hakowa

Menene Cnc Drilling Process & Drilling Machining & - Ayyukan hakowa

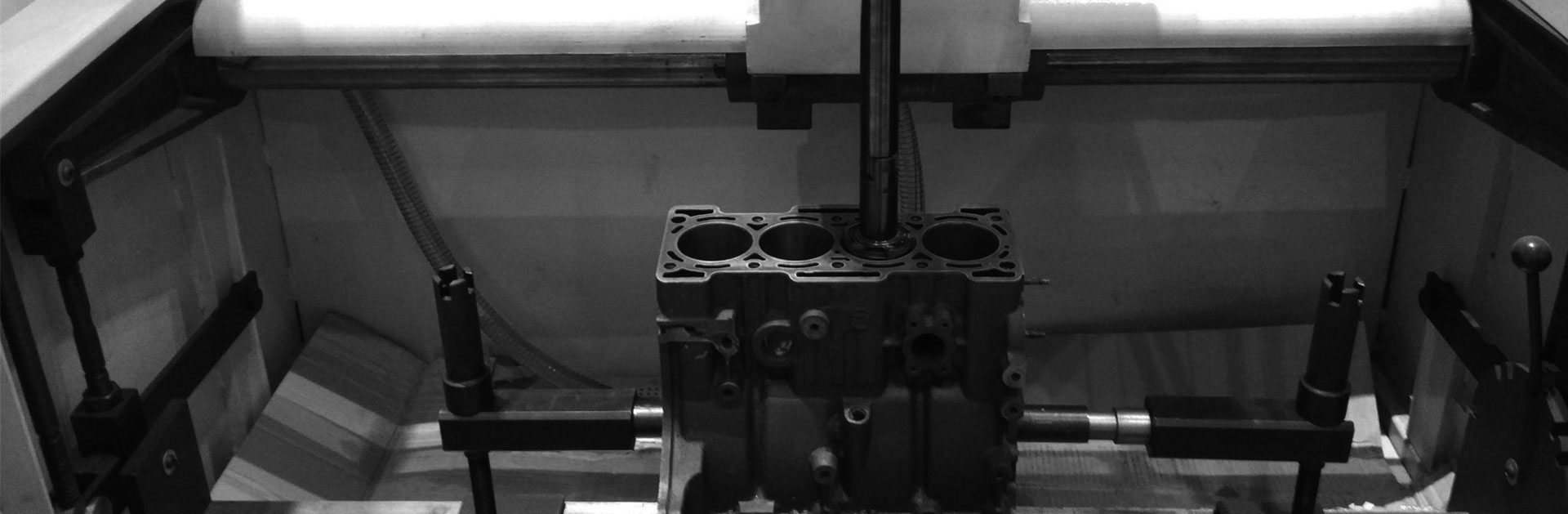

Ba za a iya yin kowane irin inji ba tare da ramuka ba. Don haɗa sassan, ana buƙatar ramuka masu maƙalli, ramuka masu rami ko ramuka masu girma dabam dabam; don gyara sassan watsawa, ana buƙatar ramuka masu hawa daban-daban; sassan injunan da kansu suma suna da ramuka da yawa (kamar ramin mai, Hanyar sarrafawa, ragin rage nauyi, da sauransu). Aikin gyaran rami don rami ya cika abubuwan da ake buƙata ana kiran shi ramin rami.

Farfajiyar ramin ciki tana ɗayan mahimman shimfidar da suka haɗu da kayan aikin inji. A cikin sassan inji, sassan da ramuka gabaɗaya sun kai kashi 50% zuwa 80% na jimlar adadin sassan. Hakanan nau'ikan ramuka sun banbanta, gami da ramuka masu rarrafe, ramuka masu raɗaɗi, ramuka masu zaƙi, da ramuka masu siffa.

Rawanin siliki na yau da kullun ya bambanta da ramuka na gaba ɗaya da ramuka masu zurfi, kuma ramuka masu zurfin suna da wuyar inji.

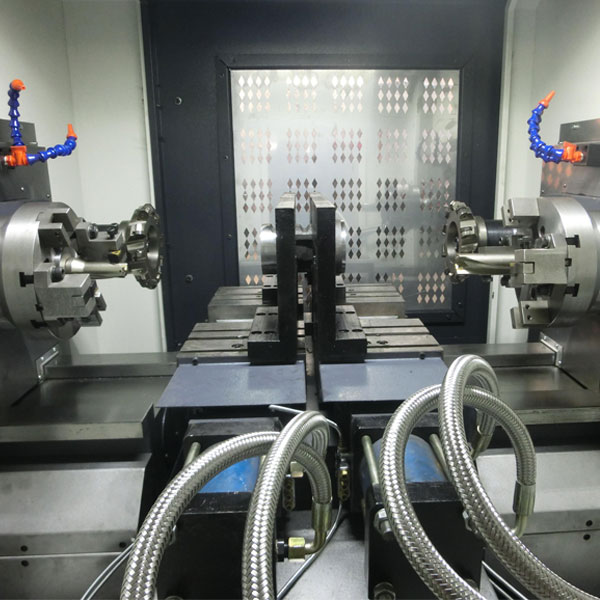

Minghe ta hakowa machining sabis da aka asali kara da cewa yabo da kuma tallafawa mu forming damar. A yau, abokan ciniki suna amfani da masana'antunmu masu jagorancin ayyukan hakora koda kuwa ba a buƙatar ƙirƙirar su ba. Tsawon shekaru 35, muna ta haɓaka ayyukanmu na hakowa don samarwa kwastomomi mafita madaidaiciya ga takamaiman aikin su. Injiniyoyin Minghe za su yi nazarin samfura dalla-dalla, fitowar kayan kira da kuma bukatun girma don zaba mafi ingancin maganin aikin hakowa.

Bukatun fasaha Don Hole hakowa

A yayin aiwatar da aikin rami, ya zama dole a guji matsaloli irin su fadada girman ramuka mai yalwace, ƙarancin farfajiyar aikin, da yawan lalacewar abin rawar, don hana tasirin tasirin hakowa da haɓaka aikin. kudin. Ya kamata a tabbatar da buƙatun fasaha masu zuwa kamar yadda ya kamata:

- - Girman girma: daidaito na diamita da zurfin rami;

- - Daidaita siffar: zagaye na rami, silinda da madaidaiciyar axis;

- - Matsayi daidai: daidaituwa tsakanin rami da axis na ramin ko axis na da'irar waje; daidaici da daidaito tsakanin rami da rami ko rami da sauran wurare, da sauransu.

A lokaci guda, ya kamata a yi la'akari da abubuwa 5 masu zuwa:

- - Tsarin zurfin rami da haƙurin farfajiyar farfajiya;

- - Halin tsarin fasalin kayan aiki, gami da kwanciyar hankali na wuce gona da iri da juyawa;

- - Gudun wuta, tsarin sanyaya da kwanciyar hankali na kayan aikin mashin;

- - Tsarin tsari;

- - Kudin sarrafawa;

Daban-daban Na Injin Hako-hako - Ana samun Ayyukan hakowa na Cnc a Minghe

Guraben rami iri daban-daban, kamar su ramuka, rami rami, ramuka masu rami, ramuka masu lanƙwasa, ramuka masu ƙwanƙwasa zagaye, da sauransu.

Ana nuna hanyoyin sarrafa da aka saba amfani dasu a cikin tebur.

| type | Content |

| Hannun Wani Sashi | Partangare guda ana huda kai tsaye gwargwadon matsayin alamar alama |

| Matukan jirgin ruwa | Tona rami a wani sashi da farko, kuma yi amfani da wannan azaman jagora don huda ramuka a wasu sassan. Ana iya amfani da wani sashi don haƙawa kai tsaye a cikin kishiyar shugabanci lokacin hakowa; Hakanan zai iya fitar da ramin rawar don yin hakar kishiyar shugabanci. |

| Haɗuwa hakowa | Don tabbatar da nisan ramin sassan, za a iya haɗa sassan biyu tare da ɓoyayye iri ɗaya ko a haɗa su da dunƙule don samar da duka, kuma ana iya huda ramuka a lokaci guda bisa ga alama. |

Reaming inji

Sau da yawa akwai wasu ramin fil, ramuka masu cirewa, ramuka masu gyara, da dai sauransu a cikin sifofin da ake buƙatar sarrafa su bayan rubutun ko lokacin taro. Daidaitawar aiki gabaɗaya IT6 ne zuwa IT8, kuma ƙarancin aiki bai gaza Ra3.2μm ba.

Janar ka'idoji na reaming

| type | Content | |

| Diamita na aiki | An kwashe shi kuma an sake shi ta hanyar fitter | |

| 10 ~ 20 | Gudanarwa ta hanyar haƙawa, sake tunani, sakewa, da dai sauransu. | |

| > 20 | An riga an sarrafa shi ta wurin rawar motsawa, sannan gyaran inji da aikin inji mai gundura | |

| Bukatar kashe ramin | Lokacin sakewa, adadin nika ya zama 0.02 ~ 0.03. Ya kamata a kiyaye ramuka yayin maganin zafi kuma za a sake yin ƙasa yayin haɗuwa | |

| Haɗuwa da reaming na abubuwa daban-daban | Lokacin reaming sassa na kayan daban, yakamata a sanya reaming daga kayan wuya | |

| Hardening hardware reaming | Ta hanyar sake jujjuyawar ramin kayan aikin, da farko a duba ko ramin ya lalace, sake sakewa tare da daidaitaccen siminti carbide reamer, ko sake sakewa tare da wani tsohon reamer, sannan a yi amfani da sandar nika ta ƙarfe don niƙa zuwa girman da ake buƙata | |

| Reamed rami | Lokacin da ba a sake juya ramin ba, ya kamata zurfin ramin sake sakewa, barin tsawon sashin yankan reamer don tabbatar da ingancin diamita na ramin; Hakanan za'a iya sake masa suna tare da daidaitaccen reamer, sannan a sake ramin ramin tare da wani tsohon reamer wanda ya faɗi ɓangaren yankan. Unhinged kasa | |

| Injin inji | Bayan an daddafe kayan aikin sau daya, ana gudanar da aikin hakowa, sake tunani, da kuma sakewa don tabbatar da daidaito da kuma daidaiton ramin | |

Injin Rami Mai Zurfi

Ramin tashar sanyaya, ramuka masu zafi da wani ɓangare na ramin ejector fil a cikin filastik filastik suna buƙatar yin rami mai zurfi. Gabaɗaya, daidaiton rami mai sanyaya ba mai yawa bane, amma ya zama dole don hana ɓatarwa; don tabbatar da ingancin canjin zafi, ramin hita yana da wasu buƙatu don ramin rami da kaushin jiki, ramin diamita ya fi 0.1 ~ 0.3mm girma sama da sandar dumama, kuma kaurin yana Ra12.5 ~ 6.3 μm; yayin da ramin ejector ke buƙatar matsayi mafi girma, cikakken daidaito shine IT8 kuma akwai buƙatun don tsayayyar jiki da tsaurarawa.

Aikin rami

Ana buƙatar ramuka da yawa a cikin sifar don tabbatar da nisan ramin, tazarar gefen rami, daidaici na kowane rami, daidai da ƙarshen fuska, da haɗin gwiwar ramuka bayan an haɗa sassan biyu. Wannan nau'in tsarin ramin gabaɗaya ana sarrafa shi da farko, sannan ana sarrafa ramuka ta hanyar yin rubutu.

Zaɓi Mafi Kyawun Tsarin Hakowa

Bayan bincika jerin ayyukan Kula da Surface, zaɓi tsari dangane da mahimman lamuran, kamar lokacin ƙira, ƙimar farashi, haƙurin ɓangare, karko da aikace-aikace. Mahimmancin haƙuri na CNC, sassa masu juyawa ba'a da shawarar yin amfani da ƙarshen ƙarfe na ƙarfe na biyu, saboda jiyya na iya canza girman girman ɓangaren da aka gama ta cire ko ƙara ƙananan adadin kayan.

Tuntube mu ko Imel sales@hmminghe.com don ganin yadda mutanenmu, kayan aiki da kayan aiki zasu iya kawo mafi kyawun inganci don mafi kyawun farashi don aikin hako ramin ku.