Menene Gwajin Moda Don Gyara Siminti

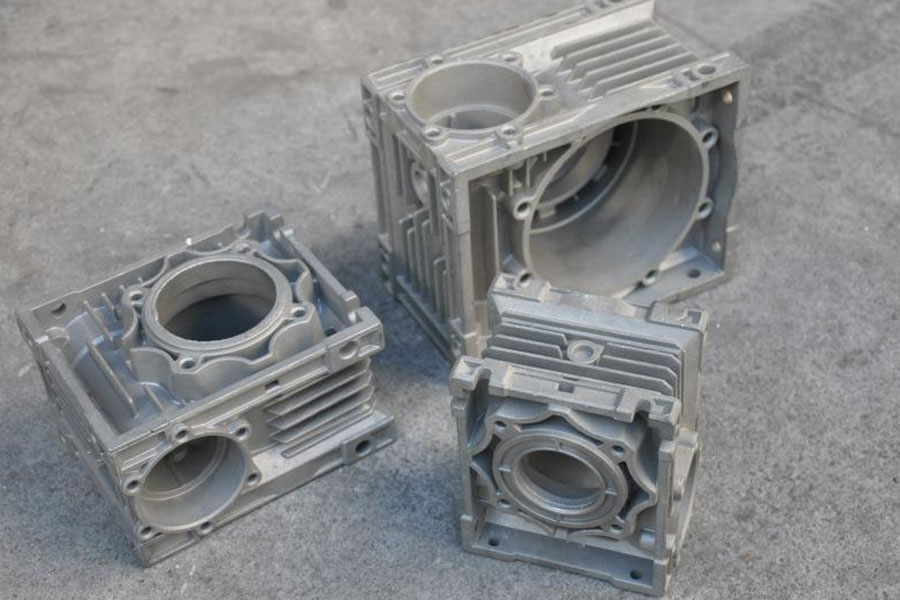

Mutuwar simintin gyare-gyare shine tsarin tabbatarwa na ainihin samarwa da ƙirar ƙirar, kuma shima muhimmin tsari ne na ƙirar mutuƙar, kayan aiki, haɓaka tsari da daidaitawa zuwa samar da taro. Wannan labarin galibi yana gabatar da tsarin ƙirar ƙirar don tabbatar da gwajin gwaji da haɓakawa da daidaitawa na gaba.

A cikin mataki na mutu-simintin sabon haɓaka samfur da sabon gwajin ƙirar, za a sami ƙarin matsaloli ko kaɗan waɗanda ke haifar da gazawar gwajin. Kuma akwai abubuwa da yawa waɗanda ke shafar gazawar gwajin samfurin. Menene abubuwan da suka dace?

Da farko, yin bita da nazarin tsarin simintin gyare -gyare da ƙera tsarin ƙira a matakin ci gaba. Abu na biyu, sigogin tsari na samar da mutuƙar simintin ƙarfe kamar zubin ƙarfe na ƙarfe, matse-matsewa, saurin gudu da saurin juyawa daidai ne. Da sauransu, wasu dalilai sune mabuɗin don yin tasiri kai tsaye da ingancin ƙimar simintin ciki da waje.

Amma a mafi yawan lokuta, ƙirar ƙira da samarwa suna da alaƙa da juna. Abubuwan da ke shafar ƙirar, gami da adadin ramuka, ƙirar tsarin ƙofar, nau'in ƙofar (matsayi, yanki, alkibla), da sauransu, don simintin gyare-gyare tare da manyan banbancin kauri, babban matsin lamba na sanyaya gida da ainihin Hakanan ana amfani da sanyaya. Don cimma manufar daidaita yanayin zafin jiki. Kawai tare da kyakkyawan ƙirar ƙirar za a iya samun madaidaicin sigogi na tsari, wanda ya fi dacewa da ingancin ciki da waje na simintin gyare -gyare. Don takamaiman bita da bincike, dole ne mu yi amfani da wasu software na taimako. Misali: software na bincike na kwararar ruwa, software na sarrafa saiti na tsarin PQ 2 da sauransu.

Nazarin Bayanan Bayani

1) Yi nazarin ƙirar farko na wurin ƙofar, yanki da alkibla, wurin murfin jakar slag, da sauransu ta hanyar software mai kwararar ruwa. Fahimci ƙwanƙwasawa, rarraba zazzabi, hanyar kwarara da hanzarin ƙarfe mai narkewa da ke gudana a cikin rami, da tarin tarin slag da shaye -shayen jakar slag, da gano matsalolin don samar da tushe don bita da gyare -gyare na gaba, don haka don samun Ingantaccen tsarin ƙofar.

2) Yin amfani da zane na PQ 2 don saka ƙirar, kayan aiki da sauran ƙididdigar sigogi, da farko za mu iya saita sigogi na tsari da kuma sahihancin zaɓin tonnage, gano matsalolin cikin saitunan siginar tsari da gyara su cikin lokaci; kuma za mu iya kuma samun ka'idar The sama tsari sigogi da shiryar da muhimmanci ga daidaita da tsari sigogi na mutu simintin inji.

Mutu Fitar Mold Trial Kuma Tsari Sigogi ingantawa

Babban maƙasudin gwajin ƙirar shine gano ingantattun sigogi na aiwatarwa da tsarin gyaran mold. Ana buƙatar cewa koda kayan, saitunan injin ko abubuwan muhalli sun canza, har yanzu yana iya tabbatar da cewa ƙirar zata iya tsayawa cikin tsayayye kuma ba tare da katsewa ba ta samar da samfuran ƙwararru a ƙungiyoyi. Inganta "daidaitawa" na kwandon zuwa iyakance, ba don kawai samun samfuran samfuran samfuran gwaji masu kyau ba.

Aikin shiri kafin gwajin mold. Dangane da zane -zanen ƙirar, yi cikakken binciken abubuwan da suka dace (musamman girman keɓaɓɓiyar keɓancewar busruka); gano jerin ayyukan kowane sashi mai motsi na sifa (jan jan da darjewa); tabbatar da abin da za a yi amfani da shi Na'urar injin simintin mutu, matsayin allura, keɓaɓɓen bututu, diamita ɗakin matsa lamba da girman keɓaɓɓen suna daidai da ainihin buƙatun ƙirar. Dole ne a biya kulawa ta musamman ga injin mutu-simintin da aka yi amfani da shi a cikin ƙirar gwajin dole ne ya dace da ƙirar injin mutuƙar da aka yi amfani da shi wajen samar da injin, in ba haka ba ƙirar na iya zama mara amfani.

Dangane da sigogin tsarin ka'idar da aka samo daga ginshiƙi na PQ2, ana gudanar da gwajin gwaji don nemo bambanci tsakanin ainihin sigogi da ka'idoji. Kuma ci gaba da daidaitawa da gyarawa, har sai an sami ingantaccen simintin gyare-gyare tare da kyakkyawan ingancin ciki. Daga cikin su, aikin 'yan jaridu na iya zama maras tabbas, wanda ke sa ya yi mana wahala mu yanke hukunci kan matsalar. A wannan lokacin, ana iya amfani da "mai duba allura" don lura da saurin, matsin lamba, ƙaura da sauran sigogi a cikin aikin allura, da yin hukunci ta hanyar jujjuyawar lanƙwasa. Taimaka mana daidai gano matsalar, yadda yakamata ya jagoranci gyara sigogi na aiwatarwa da fahimtar aikin kayan aiki. A ƙarshe, za a sami saiti mafi kyawun sigogi na tsari wanda ya dace da wannan kayan aikin.

Abubuwan da masana'antar kera ke samarwa galibi saboda ƙarancin ƙirar ƙira ko aiki mara kyau a cikin tsarin samarwa. Sau da yawa akwai wasu matsaloli, kamar rashin haƙuri, jujjuyawar cikin gida mara kyau, tsarin da bai dace ba, da tsarin sanyaya ruwa mara ma'ana. Babban bambancin zafin jiki, da sauransu, wanda ke haifar da simintin gyare -gyaren da ba a cancanta ba ko gazawar samar da gwajin gwaji. Saboda banbanci tsakanin sakamako na zahiri da ka'idar, gwajin ƙwayar cuta shine hanya mafi sauƙi, kai tsaye kuma mai inganci don gano matsalolin mold. Hakanan kuna iya sanin rarraba zazzabi na ƙirar kuma ko wurin sanyaya ruwa yana da ma'ana ta hanyar hoton hoton zafi, wanda yana da matukar taimako don tsawaita rayuwar ƙirar. Hakanan yana da mahimmancin jagora don daidaita fesawa.

A cikin tsarin ƙirar gwaji, sassan ƙirar gwajin da aka samar bayan an daidaita sigogi na tsari suna buƙatar yin bita a kan site ta injiniyoyin samfur, masu fasaha da injiniyoyi masu inganci gwargwadon buƙatun abokin ciniki. Babban abun ciki na bita shine:

- Auna mahimmancin girma da auna girman farfajiyar farfajiya;

- Ko gyaran siffar kwatankwacin simintin gyare -gyare ba daidai ba ne, ko layin rabuwa ba daidai ba ne, ko akwai rauni, tsagewa, raguwa, da sauransu;

- Anatomy da X-ray dubawa don duba porosity da ƙuntatawa a cikin simintin. Fahimci matsayin ingancin simintin gyare -gyare da matsalolin ƙirar ta hanyar bita na farko, da samar da tushe da jagora don gyara daga baya.

Mutuwar simintin gyare-gyare ba kawai tsari ne na asali da na asali da tabbaci ba, har ma tsari ne na ci gaba da gyara kuskure da haɓakawa. Haka kuma, mutuƙar simintin zamani yana da ƙarin software na kayan aiki da kayan aiki na zamani don taimaka mana gwada ƙyallen a kimiyyance. Yi nazari na yau da kullun game da tsarin simintin gyare-gyare, tsarin ƙirar, tsarin kashe-mutu da aiwatar da kayan aikin mutu-mutu don gano bambance-bambance da matsaloli. Bayan an warware matsalar, an inganta tsarin ƙirar da sigogin aiwatarwa. Sanya nunin mu ya fi dacewa don samar da tsayayye da ingantaccen kulawa. Wannan yana cike da mahimmancin gwajin ƙirar mutuƙar simintin.

Da fatan za a adana tushe da adireshin wannan labarin don sake bugawa: Menene Gwajin Moda Don Gyara Siminti

Minghe Gyare Company aka sadaukar domin tsirar da kuma samar da inganci da high yi Gyare sassa (karfe mutu simintin sassa Range yafi hada da Thin-Wall Mutu Wasa,Hot Chamber Mutu Wasa,Cold Chamber Mutu Wasa), Zagaye Sabis (Mutuwar 'Yan Wasa,CNC machining,Motsa Motsa, Jiyya na sama) .Adadin al'ada Aluminium ya mutu, magnesium ko Zamak / zinc mutu simintin gyare-gyare da sauran buƙatun simintin maraba don tuntube mu.

Karkashin kulawar ISO9001 da TS 16949, Ana aiwatar da dukkan matakai ta hanyar daruruwan injunan jefa simintin da suka mutu, injunan axis 5, da sauran kayan aiki, tun daga masu fashewa zuwa na’urar Ultra Sonic masu wanki.Minghe ba kawai tana da kayan aiki na zamani ba amma kuma tana da kwararru ƙungiyar ƙwararrun injiniyoyi, masu aiki da sufetoci don tabbatar da ƙirar abokin ciniki ta zama gaskiya.

Manufactureran kwangilar masana'antar mutu. Abubuwan haɓakawa sun haɗa da sassan sanyi na sassan mutuɗar aluminum daga 0.15 lbs. zuwa 6 lbs., saurin canje-canje da aka saita, da aikin inji. Sabis-ƙarin ayyuka sun haɗa da gogewa, faɗakarwa, lalatawa, fashewar harbi, zane, zane, rufi, haɗuwa, da kayan aiki. Abubuwan da aka yi aiki tare sun haɗa da allo irin su 360, 380, 383, da 413.

Zinc ya mutu don jefa ƙirar ƙira / sabis na injiniya tare. Custom manufacturer na daidaici tutiya mutu simintin gyaran kafa. Castananan 'yan simintin gyare-gyare, pressurean ƙwanƙwasa masu juzu'in juzu'in simintin gyare-gyaren juzu'ai, ƙera simintin gyare-gyare na al'ada, ɓangaren mutu da' yan wasa masu mutuwa masu zaman kansu da ƙofar da aka hatimce za a iya ƙera su. Za'a iya kerarrar 'yan simintin a tsayi da faɗi har zuwa 24 a ciki. A cikin +/- 0.0005 a cikin. Haƙuri.

ISO 9001: 2015 bokan masana'anta ta mutu magnesium, Abubuwan haɓaka sun haɗa da matsin lamba na magnesium mai matsi mai yawa har zuwa tan 200 mai ɗumi mai zafi & 3000 ton mai sanyi, ƙirar kayan aiki, gogewa, gyare-gyaren, inji, foda & zanen ruwa, cikakken QA tare da damar CMM , taro, marufi & isarwa.

ITAF16949 bokan. Servicearin Sabis ɗin Gyare Hadawa zuba jari,yashi,Kushin nauyi, Stauren ɓoye ɓoye,Siffar Centrifugal,Cast Vacuum,Dindindin Mould Gyare, .Hanyoyin iyawa sun hada da EDI, taimakon injiniya, ingantaccen samfuri da aiki na sakandare.

Fitar Masana'antu Abubuwan Nazarin sassa don: Motoci, Bikes, Jirgin sama, kayan kiɗa, Jirgin ruwa, Na'urorin hangen nesa, na'urori masu auna sigina, na'urori masu auna sigina, Na'urori, Kayan lantarki, ,unshi, Clocks, Inji, Injiniya, Kayan Kaya, Kayan Jiki, Jigs, Telecom, Haske, Kayan aikin likita, Na'urar daukar hoto, Robobi, Sassaka, kayan sauti, kayan wasanni, Kayan aiki, Kayan wasa da ƙari.

Me Zamu taimake ku yi gaba?

Je zuwa Shafin Farko Don Mutu Wasa China

→Sassan Kasuwanci-Gano abin da muka aikata.

→ Tallan kwankwasiyya Game da Ayyukan Gyare Mutuwa

By Minghe Mutu Wasa Wasa | Categories: Labarai masu Taimakawa |Material Tags: Gyare Aluminum, Zinc Gyare, Fitar Magnesium, Castan Wasanni, Bakin Karfe Cast, Fitar tagulla,Gyare Tagulla,Fitar Bidiyo,Tarihin Kamfanin,Aluminum Mutu Gyare | Comments Off