi da haɓaka ƙuntatawa na simintin gyare -gyare na iya haɓaka ƙarar simintin zuwa ƙirar mai motsi; in mun gwada da ƙara yawan zafin jiki na tsayayyen mold da rage ƙuntatawa na simintin gyare -gyare na iya rage matsi na simintin zuwa madaidaicin ƙirar. Ƙara yawan kwarara ruwa mai sanyaya ruwa na motsi mai motsi zai iya rage yawan zafin jiki na ƙirar motsi; rage ko rufe kwararar ruwan sanyaya na madaidaiciyar madaidaiciya na iya ƙara yawan zafin jiki na madaidaiciyar ƙirar. Gabaɗaya, don simintin ƙarfe na ƙarfe na aluminium, auna zafin zafin farfajiyar rami mai motsi a cikin dakika 1 zuwa 3 bayan buɗe murfin. Yanayin farfajiyar bai kamata ya wuce 300 ℃ ba, zai fi dacewa (240 ± 40) ℃; kuma kafin rufe ƙwanƙwasa bayan fesawa Auna yanayin zafin farfajiyar ramin da aka gyara a cikin sakan 1 zuwa 3, kuma bai kamata ya zama ƙasa da 140 ℃ ba.

Zazzabin da ke zubowa, kamar zafin jiki mai ƙyalƙyali, na iya canza raguwar simintin gyare -gyare da matsin lamba. Ƙara yawan zazzabi mai zuƙowa da rage lokacin buɗe buɗaɗɗen na iya rage ƙarfin shiryawa, amma zai haɓaka kusanci tsakanin ruwan gami da ƙarfe mai ƙyalli, kuma yana haifar da yiwuwar mannewa a cikin ɓangaren katanga mai kauri.

3 Matakan don hana simintin da ke mannewa da sifar motsi

3.1 Matakan da za su hana simintin jingina da kwarjinin motsi dangane da kyawon tsayuwa

Babban dalilin simintin da ke mannewa da madogarar motsi shine cewa simintin gyaran kafa yana da ƙarfin ƙarfafawa sosai akan ƙirar mai motsi, kuma ƙarfin fitar da sandar ejector bai isa ba. Idan karfin fitarwar bai yi yawa ba, ya zama dole a kara matsin lamba na hydraulic ko saurin fitar da silinda na fitar da injin mutu-simintin. Idan diamita na abin cirewa ya yi ƙanƙanta, ko kuma adadin fil ɗin ejector ya yi ƙanƙanta, ƙarfin abin cirewa ba shi da ƙarfi, kuma tsinken na iya lanƙwasa ko ya karye.

Idan ƙarfin simintin da ke mannewa da ƙugiyar motsi mai ƙanƙanta ne, nau'in yana da sauƙi lokacin da aka rushe simintin, ko kuma juriya da ke haifar da ƙanƙanin yanayin ƙanƙara, amma simintin ya lalace lokacin da aka fitar da shi, kuma Ya kamata a goge sashi mai ƙyalli, nitrided, ko ƙara Adadin wakilin da aka fesa ya rage juriya. . Idan karfin simintin da ke manne da moda mai motsi yana da girma, simintin gyare -gyare yana da rauni sosai lokacin da aka rushe simintin, saman simintin ya karye ko ya katse, ko kuma fitar da simintin ta hanyar mai cirewa, yakamata a ƙara kusurwar simintin da ya dace. Inganta ƙirar simintin gyare -gyare ko kyandirori, da kawar da tsarukan da ba su dace ba waɗanda ke haifar da simintin gyare -gyare da keɓewa kuma yana shafar raguwa.

Don hana ƙwanƙwasa ƙirar da ke haifar da ƙarfin fitar da simintin gyare-gyare, sandunan turawa guda huɗu na injin mutu-simintin da ke tura farantin fitar da ƙirar dole ne su kasance iri ɗaya a tsayi, kuma bambancin kada ya fi 0.20 mm ; Matsayin turawa da mashin ɗin ya kamata Matsayin sandar ejector na simintin ya zama daidaitacce kuma mai dacewa, kuma bai kamata ya karkace daga tsakiyar ramin ƙyallen ba, kuma bai kamata ya karkace daga tsakiyar silinda ejector na mutu-simintin ba. mashin.

Idan saitunan da ke jawowa da cirewa ba su daidaita ba, simintin gyare-gyaren ba za a matsa ba daidai ba kuma za a karkatar da shi. Idan tsawon sandan turawa na silinda na fitar da ruwa na injin mutuƙar siminti ba ɗaya ba ne, ƙarfin fitar da simintin ba daidai ba ne, ko kuma matsayin da aka tura ba daidai ba ne, za a karkatar da simintin yayin fitarwa. . Matakan haɓakawa sune: gyara tsarin ƙirar, daidaita madaidaicin injin jan hankali da matsayin sandar ejector, don haka ana fitar da ƙarfin simintin, kuma tabbatar da cewa an fitar da simintin a layi ɗaya kuma daidai; daidaita tsarin fitar da abubuwa, matsayi da yawa na sandar turawa na injin simintin mutu (mafi sauƙin amfani da sandunan turawa 4-6) don yin sandunan ejector da simintin gyare-gyaren kwandon daidai gwargwado; ƙara adadin sandunan fitar da kaya da kyau, ƙara diamita na sandunan ejector, da kuma shirya matsayin sandar ejector don tabbatar da daidaiton fitarwa.

Idan juriya na nakasa na sassan lebur da simintin gyare-gyare na bango bai isa ba, yakamata a ƙara lamba da diamita na fil ɗin ejector. Hakanan zaka iya ƙara ƙaramin maigida a matsayin mai cirewa don barin fil ɗin ejector ya huta akan ƙaramin shugaba na simintin. Babban yankin fitar da ƙarfi yana sa ƙarfin simintin gyaran.

Yi amfani da ƙarfe mai ƙyalƙyali mai inganci, don haka lokacin da zazzabi mai ƙyalli ya yi yawa, ƙirar mutuƙar jefa ba ta da sauƙin bi a saman. Tare da ƙarfe mai ƙyalƙyali mai ƙyalƙyali, ƙananan fasawa ba za su samar da wuri ba akan farfajiyar ƙirar, wanda kuma yana kawar da tushen haɗaɗɗen gami.

Lokacin da taurin taurin bai isa ba ko kuma mai rauni, ruwan gami yana da saurin kamuwa da ƙura. Wajibi ne a bincika ko ƙwanƙwasa ƙirar tana da ma'ana, haka nan don bincika tsarin kula da zafi don hana ɓarnawar ƙirar ƙarfe. Taurin modulu, abubuwan da aka shigar da kayan kwalliya da duk muryoyin da za su iya tsayayya da tasirin mai gudu na ciki shine HRc3 ~ 5 sama da taurin ƙirar ƙirar ƙirar. Lokacin da ƙirar ƙirar ta tabbatar da cewa babu matsala, kuma simintin gyare -gyaren simintin har yanzu yana da wahala a kawar, matakan jiyya kamar nitriding, KANI 7C, murfin tungsten, PVD nano titanium plating, da sauransu dole ne a yi amfani da su don inganta farfajiyar taurin mold.

Don saman ramin murfin, gabaɗaya ana goge shi da dutsen mai da sandpaper. Idan kuna amfani da kayan aikin huhu don goge ɓangaren da ke mannewa, dole ne ku mai da hankali kada ku lalata ƙirar, don kada ku lalata nitride Layer akan farfajiyar ƙirar, in ba haka ba mafi gogewa, mafi ƙanƙantar da ƙirar za ta kasance. Halin. Lokacin tsaftace ɓangaren da ba shi da rami mai ƙyalli mai ƙyalli ko ƙyallen ƙyallen, za ku iya amfani da spatula don cire kumburin, sannan ku goge da sauƙi tare da sandpaper. Kada ku fitar da ramukan, in ba haka ba zai haifar da ƙara tsanantawa. Yi hankali kada ku yi amfani da ƙwanƙolin don tsabtace ƙoshin da ke manne a cikin ramin sifa a kowane lokaci, don kada ku yi ƙyallen ramin sifar.

3.2 Matakan da za a bi don hana simintin daga mannewa zuwa ga motsi mai motsi dangane da tsarin simintin mutuwa

Rage saurin allurar saurin injin na mutu-simintin, ko ƙara yankin mai gudu a cikin injin don dacewa ya rage saurin cika mai gudu. Idan an ƙara yankin mai gudu na ciki ba tare da ƙara saurin cika mai gudu na ciki ba, za a iya gajarta lokacin cikawa, ana iya rage yawan zafin da ake samu ta hanyar tasirin mai gudu na ciki, da tasirin rage tasirin na mai gudu na ciki za a iya cimmawa.

Daidaita rage matsi na simintin gyare-gyare: Don sassaƙaƙƙen shinge da simintin gyare-gyare ba tare da buƙatun rami ba, zaku iya zaɓar ƙaramin matsin lamba, kamar 40-55MPa; janar simintin zaɓin 55-75 MPa; don sassan katanga mai kauri da simintin gyare-gyare tare da buƙatun rami, yi amfani da matsin lamba mafi girma, Kamar 75 ~ 100MPa; lokacin da dole ne a yi amfani da babban matsin lamba, ana iya zaɓar 100 ~ 140 MPa. A mafi girma da simintin matsa lamba, da mafi alh theri da inji Properties na simintin, kuma mafi girma da tightness na simintin ga mold. Idan ƙulle ƙura ya auku, ya zama dole a tabbatar da amfani da matsi na simintin da ya dace. Daidaita rage lokacin buɗe murfin (lokacin sanyaya ƙwanƙwasa) don a iya murƙushe simintin a cikin zafin jiki mafi girma kuma ƙarfin ƙwanƙwasawar ƙirar bai kai matsakaicin ƙima ba, wanda zai iya rage ƙarfin ƙwanƙwasa simintin zuwa ƙirar kuma rage da manne da mold. digiri.

Idan kusurwar rushewa ta simintin ta yi ƙanƙanta, mai yiyuwa ne ta sa simintin ya manne da sifa. Sabili da haka, ya zama dole a zaɓi kushin murƙushewa daidai gwargwadon kayan gami da girman girman simintin. Lokacin da kumburi ya faru, haɓaka madaidaicin kusurwa na iya kawar da sabon abin da ke haifar da girgizar ƙasa da raguwa. Idan tsarin simintin ba shi da ma'ana, zai haifar da raguwar kowane sashi na simintin gyare -gyare a lokacin ƙuntatawa da sanyaya, kuma juriya ga raguwa ba daidai ba ne. Idan zai yiwu kuma ya zama dole, inganta tsarin ƙirar simintin gyare -gyare don yin kaurin katanga mai kauri, kamar canzawa Don kaurin sashin, yi ƙoƙarin zayyana ɓangarorin masu kauri a matsayin tsattsauran ramuka ko haƙarƙarin haɗin haɗin gwiwa; kauce wa sassan canzawa tare da manyan kauri masu kauri; kawar da m shugabannin, lugs, da ƙarfafa hakarkarinsa. Ƙara fillet ɗin simintin gyare -gyare ko kushewar kusurwa a kusurwar concave na simintin gyare -gyare na iya hana liƙa.

A cikin kusancin mai gudu na ciki na kwandon da ɓangaren inda ruwan gami ya cika ramin tasirin, ɓangaren ƙirar tare da kaurin bango mai kauri a cikin simintin gyare -gyare, da kuma kusurwar da aka ƙera ta simintin, yana da sauƙin shafar ruwa mai rufi na dogon lokaci. Ana jingina sanduna da iri, don haka yakamata a samar da bututu na ruwa mai sanyaya don waɗannan ɓangarorin ƙirar don sanyaya ruwa. Don siriri mai sanyin gaske, ya kamata a ƙara matsin ruwan sanyaya. Waɗannan na iya rage zafin zafin jiki da hana ƙyalli.

Idan murfin simintin ƙarfe ya manne da ƙirar shimfiɗar a saman simintin, wasu ƙananan kumfa suna bayyana akan farfajiya. Don wannan sabon abu, ana goge farfajiyar tare da zane mai tsummoki da dutsen mai kuma ana sake maimaita murfin, wanda ba zai iya magance matsalar gaba ɗaya ba. Hanya mafi kyau don warware irin wannan liƙa shine yin peening harbi a saman murfin mai ɗorawa, ko yin farfajiyar ɓangaren abin da ke manne tare da faɗin 0.2 ~ 0.5 mm da zurfin 0.2 ~ 0. Tsarin saiti na 5 mm da tazara tsakanin 2 zuwa 5 mm na iya kawar da lahani na mannewa a saman simintin.

Ragewar mai gudu yana haifar da nakasa da juji. Ya kamata a kara tsawon mai gudanar da reshen don rage yankin mai gudanar da reshen; ya kamata a rage fadin mai gudu, a kara tsawon mai gudu, a rage mai gudu. Yawan tashoshi; ƙara sanyaya masu gudu na siyarwa ta hanyar ruwan sanyaya, don kawar da tasirin raguwar masu gudu a kan simintin gyare -gyare.

Ƙananan abun ciki na ƙarfe na baƙin ƙarfe na aluminium (kamar <0.6%), mafi girman kusanci tsakanin ruwan gami na aluminium da ƙarfe mai ƙyalƙyali, kuma mafi kusantar shine ya tsaya kan ƙirar. Daidai ƙara ƙarfe abun ciki na ruwa mai ruɓi na aluminium zai iya mafi kyawun rage adhesion na aluminium zuwa ƙirar; gabaɗaya ana buƙatar cewa abun cikin baƙin ƙarfe a cikin ruwa mai narkar da allurar aluminium ana sarrafa shi a 0.6% zuwa 0.95%. Wajibi ne don hana ƙyallen ƙyallen da ya haifar ta haɗuwa da ƙananan ƙarfe mai narkewa. Lokacin amfani da babban allo don daidaita abun da ke cikin sinadarai, ban da keɓaɓɓun ƙarfe kamar magnesium da zinc, ba za a iya ƙara ƙaramin ƙarfe a cikin ruwa na aluminium don hana rarrabuwar kawuna daga haifar da mannewa ba.

Mafi girman ƙanƙarar murɗaɗɗen murɗaɗɗen mutuƙar, ba wai kawai ya fi sauƙi a manne da ƙirar ba, har ma da mafi girman ƙarfin zafin zafin. Wasu gami suna da ƙima mafi girma; da fadi da ruwa da kuma m lokaci zafin jiki kewayon gami, mafi girma da shrinkage na gami. Dangane da tsarin sifa da rikitarwa na simintin, idan ƙirar da ke mannewa da nakasa da ke haifar da raguwa yana da wahalar kawarwa, yi la'akari da sauyawa zuwa wani allo tare da ƙanƙantar da jiki da ƙanƙantar da kai da kuma ƙarfin zafin zafin; ko daidaita abun da aka haɗa (kamar aluminium). Lokacin da abun cikin silicon a cikin allurar siliki ya ƙaru, ƙimar raguwar simintin ya zama ƙarami) don rage ƙuntatawa; ko don gyara allo, ƙara 0.15% zuwa 0.2% na titanium na ƙarfe da sauran masu gyara hatsi zuwa ruwan gami na aluminium don rage ƙaƙƙarfan Halin da ke raguwa.

Kammalallen 4

Akwai dalilai da yawa na mannewar simintin gyaran kafa, kuma matakan da za a bi don warware manne su ma sun bambanta. Labarin ya ba da shawarar matakan musamman don magance lalatattun lalatattun mutuƙar simintin. Yakamata mu lura da kuma bincika dalilan tsayawa, da ɗaukar matakan da aka yi niyya. Matakan da suka dace masu dacewa zasu iya magance matsalar ƙyallen ƙyallen.

Da fatan za a adana tushe da adireshin wannan labarin don sake bugawa: Abubuwan Concan Kankare Don Magance Launin oldarfe Na Mutuwar 'Yan Wasa

Minghe Gyare Company aka sadaukar domin tsirar da kuma samar da inganci da high yi Gyare sassa (karfe mutu simintin sassa Range yafi hada da Thin-Wall Mutu Wasa,Hot Chamber Mutu Wasa,Cold Chamber Mutu Wasa), Zagaye Sabis (Mutuwar 'Yan Wasa,CNC machining,Motsa Motsa, Jiyya na sama) .Adadin al'ada Aluminium ya mutu, magnesium ko Zamak / zinc mutu simintin gyare-gyare da sauran buƙatun simintin maraba don tuntube mu.

Karkashin kulawar ISO9001 da TS 16949, Ana aiwatar da dukkan matakai ta hanyar daruruwan injunan jefa simintin da suka mutu, injunan axis 5, da sauran kayan aiki, tun daga masu fashewa zuwa na’urar Ultra Sonic masu wanki.Minghe ba kawai tana da kayan aiki na zamani ba amma kuma tana da kwararru ƙungiyar ƙwararrun injiniyoyi, masu aiki da sufetoci don tabbatar da ƙirar abokin ciniki ta zama gaskiya.

Manufactureran kwangilar masana'antar mutu. Abubuwan haɓakawa sun haɗa da sassan sanyi na sassan mutuɗar aluminum daga 0.15 lbs. zuwa 6 lbs., saurin canje-canje da aka saita, da aikin inji. Sabis-ƙarin ayyuka sun haɗa da gogewa, faɗakarwa, lalatawa, fashewar harbi, zane, zane, rufi, haɗuwa, da kayan aiki. Abubuwan da aka yi aiki tare sun haɗa da allo irin su 360, 380, 383, da 413.

Zinc ya mutu don jefa ƙirar ƙira / sabis na injiniya tare. Custom manufacturer na daidaici tutiya mutu simintin gyaran kafa. Castananan 'yan simintin gyare-gyare, pressurean ƙwanƙwasa masu juzu'in juzu'in simintin gyare-gyaren juzu'ai, ƙera simintin gyare-gyare na al'ada, ɓangaren mutu da' yan wasa masu mutuwa masu zaman kansu da ƙofar da aka hatimce za a iya ƙera su. Za'a iya kerarrar 'yan simintin a tsayi da faɗi har zuwa 24 a ciki. A cikin +/- 0.0005 a cikin. Haƙuri.

ISO 9001: 2015 bokan masana'anta ta mutu magnesium, Abubuwan haɓaka sun haɗa da matsin lamba na magnesium mai matsi mai yawa har zuwa tan 200 mai ɗumi mai zafi & 3000 ton mai sanyi, ƙirar kayan aiki, gogewa, gyare-gyaren, inji, foda & zanen ruwa, cikakken QA tare da damar CMM , taro, marufi & isarwa.

ITAF16949 bokan. Servicearin Sabis ɗin Gyare Hadawa zuba jari,yashi,Kushin nauyi, Stauren ɓoye ɓoye,Siffar Centrifugal,Cast Vacuum,Dindindin Mould Gyare, .Hanyoyin iyawa sun hada da EDI, taimakon injiniya, ingantaccen samfuri da aiki na sakandare.

Fitar Masana'antu Abubuwan Nazarin sassa don: Motoci, Bikes, Jirgin sama, kayan kiɗa, Jirgin ruwa, Na'urorin hangen nesa, na'urori masu auna sigina, na'urori masu auna sigina, Na'urori, Kayan lantarki, ,unshi, Clocks, Inji, Injiniya, Kayan Kaya, Kayan Jiki, Jigs, Telecom, Haske, Kayan aikin likita, Na'urar daukar hoto, Robobi, Sassaka, kayan sauti, kayan wasanni, Kayan aiki, Kayan wasa da ƙari.

Me Zamu taimake ku yi gaba?

Je zuwa Shafin Farko Don Mutu Wasa China

→Sassan Kasuwanci-Gano abin da muka aikata.

→ Tallan kwankwasiyya Game da Ayyukan Gyare Mutuwa

By Minghe Mutu Wasa Wasa | Categories: Labarai masu Taimakawa |Material Tags: Gyare Aluminum, Zinc Gyare, Fitar Magnesium, Castan Wasanni, Bakin Karfe Cast, Fitar tagulla,Gyare Tagulla,Fitar Bidiyo,Tarihin Kamfanin,Aluminum Mutu Gyare | Comments Off