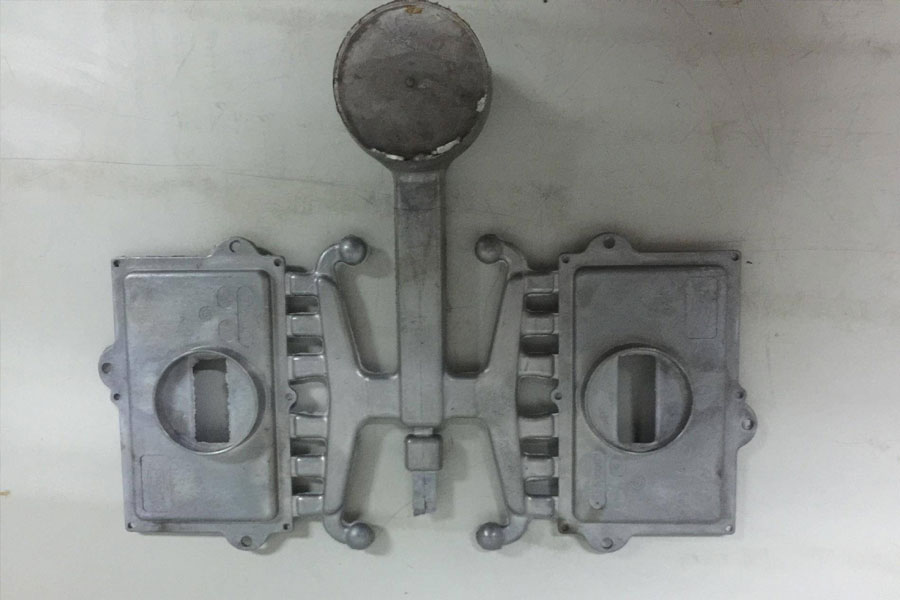

Tambayoyi 7 A Filin ƙera Mould

Menene babban abin da ke shafar sarrafa kayan?

Haɗin sinadarin ƙarfe yana da mahimmanci. A mafi girma gami abun da ke cikin karfe, mafi wuya shi ne aiwatar. Lokacin da abun cikin carbon ke ƙaruwa, aikin yanke ƙarfe yana raguwa.

Tsarin ƙarfe kuma yana da mahimmanci don aikin yanke ƙarfe. Tsarin daban -daban sun haɗa da: ƙirƙira, simintin, cirewa, birgima, da kera. Manufa da simintin gyare -gyare suna da shimfidar wurare masu wahala ga injin.

Hardness abu ne mai mahimmanci wanda ke shafar aikin yanke ƙarfe. Dokar gabaɗaya ita ce mafi ƙarfin ƙarfe, yana da wahala ga injin. Ana iya amfani da ƙarfe mai sauri (HSS) don sarrafa kayan tare da taurin har zuwa 330-400HB; ƙarfe mai sauri + rufin TiN na iya sarrafa kayan tare da taurin har zuwa 45HRC; kuma don kayan da ke da taurin 65-70HRC, dole ne ku yi amfani da carbide na ciminti, yumbu, cermets da cubic boron nitride (CBN).

Abubuwan da ba na ƙarfe ba gaba ɗaya suna da tasiri mara kyau akan rayuwar kayan aiki. Misali, Al2O3 (alumina), wanda shine yumbu mai tsabta, yana da ƙyama sosai.

Na ƙarshe shine damuwa na saura, wanda zai iya haifar da matsalolin aikin yanke ƙarfe. Sau da yawa ana ba da shawarar yin aikin taimako na danniya bayan m inji.

Menene halayen yankan baƙin ƙarfe?

Gabaɗaya magana, shine:

Mafi girman taurin da ƙarfin ƙarfe na ƙarfe, ƙananan aikin yanke ƙarfe, da ƙananan rayuwar da ake tsammanin daga ruwan wukake da masu yankewa. Yawancin nau'ikan ƙarfe na ƙarfe da aka yi amfani da su wajen ƙera ƙarfe gabaɗaya suna da aikin yanke ƙarfe mai kyau. Ayyukan yankan ƙarfe yana da alaƙa da tsari, kuma baƙin ƙarfe mai pearlitic mai wuya shima ya fi wahalar aiwatarwa. Flake graphite cast iron da malleable cast iron suna da kyawawan kaddarorin yankan, yayin da ductile cast iron yana da kyau.

Babban nau'in suturar da ake fuskanta lokacin da ake kera baƙin ƙarfe sune: abrasion, adhesion da diffusion wear. Abrasion galibi yana haifar da carbides, barbashi yashi da fatun fata. Haɗin haɗin gwiwa tare da gefen da aka gina yana faruwa a ƙananan zafin zafin jiki da saurin yankewa. Sashin ferrite na baƙin ƙarfe shine mafi sauƙi don haɗawa da ruwa, amma ana iya shawo kan wannan ta ƙara saurin yankan da zafin jiki.

A gefe guda, suturar watsawa yana dogaro da zafin jiki kuma yana faruwa a cikin saurin yankewa, musamman lokacin da ake amfani da maki ƙarfe mai ƙarfi. Waɗannan maki suna da babban juriya ga nakasa, wanda ke haifar da matsanancin yanayin zafi. Wannan suturar tana da alaƙa da mu'amala tsakanin baƙin ƙarfe da kayan aikin yankan, wanda ke sa wasu baƙin ƙarfe suna buƙatar a sarrafa su da yumɓu ko cubic boron nitride (CBN) a cikin manyan hanyoyin don samun ingantaccen kayan aiki da ingancin farfajiya.

Gabaɗaya, kayan aikin kayan aikin da ake buƙata don ƙera baƙin ƙarfe sune: babban taurin zafi da kwanciyar hankali na sunadarai, amma kuma yana da alaƙa da tsari, kayan aiki da yanayin yankewa; ana buƙatar yanke yanke don samun tauri, juriya gajiya da ƙarfi. Matsayin gamsuwa na yanke baƙin ƙarfe ya dogara ne akan yadda saɓin yankan ke tasowa: saurin ɓarna yana nufin fashewar ƙura da ƙura suna haifar da yanke yankewa da wuri, lalacewar kayan aiki, rashin kyawun farfajiya, waviness mai yawa, da dai sauransu. , daidaituwa, da kaifin yankan kaifi shine abin da gabaɗaya ke buƙatar ƙoƙari.

Menene manyan hanyoyin sarrafawa na yau da kullun a masana'antar kera?

Ya kamata a raba tsarin yankan zuwa aƙalla nau'ikan tsari 3:

M inji, m-karewa da ƙarewa, kuma wani lokacin har ma da kammalawa mafi yawa (galibi aikace-aikacen yankan sauri). An shirya injin daskararre don gamawa bayan aiwatar da ƙarshen kammalawa. A cikin kowane tsari, yakamata a yi ƙoƙarin barin gefe ɗaya da aka rarraba don tsari na gaba, wanda yake da matukar mahimmanci. Idan shugabanci da nauyin aikin kayan aikin da wuya ya canza cikin sauri, rayuwar kayan aikin na iya tsawaitawa kuma ana iya hasashe. Idan za ta yiwu, yakamata a aiwatar da aikin gamawa akan kayan aikin injin da aka keɓe. Wannan zai inganta daidaiton geometric da ingancin ƙirar a cikin gajeriyar ɓarna da lokacin taro.

Waɗanne irin kayan aiki yakamata a yi amfani da su a cikin waɗannan matakai daban -daban?

M machining tsari: zagaye ruwa milling abun yanka, ball karshen milling abun yanka da karshen milling abun yanka tare da babban hanci baka radius.

Semi-kammala tsari: zagin injin jujjuyawar ruwa (mai yankan raƙuman ruwa na ruwa tare da kewayon diamita na 10-25mm), mai yanke ƙwallo.

Tsarin kammalawa: mai yankan ruwa mai yanke ruwa, mai yankan ball.

Tsarin milling na saura: mai yankan ruwan injin ruwa mai zagaye, mai yankan ƙwallon ƙwallo, mai yanke milling a tsaye.

Yana da matukar mahimmanci a inganta tsarin yankewa ta hanyar zaɓar haɗuwar manyan kayan aiki na musamman, geometries da maki, kazalika da yanke sigogi da dabarun milling masu dacewa.

Don manyan kayan aikin da za a iya amfani da su, duba kundin adireshi C-1102: 1 don yin ƙere-ƙere

Shin akwai ɗayan mahimman abubuwan da ke cikin aiwatar da yanke?

Ofaya daga cikin mahimman maƙasudai a cikin tsarin yanke shine ƙirƙirar alƙawarin da aka rarraba na kayan aiki don kowane kayan aiki a cikin kowane tsari. Wannan yana nufin cewa dole ne a yi amfani da kayan aiki na diamita daban-daban (daga babba zuwa ƙarami), musamman a cikin ƙira da ayyukan gama-gari. Babban ma'auni a kowane lokaci yakamata ya kasance yana da kusanci da siffar ƙarshe na ƙirar a cikin kowane tsari.

Bayar da alawus na injin da aka rarraba daidai gwargwado ga kowane kayan aiki yana tabbatar da ɗimbin ɗimbin aiki da ingantaccen tsarin yankewa. Lokacin da ap/ae (zurfin axial na yanke/radial zurfin yanke) bai canza ba, ana iya kiyaye saurin yankan da ƙimar abinci koyaushe a babban matakin. Ta wannan hanyar, aikin injiniya da canje -canjen aikin aiki a kan yankewa ƙarami ne, don haka zafi da gajiya da aka samar su ma kaɗan ne, ta hakan yana haɓaka rayuwar kayan aiki. Idan hanyoyin da ke biyo baya wasu matakai ne na kammalawa na ƙarshe, musamman duk hanyoyin kammalawa, ana iya aiwatar da aikin mutum mara izini ko kuma wani ɓangare mara sarrafa mutum. Ba da izinin kayan aiki na yau da kullun shima shine babban ma'auni don aikace-aikacen yankan sauri.

Wani sakamako mai fa'ida na alƙawarin da ake amfani da shi akai-akai shine ƙaramin tasiri a kan raƙuman jagorar kayan aikin injin, dunƙule ƙwal da ƙuƙwalwar sanda.

Me yasa masu yankan shinge na ruwa na ruwa shine mafi kyawun zaɓi don kayan aikin juyawa?

Idan ana amfani da abin yanka injin kafada don ƙwanƙwasa ramin rami, za a cire babban adadin alaƙa da aka yanke a cikin injin na ƙarshe. Wannan zai canza ƙarfin yankan kuma ya sa kayan aikin su lanƙwasa. Sakamakon haka shine barin izinin sarrafa kayan aiki mara daidaituwa don ƙarewa, ta yadda zai shafi daidaiton geometric na mold. Idan kun yi amfani da mai yankan kafada mai faɗin kafada (tare da saka mai kusurwa uku) tare da raunin hanci, zai haifar da tasirin yankan rashin tabbas. Abubuwan da ke da kusurwa uku ko na lu'u -lu'u suma za su samar da manyan yankan radial, kuma saboda adadin abubuwan da ake sakawa 'yankan ƙaramin abu ne, ba su da ƙarancin kayan aikin tattalin arziƙi.

A gefe guda, za a iya yin juzu'in sakawa a cikin kayan daban -daban kuma ta kowane bangare. Idan an yi amfani da shi, sauyawa tsakanin hanyoyin kayan aiki na kusa yana da daɗi, kuma yana iya barin ƙarami da ƙarin kayan aiki na gama-gari. gefe. Ofaya daga cikin halaye na ruwan wukake shine kaurin kwakwalwan da suke samarwa yana canzawa. Wannan yana ba su damar amfani da ƙimar abinci mafi girma fiye da yawancin sauran abubuwan da aka saka.

An canza kusurwar shigarwa na zagaye saka daga kusan sifili (yankan rami mai zurfi) zuwa digiri 90, kuma aikin yanke yana da santsi sosai. A matsakaicin zurfin yanke, kusurwar shiga shine digiri 45. Lokacin yankewa tare da bango madaidaiciya tare da da'irar waje, kusurwar shiga shine digiri 90. Wannan kuma yana bayanin dalilin da yasa ƙarfin kayan aikin zagaye na ruwa babba-nauyin yankan yana ƙaruwa a hankali. Roughing da semi-roughing koyaushe yakamata su yi amfani da masu yanke shinge na ruwa, kamar CoroMill200 (duba kundin masana'antar kera C-1102: 1) a matsayin zaɓin farko. A cikin yankan 5-axis, shigarwar zagaye sun dace sosai, musamman tunda ba shi da ƙuntatawa.

Ta hanyar yin amfani da shirye -shirye masu kyau, zagaye na saka milling cutters na iya maye gurbin manyan injinan ƙwallo. An haɗa ruwan zagaye tare da ƙaramin gudu tare da ƙasa mai kyau, kusurwar rake mai kyau da geometry mai yanke haske, kuma ana iya amfani da shi don kammalawa da wasu matakai na ƙarewa.

Menene saurin yankewa (ve) kuma me yasa koyaushe yake da mahimmanci don ƙididdigar mahimmancin saurin yankewa mai ƙarfi akan ingantaccen diamita na babban yawan aiki.

Tun da abincin tebur ya dogara da saurin juyawa a wani saurin yankewa, idan ba a kirga saurin tasiri ba, za a lissafa abincin tebur ba daidai ba.

Idan ana amfani da diamita na kayan aiki (Dc) lokacin ƙididdige saurin yankewa, lokacin da zurfin yanke ba shi da zurfi, tasiri ko saurin yankewa ya yi ƙasa da ƙimar da aka lissafa. Irin su kayan aikin CoroMill200 na zagaye (musamman a cikin ƙaramin ƙaramin diamita), injin ƙwallon ƙwal, manyan injunan ƙaramin hancin hancin CoroMill390 da sauran kayan aikin (don waɗannan kayan aikin, don Allah koma zuwa Sandvik Coromant's mold manufacturer Samfurin C-1102: 1 ). Sakamakon haka, ƙimar abincin da aka lissafa shima ya yi ƙasa sosai, wanda ke rage yawan aiki sosai. Mafi mahimmanci, yanayin yanke kayan aiki ya yi ƙasa da ƙarfinsa da shawarar aikace -aikacen da aka ba da shawarar.

Da fatan za a adana tushe da adireshin wannan labarin don sake bugawa:Tambayoyi 7 A Filin ƙera Mould

Minghe Kamfanin 'Yan Wasa Masu Mutu aka sadaukar domin tsirar da samar da inganci da kuma high yi Gyare sassa (karfe mutu simintin sassa Range yafi hada da Thin-Wall Mutu Wasa,Hot Chamber Mutu Wasa,Cold Chamber Mutu Wasa), Zagaye Sabis (Mutuwar 'Yan Wasa,CNC machining,Motsa Motsa, Jiyya na sama) .Adadin al'ada Aluminium ya mutu, magnesium ko Zamak / zinc mutu simintin gyare-gyare da sauran buƙatun simintin maraba don tuntube mu.

Karkashin kulawar ISO9001 da TS 16949, Ana aiwatar da dukkan matakai ta hanyar daruruwan injunan jefa simintin da suka mutu, injunan axis 5, da sauran kayan aiki, tun daga masu fashewa zuwa na’urar Ultra Sonic masu wanki.Minghe ba kawai tana da kayan aiki na zamani ba amma kuma tana da kwararru ƙungiyar ƙwararrun injiniyoyi, masu aiki da sufetoci don tabbatar da ƙirar abokin ciniki ta zama gaskiya.

Manufactureran kwangilar masana'antar mutu. Abubuwan haɓakawa sun haɗa da sassan sanyi na sassan mutuɗar aluminum daga 0.15 lbs. zuwa 6 lbs., saurin canje-canje da aka saita, da aikin inji. Sabis-ƙarin ayyuka sun haɗa da gogewa, faɗakarwa, lalatawa, fashewar harbi, zane, zane, rufi, haɗuwa, da kayan aiki. Abubuwan da aka yi aiki tare sun haɗa da allo irin su 360, 380, 383, da 413.

Zinc ya mutu don jefa ƙirar ƙira / sabis na injiniya tare. Custom manufacturer na daidaici tutiya mutu simintin gyaran kafa. Castananan 'yan simintin gyare-gyare, pressurean ƙwanƙwasa masu juzu'in juzu'in simintin gyare-gyaren juzu'ai, ƙera simintin gyare-gyare na al'ada, ɓangaren mutu da' yan wasa masu mutuwa masu zaman kansu da ƙofar da aka hatimce za a iya ƙera su. Za'a iya kerarrar 'yan simintin a tsayi da faɗi har zuwa 24 a ciki. A cikin +/- 0.0005 a cikin. Haƙuri.

ISO 9001: 2015 bokan masana'anta ta mutu magnesium, Abubuwan haɓaka sun haɗa da matsin lamba na magnesium mai matsi mai yawa har zuwa tan 200 mai ɗumi mai zafi & 3000 ton mai sanyi, ƙirar kayan aiki, gogewa, gyare-gyaren, inji, foda & zanen ruwa, cikakken QA tare da damar CMM , taro, marufi & isarwa.

ITAF16949 bokan. Servicearin Sabis ɗin Gyare Hadawa zuba jari,yashi,Kushin nauyi, Stauren ɓoye ɓoye,Siffar Centrifugal,Cast Vacuum,Dindindin Mould Gyare, .Hanyoyin iyawa sun hada da EDI, taimakon injiniya, ingantaccen samfuri da aiki na sakandare.

Fitar Masana'antu Abubuwan Nazarin sassa don: Motoci, Bikes, Jirgin sama, kayan kiɗa, Jirgin ruwa, Na'urorin hangen nesa, na'urori masu auna sigina, na'urori masu auna sigina, Na'urori, Kayan lantarki, ,unshi, Clocks, Inji, Injiniya, Kayan Kaya, Kayan Jiki, Jigs, Telecom, Haske, Kayan aikin likita, Na'urar daukar hoto, Robobi, Sassaka, kayan sauti, kayan wasanni, Kayan aiki, Kayan wasa da ƙari.

Me Zamu taimake ku yi gaba?

Je zuwa Shafin Farko Don Mutu Wasa China

→Sassan Kasuwanci-Gano abin da muka aikata.

→ Tallan kwankwasiyya Game da Ayyukan Gyare Mutuwa

By Minghe Mutu Wasa Wasa | Categories: Labarai masu Taimakawa |Material Tags: Gyare Aluminum, Zinc Gyare, Fitar Magnesium, Castan Wasanni, Bakin Karfe Cast, Fitar tagulla,Gyare Tagulla,Fitar Bidiyo,Tarihin Kamfanin,Aluminum Mutu Gyare | Comments Off