Nazarin Wavelet na Ragewa a cikin Siffofin Fassara Kyauta CNC Machining

Ana amfani da adadi mai yawa na kayan aiki kamar kayan mashin CNC da cibiyoyin sarrafa kayan masarufi. Tsarin masana'antu yana da tsawo. Masu aiki suna fuskantar gajiya. Da zarar gazawa ta auku, yakan ɗauki 'yan kaɗan daga hangen nesa na ɗan adam don ɗaukar matakan da suka dace, wanda na iya haifar da tarkacen kayayyaki, Wanda ke haifar da asara mai yawa na tattalin arziki. Akwai rahotanni da yawa na cikin gida da na ƙasashen waje akan ɓarnar kayan aiki da gano kuskuren inji a cikin aikin sassan gaba ɗaya. Mafi yawansu sun fi mayar da hankali ne kan fitar da iska, karfin yankan ko sa ido game da jijjiga, da sauransu, kuma an sami ci gaba sosai. Koyaya, aikin yana da rikitarwa. Molds da sauran kayan aiki tare da sifofin sifa iri-iri har yanzu basu da ingantaccen fasahar sa ido. Dalilin shi ne cewa siginar da aka yanke da wuyar ganewa. Wani shine don samar da ingantattun hanyoyi don saka idanu na ainihi. Wannan labarin yana amfani da kayan aikin sarrafa sigina na yanzu-nazarin raƙuman ruwa. Ana yin duban "Maida hankali" akan lokaci daban-daban da maɗaikun madogara na siginar asali don cire siginar da aka yanke daga lokaci-mitar lokaci. 1 Manufar nazarin Wavelet Binciken Wavelet shine ci gaban nazarin Fourier. Yana amfani da Xu Shuxin et al.: Gudanar da lambar adadi na kyauta na kyauta Wavelet na yanke-yanke a cikin sarrafawa Aikin igiyar ruwa mai ɗorewa na aiki kb (t) ana amfani dashi azaman aikin canji mai mahimmanci. Don mitoci daban-daban, ana canza taga lokaci ta atomatik lokacin da aka bincikar halayen mitar kuma aka gano su gwargwadon faɗaɗawa da ƙanƙantar ma'aunin sikelin a (an rage) Yayin da ake bincika da gano halaye masu ƙarancin mita (ƙari), da taga lokaci yana fadada ta atomatik, kuma taga mitar ta taƙaita ta atomatik, wanda ya fahimci canjin canji na taga-mitar lokaci don lokuta daban-daban. Za'a iya canza tushen aikin. Zamar da kangon lokaci, domin ku iya bincika kowane bayani game da sigina a kowane lokaci.

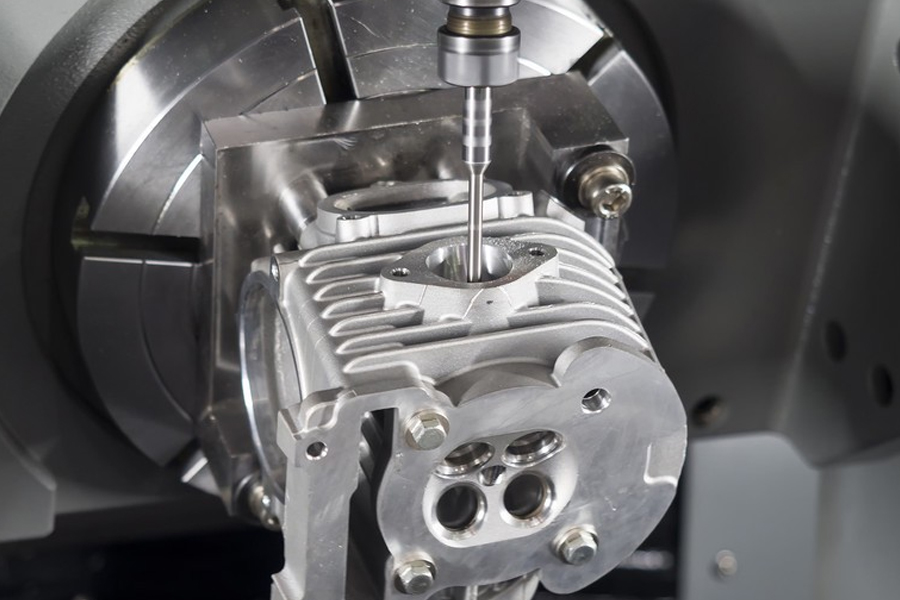

2 Ka'idodin nazarin Wavelet na siginar wuce gona da iri a cikin aikin samfuran kyauta. A cikin aikin CNC, ana kiran mahaɗan ƙarshen fuskar kayan aiki da farfajiyar kayan aiki a kan yanke-yanke. Yana da yankan yankan al'ada. Lokacin da farfajiyar kayan aikin kyauta ta wuce gona da iri, sai karfin yankan ya canza ba zato ba tsammani, wanda hakan zai haifar da Sauyin karfin yankan, da kuma motsin da yake tura kayan aikin shima zai canza. Sabili da haka, saka idanu game da canjin motar tare da ƙarfin yankan zai iya saka ido kan matsayin kayan aiki a kaikaice kuma cire siginar ta yanzu daga motar spindle. Hanyar mafi sauki ita ce ta yin I / tare da juriya na jeri. U canzawa, fitarwa a cikin hanyar ƙarfin lantarki, amma ƙari na juriya yana canza halayen kaya na motar kanta, wanda ya rage daidaiton ma'auni. Bugu da kari, sauran kayan aikin da aka hada a kowane bangare na mahimmin juriya dole ne a canza su daidai don dakatar da damar ta, wanda babu shakka yana kara rikitarwa na tsarin auna. Dangane da wannan, wannan takarda tana amfani da ma'aunin maganadisu mai auna firikwensin halin yanzu. Sensor din kanta an haɗa ta da wutar lantarki ta DC. An samar da filin maganaɗisu a cikin ɓangaren Hall. Lokacin da tashar shigarwar motar ta yanzu ta haɗu da firikwensin, ana samarda halin yanzu a tashar fitarwa. Yana haifar da daidaitaccen filin maganaɗisu a cikin ɓangaren Hall. Idan halin motsin ya canza, tasirin magnetic zai daidaita. Don samun sabon daidaituwa, dole ne a canza yanayin fitarwa daidai. Saboda hall ɗin Hall yana da kyakkyawar alaƙar linzami tsakanin shigarwa da fitarwa, jujjuyawar siginar fitarwa na iya kai tsaye ya nuna canjin motar. Saita siginar fitarwa Shin f (t), to ana iya fassara maƙallan raƙuman ruwa na f (t) azaman ƙididdigar ƙuduri mai yawa na samfurin ciki na f (t) da,) (, aikin sikelin daidai ne 1, don haka ya kamata kuma a sami tushen aikin V / sarari A cikin sararin V / + i, ana iya amfani da tushen ƙa'idodin yanki na V / + i don bayyana kusancin 1 da 2'da kyau a cikin tsinkayen V / + i da V /. Dangane da ka'idar hangen nesa, ƙuduri Alamar daki-daki na 2's zai zama tsinkayen orthogonal na sigina na asali akan sararin samaniya mai haɗin gwiwar V / game da V + 1. Bari wannan sararin da ya dace ya zama W /, ma'ana, asalin aikin W / sarari 2 / (x -2 / n) yakamata ya kasance a cikin sararin V / + i, don haka tsarin ƙa'idar tsarin mulki na al'ada (5) a Hakanan ana iya amfani da sararin V + 1 don nuna sigina / (t) GV + 1, to sai tsarin da ke sama ya nuna cewa f (Za a iya samun kusancin Af na t mai ƙwarewa daga ƙimar kusanci mai ƙarfi Ad + i / wuce tace. Hakanan za'a iya samun sigina d / f na f (t) dalla-dalla daga ƙimar kusanci Ad-i / wuce wani matattara. Tace h (n) g (n) an bayyana ta samfurin ciki na aikin haɓaka h (t) da aikin raƙuman ruwa ⑴.

Don siginar dijital da aka samo samfurin ta kwamfuta, siginar dyadic ƙaramar hanya ce. Kayan aiki 2 kayan aiki suna da yiwuwar faruwa. Don sauƙaƙe tsarin gwajin yayin la'akari da mahimman halaye na yin sara, wannan labarin ya aiwatar da gwajin ƙwanƙwasa juzu'i kamar yadda aka nuna. Yawan samfurin shine 1kHz.3.1 Yanayin gwajin don yawan yin gwaji kamar haka: diamita na mai yankan inji shine 8mm, zurfin yankan shine 1mm, saurin spindle n = 500r / min, saurin abinci shine v = 150mm / min, zurfin wuce gona da iri shine Hg = 0.05mm, kayan aikin shine A3 karfe, kuma kayan aikin kayan ƙarfe ne mai sauri. Alamar da aka auna kamar yadda aka nuna a cikin S a cikin siginar da aka yanke da raƙuman raƙuman ruwa. Ana iya ganin cewa siginar lokaci-yanki ta fi rikitarwa, kuma babu bayyanannen fasalin da aka yanke. Misali, lokacin da aka lura a cikin yankin mitar, ba za a iya samun nasarar sa ido na ainihi ba saboda rashin sanyawa a yankin lokaci. burin. Sabili da haka, siginar da aka auna ta asali tana fuskantar bazuwar raƙuman ruwa, kuma an lasafta sakamakon canji a cikin sakamakon canji. Ana iya gani daga sakamakon canzawa cewa lokacin da overcut ya auku, yin tunani akan ƙaramin sikelin (babban mita) ba bayyane bane, amma fasalin wuce gona yana bayyane akan sikeli na huɗu. Yana nuna cewa a cikin ainihin sa ido, ana iya saita ƙofa a kan wannan sikelin don gano yanayin yankan, kuma maɓallin giciyersa yana daidai a cikin duka madaidaitan lokaci-lokaci a cikin zanen canzawa na igiyar ruwa, wanda ya dace da saka idanu na ainihi. . 3.2 Gwajin yankewa Yanayi biyu na gwaji: yankan milling diamita shine 10mm, yankan zurfin = 0.5mm, saurin dunkule n = 500r / min, saurin abinci v = 150mm / min, zurfin over1 QXNUMXmm, kayan aiki mai kyau shine Ruwa, kayan aikin kayan aiki shine karfe mai sauri Ana iya ganin siginar da aka auna da bazuwar raƙuman ta daga adadi. Ana iya gani daga adadi cewa ƙarshen yanki ba a bayyane yake ba a cikin kewayon mitar tsayi. Har ila yau, a kan sikelin na huɗu, ana nuna fasalin kan-yanki a fili. 4 Kammalawa Wavelet ya canza zuwa sauƙaƙan lokaci-lokaci na siginar Yana ba da tushe na lissafi, ya ɗauki hanyar nazarin raƙuman ruwa, zai iya nazarin siginar daga yankin lokaci da mitar lokaci a lokaci guda, da aiwatar da madaidaicin lokacin-mitar matsayi na maki na sha'awa. A cikin kayan aikin NC na kayan aikin kyauta na kayan kwalliya, yawan yin abu hanya ce ta gazawa gama gari. Matsayin shigarwa ya ƙunshi wadataccen bayani na mita, amma yana da wahala a sami ingantaccen bayani game da yankan kai kawai daga lokacin lura yankin. Binciken Wavelet na iya kiyaye siginar a lokuta daban-daban da sassa, kuma zai iya cire bayanai daban-daban daidai game da yanayin maye gurbin mitar. Yana nuna cewa a lokaci, sararin samaniya yana amfani da sikanin "mai da hankali" don kiyaye bayanan yankan hanya. Kodayake yin tunani ba bayyane bane a cikin wasu mitocin mitar, a cikin wasu maɗaukakan mitar, ƙimar ƙarfin rawanin rawanin a bayyane yake sananne, wanda zai iya gano yanayin yankan kayan aiki da kyau a ainihin lokacin.

Da fatan za a adana tushe da adireshin wannan labarin don sake bugawa: Nazarin Wavelet na Ragewa a cikin Siffofin Fassara Kyauta CNC Machining

Minghe Kamfanin 'Yan Wasa Masu Mutu aka sadaukar domin tsirar da samar da inganci da kuma high yi Gyare sassa (karfe mutu simintin sassa Range yafi hada da Thin-Wall Mutu Wasa,Hot Chamber Mutu Wasa,Cold Chamber Mutu Wasa), Zagaye Sabis (Mutuwar 'Yan Wasa,CNC machining,Motsa Motsa, Jiyya na sama) .Adadin al'ada Aluminium ya mutu, magnesium ko Zamak / zinc mutu simintin gyare-gyare da sauran buƙatun simintin maraba don tuntube mu.

Karkashin kulawar ISO9001 da TS 16949, Ana aiwatar da dukkan matakai ta hanyar daruruwan injunan jefa simintin da suka mutu, injunan axis 5, da sauran kayan aiki, tun daga masu fashewa zuwa na’urar Ultra Sonic masu wanki.Minghe ba kawai tana da kayan aiki na zamani ba amma kuma tana da kwararru ƙungiyar ƙwararrun injiniyoyi, masu aiki da sufetoci don tabbatar da ƙirar abokin ciniki ta zama gaskiya.

Manufactureran kwangilar masana'antar mutu. Abubuwan haɓakawa sun haɗa da sassan sanyi na sassan mutuɗar aluminum daga 0.15 lbs. zuwa 6 lbs., saurin canje-canje da aka saita, da aikin inji. Sabis-ƙarin ayyuka sun haɗa da gogewa, faɗakarwa, lalatawa, fashewar harbi, zane, zane, rufi, haɗuwa, da kayan aiki. Abubuwan da aka yi aiki tare sun haɗa da allo irin su 360, 380, 383, da 413.

Zinc ya mutu don jefa ƙirar ƙira / sabis na injiniya tare. Custom manufacturer na daidaici tutiya mutu simintin gyaran kafa. Castananan 'yan simintin gyare-gyare, pressurean ƙwanƙwasa masu juzu'in juzu'in simintin gyare-gyaren juzu'ai, ƙera simintin gyare-gyare na al'ada, ɓangaren mutu da' yan wasa masu mutuwa masu zaman kansu da ƙofar da aka hatimce za a iya ƙera su. Za'a iya kerarrar 'yan simintin a tsayi da faɗi har zuwa 24 a ciki. A cikin +/- 0.0005 a cikin. Haƙuri.

ISO 9001: 2015 bokan masana'anta ta mutu magnesium, Abubuwan haɓaka sun haɗa da matsin lamba na magnesium mai matsi mai yawa har zuwa tan 200 mai ɗumi mai zafi & 3000 ton mai sanyi, ƙirar kayan aiki, gogewa, gyare-gyaren, inji, foda & zanen ruwa, cikakken QA tare da damar CMM , taro, marufi & isarwa.

ITAF16949 bokan. Servicearin Sabis ɗin Gyare Hadawa zuba jari,yashi,Kushin nauyi, Stauren ɓoye ɓoye,Siffar Centrifugal,Cast Vacuum,Dindindin Mould Gyare, .Hanyoyin iyawa sun hada da EDI, taimakon injiniya, ingantaccen samfuri da aiki na sakandare.

Fitar Masana'antu Abubuwan Nazarin sassa don: Motoci, Bikes, Jirgin sama, kayan kiɗa, Jirgin ruwa, Na'urorin hangen nesa, na'urori masu auna sigina, na'urori masu auna sigina, Na'urori, Kayan lantarki, ,unshi, Clocks, Inji, Injiniya, Kayan Kaya, Kayan Jiki, Jigs, Telecom, Haske, Kayan aikin likita, Na'urar daukar hoto, Robobi, Sassaka, kayan sauti, kayan wasanni, Kayan aiki, Kayan wasa da ƙari.

Me Zamu taimake ku yi gaba?

Je zuwa Shafin Farko Don Mutu Wasa China

→Sassan Kasuwanci-Gano abin da muka aikata.

→ Tallan kwankwasiyya Game da Ayyukan Gyare Mutuwa

By Minghe Mutu Wasa Wasa | Categories: Labarai masu Taimakawa |Material Tags: Gyare Aluminum, Zinc Gyare, Fitar Magnesium, Castan Wasanni, Bakin Karfe Cast, Fitar tagulla,Gyare Tagulla,Fitar Bidiyo,Tarihin Kamfanin,Aluminum Mutu Gyare | Comments Off