Haɗuwa Da Gwaji

MAJALISI DA GWAJI

Ci gaban Majalisar Minghe

Minghe Die Casting yana ba da sassauƙa, mafita mai sauƙi mai sauƙi tare da samar da ƙaramin taro da ƙararrun majalisai.

Mu a MINGHE CASTING muna da kayan aiki da ƙwarewa don yin yawancin taro da gwaji. Tabbatar da Samfurin Samfur don tabbatar da mafi girman ingancin, tare da ingantaccen juyawa sau amfani da layukan taro don adadi mai yawa.

Daga sauƙin haɗarin inji da gwajin matsi, zuwa haɗuwar lantarki da gwaji tare da mai nazarin cibiyar sadarwa. Wannan zai ba ka damar siyan samfurin da aka ƙare maimakon kawai abin haɗi.

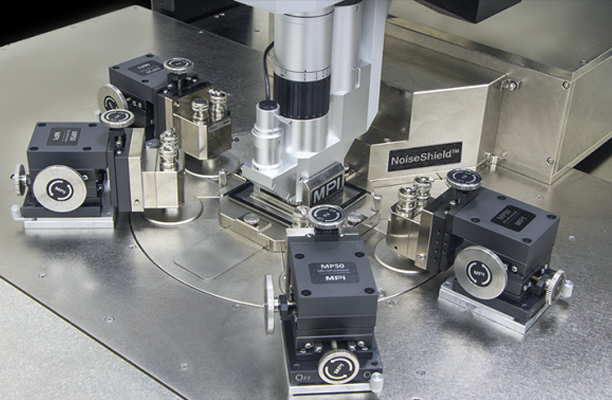

Ana amfani da kayan gwajin lantarki don ƙirƙirar siginar motsa jiki da kama martani daga Na'urorin lantarki. Aikin da ya dace da na'urar lantarki ana iya tabbatarwa ko kuskure a cikin na'urar, wanda za'a iya gano shi da gyara shi. Amfani da kayan gwajin lantarki yana da mahimmanci ga kowane nau'in aiki akan tsarin lantarki.

|

|

|

|

Attoƙarin Mu Da Foroƙarin Mu Don Assemblyarin Majalisa Mai Sauƙi

Ko kuna buƙatar shigar da kayan aiki mai sauƙi ko haɗuwar injiniya mai rikitarwa, Minghe Die Casting na iya samar da tanadin lokaci, ayyuka masu tsada don aikin ku. Muna sarrafa cikakken aikin ku daga samfur, jefa simintin gyare-gyare, ƙera kayan masarufi, sayan kaya, da haɗuwa. Hakanan za mu iya samar da kayan kwalliyar ƙananan sassan da aka tara don layin samarwar ku da kayan gyara. Daga ƙananan assemban majalisun injina zuwa hadaddun keɓaɓɓun keɓaɓɓu na lantarki, muna daidaita hanyoyin taro don ainihin bukatunku.

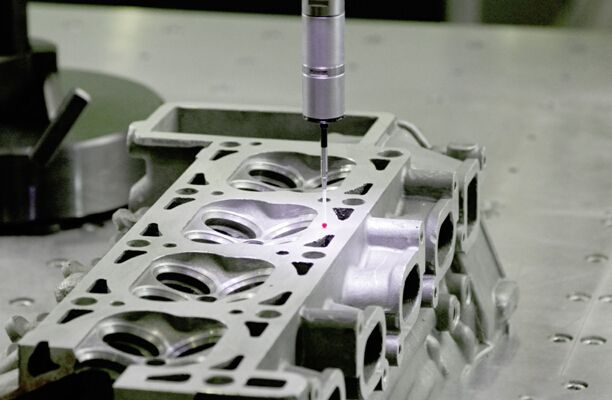

1. Tsarin Marigayi Mutuwa

Tare da fadi da aikace-aikace na CNC machining fasahar, da wuya na tsarin da ya mutu simintin gyaran kafa ci gaba da kara. A yayin sarrafa wasu simintin gyaran kafa, sanyawa da matsewa suna da matukar wahala, kuma basu dace da sanya wuri da yawa ba. Fasahar kere-kere guda daya mai dauke da kayan aiki gaba daya shine juyawa da juya teburin aiki gwargwadon kusurwar kan mashin din cibiyar mashin din da ke kwance ko a tsaye-a kwance don aiwatar da dukkan fuskoki da ramuka na bangaren jefa-mutu a wani lokaci, kuma sannan hadu da dukkan bukatun halayyar zane na zane. Bangaren da aka haɗa tare da maɓallin aiwatarwa yana da layi da milled don raba sarrafawar aiki daga abin ɗora hannu.

2. Ka'idar Aiki

Yi cikakken amfani da fa'idodi masu amfani da kusurwa da yawa da kuma aiki na cibiyar mashin ɗin CNC, yi amfani da halaye na mai yankan mashin don sarrafa sassa tare da ƙananan nakasa a cikin babban hanzari da ƙaramar abinci, yi amfani da ɓangaren ɓangaren ɓangaren bayanan martaba kamar Matsayi da matattarar aiki, da amfani da software na UG zuwa atomatik Ayyukan shirye-shiryen suna tabbatar da daidaiton sassan sassan da aka sarrafa da kuma kyakkyawan haɗin kan dukkan ɓangarorin.

3. Tasirin Aiwatarwa

-Angarorin mutu-simintin gyare-gyare suna ɗauke da kayan haɗin kai da fasahar kera lokaci ɗaya. Lokacin da aka samar da sassan simintin gyaran jiki, bayan dubawa uku-hade, bayanan kididdiga na fasali da daidaiton matsayin sune kamar haka: K flat flatness flatness ≤ 0.012mm, M flat flatness ≤ 0.01mm, M backside layi daya The degree of -0.015mm, daidaituwar φ30mm zuwa tushe M shine -0.013mm, daidaitaccen φ32mm zuwa tushe na K shine -0.015mm, mahaɗan φ30mm da axis φ32mm shine -0.014mm. A cikin samar da taro, sifa da daidaitattun wurare na sassan tsayayye ne, kuma ƙwarewar samarwa yana haɓaka ƙwarai.

4. Aikace-aikace Da Fadada

Za'a iya amfani da fasahar aiwatar da lokaci daya ta kayan kwalliyar sassan sassan ba wai kawai a cibiyoyin kere-keren kwance ba, har ma a cibiyoyin gyaran inji na tsaye da kuma a tsaye. Za'a iya sarrafa sassan mutu-simintin kuma a kirkiri su a mataki daya akan cibiyar sarrafa axis-axis guda biyar, kuma za a iya milke aikin sarrafawa cikin layuka; Za'a iya sarrafa sassan simintin gyare-gyare ta wani faranti mai jujjuya akan cibiyar injunan axis uku. Don cire ragowar tsarin aiki.

5. Aikace-aikacen Gabaɗaya

Fasahar tsari ta zamani daya hada kayan kwalliyar sassa akasari ana amfani dasu wajen sarrafa sassan tare da sanya matsatsi da matsewa. Ana iya haɗuwa da hanyoyin sarrafawa don haɓaka ƙimar aiki da tabbatar da daidaitattun sifa da matsayi; ana iya amfani dashi don saukakar yankan ɓangarorin tsarin daidaitaccen don rage yawan matsewa, Adana farashin kayan aikin samarwa; dace da sauri-sauri da ƙananan abinci na aikin sarrafa Layer ta Layer, yankan ƙarfin ƙananan ne, yankan zafi ƙanana ne yayin aiki, kuma ɓangarorin -an wasa masu mutuƙar ba sa fuskantar matsalar nakasawa. Wannan ra'ayin aikin ana samun ci gaba sannu a hankali a masana'antar jefa-matattu.

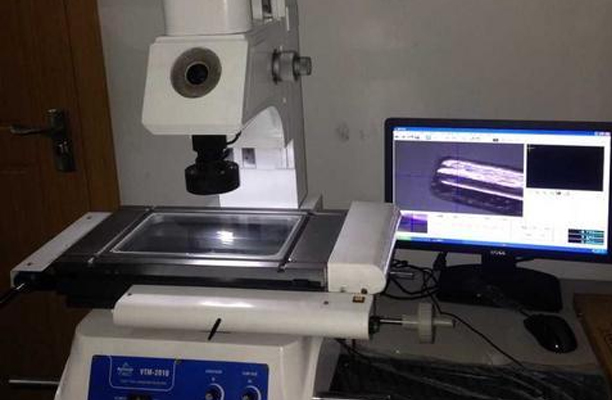

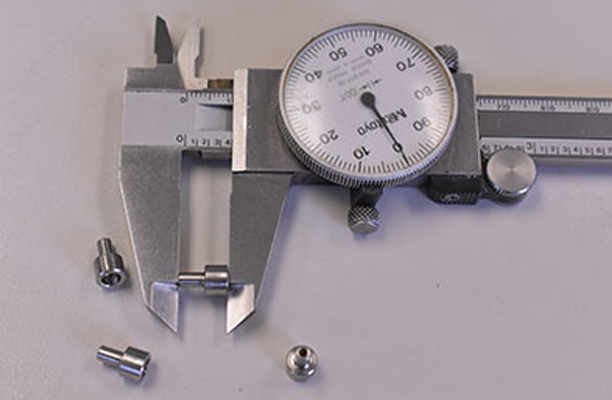

Jerin Kayan Aikinmu na aunawa

|

|

|

|

|

|

|

|

|

|

|

|