Tsarin Maganin Zafi Tattaunawar Aluminum-Magnesium Alloy Die-simintin Mould

Amfani da toughening magani da tsarin ƙarfafa aikin farfajiya hanya ce mai mahimmanci don haɓaka aiki da rayuwar ƙirar. Dangane da yanayin aiki da buƙatun aiwatarwa na aluminium-magnesium alloy mutu-simintin mold, wannan labarin yayi nazarin halaye na ƙirar zafi magani da na kowa matakai daki -daki, da kuma nuna cewa m tsari na zafi magani bayani dalla -dalla na iya tabbatar da mold surface taurin, sa juriya, core ƙarfi da tauri, da kuma hana karfe ruwa lalata. Manne da ƙirar na iya rage ƙimar raguwa yadda yakamata kuma yana haɓaka rayuwar sabis na ƙirar.

Aluminum-magnesium alloys ana ƙara amfani da su sosai saboda ƙarancin ƙarancin su da ƙarfin su. Daga cikin su, aluminium-magnesium gami-mutu-simintin fasaha, a matsayin ci gaba na yankan tsari, yana da halaye na babban samarwa yadda ya dace, ceton albarkatun ƙasa, rage ƙimar samarwa, ingantaccen samfur, da babban madaidaici. , An fi amfani da su a cikin kayan lantarki, motoci, motoci, injinan gida da sauran masana'antu, wasu manyan ayyuka, madaidaiciya, ƙwanƙwasawa masu inganci samfuran gami na aluminium-magnesium suma an yi amfani da su ga manyan jiragen sama, jiragen ruwa da sauran masana'antu tare babban buƙatun fasaha.

Yanayin aiki da buƙatun aiwatarwa na aluminium-magnesium alloy die-cast mold

Aluminum-magnesium alloy die-casting mold shine ƙirar mutuƙar da aka yi amfani da ita don yin simintin aluminum-magnesium alloy simintin akan injin mutuƙar simintin. Matsayin narkewa na gami na aluminium shine 600 ~ 750 ℃, kuma wurin narkar da sinadarin magnesium shine 600 ~ 700 ℃. Zazzabi mai aiki yana iya tashi zuwa 500 ~ 600 ℃. Fuskokin ramin, mandrel da bututun ƙarfe duk suna fuskantar sauye -sauyen zafin zafin jiki, kuma fuskar ƙirar tana da sauƙin fashewar gajiya mai zafi. Bugu da ƙari, allurar aluminium-magnesium tana da sauƙin bi a saman farfajiyar yayin aiwatar da mutuƙar, wanda ke shafar ci gaba da aikin mutuƙar simintin. Allurar aluminium-magnesium alloy tana da tasirin gurɓataccen ƙarfi a farfajiyar ƙirar. Saboda haka, don ƙera allurar aluminium-magnesium allo-mutu-simintin gyare-gyare, ana buƙatar ƙirar kayan don samun kwanciyar hankali mai ƙarfi da juriya ga sanyi da gajiya mai zafi a kusan 600 ° C, kuma suna da juriya mai kyau ga babban zafin jiki, babban matsin lamba, babban gudu, da juriya mai yaɗuwa mai ƙarfi na ruwa na aluminium-magnesium. Ƙarfi da taurin ƙirar, kuma a lokaci guda, ana buƙatar madaidaicin maganin zafi don taɓa yuwuwar kayan ƙera da haɓaka rayuwar sabis na ƙirar. A halin yanzu, aluminium-magnesium alloy die-casting die steels a masana'antar kera sun haɗa da: ƙarfe 3Cr2W8V, ƙarfe 4Cr5MoSiV1, ƙarfe 4Cr3Mo3SiV, ƙarfe 4Cr5MoSiV, da sabon nau'in ƙarfe 4Cr5Mo2MnSiV1 karfe da 3Cr3Mo3VNb karfe.

Hanyar sarrafa masana'antu na aluminium-magnesium alloy mutu-simintin mold

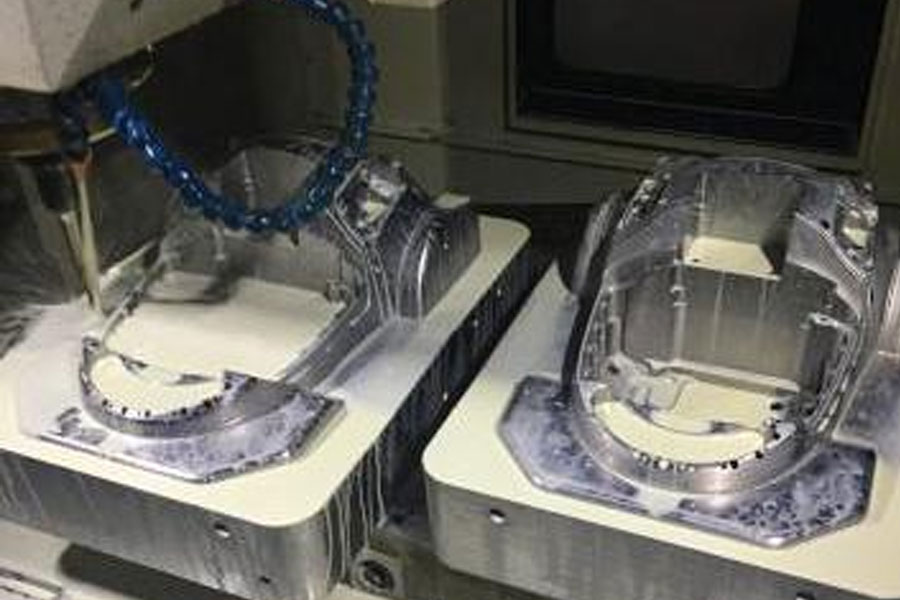

Tsarin masana'anta na aluminium-magnesium alloy mutu-simintin mold shine: blanking, ƙirƙira, spheroidizing annealing → machining en quenching, tempering → gyara, niƙa, goge → nitriding (nitrocarburizing) → taro da amfani.

Ƙarfafa da toughening magani tsari na aluminum-magnesium gami mutu-simintin mold

Maganin toughening na aluminium-magnesium alloy mutu-simintin mold shine canza tsarin ƙarfe don samun tsarin da ake buƙata da aikin ƙirar. Ya kamata maganin zafi ya dogara da kayan kwalliya, sifar sifa, girma, da rikitarwa don ƙayyade ƙayyadaddun tsarin sarrafa zafi.

3.1 Maganin zafin zafi

A pre-zafi magani na mutu-simintin mold iya dauko uku matakai: m annealing, isothermal annealing da quenching da tempering zafi magani. Manufar ita ce samun tsari iri ɗaya da tarwatsa carbide kafin magani na ƙarshe na ƙarshe don haɓaka ƙarfi da taurin karfe. Tsarin ci gaba da ƙonawa yana da sauƙi, kuma ana iya samun ingantaccen tsarin pearlite. Don ƙirar-mutu-siminti tare da sifofi masu rikitarwa da manyan buƙatu, ana iya amfani da ƙoshin isothermal don samun madaidaicin tsarin pearlite.

3.2 Quenching da preheating

Die-simintin mold karfe ne mafi yawa high-gami karfe tare da matalauta thermal watsin. Sau da yawa ana ɗaukar matakan preheating yayin kashewa da dumama. Yawan preheating da zazzabi ya dogara da abun da ke cikin ƙarfe mai mutuƙar da buƙatun don lalata naƙasa. Don ƙirar da ke da ƙarancin zafin zafin jiki, fasali mai sauƙi da ƙarancin buƙatun nakasa, ana buƙatar preheating (800 ~ 850 ℃) yayin kashewa da dumama ba tare da fashewa ba. Don ƙirar da ke kashe zafin zafin jiki mafi girma, sifofi masu rikitarwa da buƙatun naƙasasshe, preheating na biyu (600-650 ° C, 800-850 ° C) ya zama dole. Manufar ita ce rage danniya da aka haifar yayin aikin dumama kuma a lokaci guda yin tsarin gaba ɗaya na kayan kwalliyar.

3.3 Quenching dumama

The quenching dumama zafin jiki na mutu-simintin mold za a iya aiwatar bisa ga quenching dumama jaddadawa na kowane karfe sa. Misali, kashe zafin zafin karfe 3Cr2W8V shine 1050 ~ 1150 ℃, kuma zafin zafin karfe H13 shine 1020 ~ 1100 ℃. Ƙara yawan zafin jiki na baƙin ƙarfe guda biyu na iya ƙara ƙarfin zafin zafin jiki da juriya na gajiya na ƙirar mutuƙar simintin, amma zai ƙara ɓarna na ƙirar. Lokacin dumama a cikin tanderun wanka na gishiri, don gujewa lalata decarburization akan farfajiyar ƙirar, yakamata a yi amfani da wanka mai gishiri na barium chloride tare da deoxidation mai kyau, kuma yakamata a aiwatar da deoxidation akai -akai. Lokacin dumama a cikin tanderu irin na akwatin, yakamata a karɓi yanayin kariya; ko dumama a cikin babban akwati na nau'in juriya na akwati bayan shiryawa. Domin tabbatar da cikakken rushewar carbides, samun austenite mai ɗorewa, da samun kyakkyawan yanayin zafin zafin jiki, ya kamata a ƙara tsawaita lokacin ƙonawa da dumama na ƙirar mutuƙar. Gabaɗaya, ƙarfin riƙewa mai ƙarfi a cikin murhun wanka na gishiri shine 0.8-1.0 min/mm.

3.4 Quench sanyaya

Yawan kashe mai yana da sauri kuma ana iya samun kyakkyawan aiki, amma yanayin nakasa da fasawa yana da kyau. Gabaɗaya, ana amfani da kyawon tsayuwar mai-mutuƙar mai tare da sifofi masu sauƙi da ƙarancin buƙatun nakasa; don m-simintin kyawon tsayuwa tare da sifofi masu rikitarwa da manyan buƙatun nakasa, ya kamata a yi amfani da kashe-kashen matsayi don hana naƙasa da fasawa. Quench sanyaya ya kamata ya zama mai jinkirin da zai yiwu don rage ɓarna naƙasa, dumama da kashewa a cikin tanderun wutar juriya, ana iya ɗaukar sanyaya iskar gas. Dumama da kashewa a cikin wanka mai gishiri, ana iya ɗaukar matakin ƙima a lokacin sanyaya. Lokacin da aka kashe kumburin kuma sanyaya shi, gaba ɗaya ana sanyaya shi zuwa 150 ~ 200 ℃ sannan kuma yayi zafi nan da nan bayan jiƙa. Ba a yarda ya huce zuwa zafin jiki na ɗaki ba.

3.5 Zazzabi

The taurin na mutu-simintin mold aka samu ta tempering, da kuma taurin da mutu-simintin mold rami kai tsaye rinjayar zafi da sanyi gajiya rayuwa na mold. Abubuwa daban -daban, zafin zazzabi daban -daban, da zafin zafin ma daban ne. Misali, taurin 3Cr2W8V karfe aluminium-magnesium alloy mutu-simintin mold gabaɗaya 42 ~ 48HRC, kuma ana zaɓar zafin zafinsa gaba ɗaya tsakanin 560 ~ 620 ℃, amma idan ana amfani da ƙin zafin zafin, zafin zafin yana da girma kamar 670 ℃. Taurin bayan kashe shi a 1150 ° C da zafin jiki a 650 ° C shine 45HRC; yayin da taurin bayan kashewa a 1050 ° C da zafin jiki a 650 ° C shine 35HRC. Taurin H13 karfe aluminum-magnesium alloy die-simintin mold ana buƙatar zama 44 ~ 50HRC. Matsakaicin ƙwanƙwasa na ƙarfe na H13 yana bayyana lokacin zafi a 500 ℃, amma girman ƙwanƙolin yana da alaƙa da zafin zafin. A tempering zafin jiki ne kullum 560 ~ 620 ℃. Dole ne a aiwatar da zafin jiki sau 2 zuwa 3. Zazzabi na farkon zafin jiki na iya zama ƙasa. Bayan zafin zafin farko, auna ƙimar taurin. Idan an isa ga buƙatar taurin, yakamata a saukar da zafin zafin ta 20 ~ 30 ℃ don gujewa Ƙarfin yana raguwa. Idan taurin ya yi yawa, daidaita zafin zafin da ya dace don saduwa da buƙatun taurin gwargwadon babban taurin. Na uku tempering ne don inganta tauri, da tempering zafin jiki ya zama mafi girma fiye da na biyu

Zazzabi na biyu na zafin jiki shine 30 ~ 50 ℃ ƙasa. Lokacin haushi da riƙewa yakamata ya isa ya kawar da damuwar da aka samu yayin kashewa da rage samuwar ɓarna. Lokacin riƙewa ga kowane zafin jiki shine 2h, kuma lokacin riƙewa don manyan kyawon tsayuwa yana dacewa. Dangane da matsanancin danniyar zafi da matsin lamba na microstructure na mutu-simintin mutu bayan an kashe shi, gabaɗaya ana jin zafin mutuwar nan da nan bayan sanyaya zuwa 150-200 ° C.

Surface ƙarfafa magani tsari na aluminum-magnesium gami mutu-simintin mold

Bayan kashewa da haushi, farfajiyar farfajiya ta aluminium-magnesium alloy mutu-simintin mutuƙar ba ta da yawa. Domin samun babban taurin kai da sa juriya akan farfajiyar ƙirar, yayin da babban ɓangaren har yanzu yana riƙe da isasshen ƙarfi da tauri, da haɓaka haɓakar haɓakar ƙirar ƙirar aluminium-magnesium allo-mutu-cast mold, nitriding surface ko nitriding za a iya yi a kan mold. Maganin Carburizing.

4.1 Nitriding magani

Nitriding shine tsarin kula da zafi na nitriding saman ƙarfe don haɓaka haɓakar nitrogen a cikin farfajiyar saman. Manufar nitriding shine rage nakasa sassan sassan, inganta taurin ƙasa, sa juriya, ƙarfin gajiya da juriya na aluminium-magnesium alloy mutu-simintin gyare-gyare, inganta juriya na lalata da keɓaɓɓen yanayi da iska mai zafi, da inganta juriya ga zafin jiki da taushi. Ƙwarewar hankali. M nitriding, nitriding ruwa da nitriding gas sune hanyoyin nitriding na kowa. Sabbin fasahohi irin su nitriding ion, nitriding na injin, nitriding electrolytic da nitriding mai yawa na iya rage gajeriyar nitriding, samun madaidaicin nitriding mai inganci, da haɓaka haɓakar tattalin arziƙi na kamfanoni, don haka ana amfani da su sosai wajen samarwa.

4.2 Nitrocarburizing

Nitrocarburizing shine ammonia tare da abubuwan barasa (methanol, ethanol) da kafofin watsa labarai masu ratsa jiki kamar urea, manne formyl da manne triethanol. Hanyoyin bazuwar zafin jiki yana faruwa a wani zafin jiki don samar da sinadarin nitrogen mai aiki da iskar carbon, wanda allurar aluminium-magnesium ta mutu. Bayan farfajiyar murfin ya mamaye, yana watsawa kuma yana shiga cikin murfin murfin don samun murfin nitrocarburizing na tushen nitrogen, don ƙyallen ya sami mafi girman taurin ƙasa, juriya gajiya, sa juriya da juriya. Hanyoyin nitrocarburizing sun haɗa da hanyoyin ruwa da iskar gas, kuma yawancin hanyoyin da ake amfani da su wajen samar da sinadarin iskar gas. H13 karfe aluminum aluminum mutu-simintin mold yana da zafi a cikin matakai biyu na zafin zafin zafin a 550 × min 40min da 850 × min 40min a cikin tandun wanka mai gishiri mai zafi, an kashe shi a 1030 ℃, mai zafin rai a 600 ℃, sannan aka sanya shi zuwa gas nitrocarburizing zafi zafi a 580 ℃. Taurin yana sama da 900HV, taurin matrix shine 46 ~ 48HRC, juriya mai ƙarfi, juriya gajiya, da juriya na ƙirar ana inganta su sosai, kuma babu adhesion, peeling, scratches da lalata, wanda ke inganta rayuwar rayuwar mold.

Kammalawa

A matsayin kayan aiki mai mahimmanci, aluminium-magnesium alloy mutu-cast molding suna da tasiri kai tsaye akan ingancin samfur da fa'idodin tattalin arziƙin kamfanin. Bincike da kididdiga sun nuna cewa gazawar mold saboda rashin ingantaccen tsarin kula da zafi yana da kusan kashi 50% na duka gazawar. Sabili da haka, zaɓin da ya dace na ƙarfafawa da tsaurara magani da aiwatar da ayyukan ƙarfafa farfajiya na ƙasa da tsananin kula da ƙayyadaddun tsarin sarrafa zafi sune mahimman hanyoyin inganta aikin mold da rayuwa. A cikin samar da allurar aluminium-magnesium allo-mutu-simintin gyare-gyare, ya zama dole don yin nazari da nazarin abubuwan da ke haifar da lalacewar gwargwadon yanayin aiki na kwandon shara, da kuma tsara hanyoyin kula da zafi don tabbatar da ƙyallen farfajiya, sa juriya, ƙarfi da ƙarfi, hana ƙarfe ruwa lalata da mold tsayawar, da kuma yadda ya kamata rage kin amincewa kudi, Mahimmanci inganta rayuwar sabis na mold.

Da fatan za a adana tushe da adireshin wannan labarin don sake bugawa: Tsarin Maganin Zafi Tattaunawar Aluminum-Magnesium Alloy Die-simintin Mould

Minghe Kamfanin 'Yan Wasa Masu Mutu aka sadaukar domin tsirar da samar da inganci da kuma high yi Gyare sassa (karfe mutu simintin sassa Range yafi hada da Thin-Wall Mutu Wasa,Hot Chamber Mutu Wasa,Cold Chamber Mutu Wasa), Zagaye Sabis (Mutuwar 'Yan Wasa,CNC machining,Motsa Motsa, Jiyya na sama) .Adadin al'ada Aluminium ya mutu, magnesium ko Zamak / zinc mutu simintin gyare-gyare da sauran buƙatun simintin maraba don tuntube mu.

Karkashin kulawar ISO9001 da TS 16949, Ana aiwatar da dukkan matakai ta hanyar daruruwan injunan jefa simintin da suka mutu, injunan axis 5, da sauran kayan aiki, tun daga masu fashewa zuwa na’urar Ultra Sonic masu wanki.Minghe ba kawai tana da kayan aiki na zamani ba amma kuma tana da kwararru ƙungiyar ƙwararrun injiniyoyi, masu aiki da sufetoci don tabbatar da ƙirar abokin ciniki ta zama gaskiya.

Manufactureran kwangilar masana'antar mutu. Abubuwan haɓakawa sun haɗa da sassan sanyi na sassan mutuɗar aluminum daga 0.15 lbs. zuwa 6 lbs., saurin canje-canje da aka saita, da aikin inji. Sabis-ƙarin ayyuka sun haɗa da gogewa, faɗakarwa, lalatawa, fashewar harbi, zane, zane, rufi, haɗuwa, da kayan aiki. Abubuwan da aka yi aiki tare sun haɗa da allo irin su 360, 380, 383, da 413.

Zinc ya mutu don jefa ƙirar ƙira / sabis na injiniya tare. Custom manufacturer na daidaici tutiya mutu simintin gyaran kafa. Castananan 'yan simintin gyare-gyare, pressurean ƙwanƙwasa masu juzu'in juzu'in simintin gyare-gyaren juzu'ai, ƙera simintin gyare-gyare na al'ada, ɓangaren mutu da' yan wasa masu mutuwa masu zaman kansu da ƙofar da aka hatimce za a iya ƙera su. Za'a iya kerarrar 'yan simintin a tsayi da faɗi har zuwa 24 a ciki. A cikin +/- 0.0005 a cikin. Haƙuri.

ISO 9001: 2015 bokan masana'anta ta mutu magnesium, Abubuwan haɓaka sun haɗa da matsin lamba na magnesium mai matsi mai yawa har zuwa tan 200 mai ɗumi mai zafi & 3000 ton mai sanyi, ƙirar kayan aiki, gogewa, gyare-gyaren, inji, foda & zanen ruwa, cikakken QA tare da damar CMM , taro, marufi & isarwa.

ITAF16949 bokan. Servicearin Sabis ɗin Gyare Hadawa zuba jari,yashi,Kushin nauyi, Stauren ɓoye ɓoye,Siffar Centrifugal,Cast Vacuum,Dindindin Mould Gyare, .Hanyoyin iyawa sun hada da EDI, taimakon injiniya, ingantaccen samfuri da aiki na sakandare.

Fitar Masana'antu Abubuwan Nazarin sassa don: Motoci, Bikes, Jirgin sama, kayan kiɗa, Jirgin ruwa, Na'urorin hangen nesa, na'urori masu auna sigina, na'urori masu auna sigina, Na'urori, Kayan lantarki, ,unshi, Clocks, Inji, Injiniya, Kayan Kaya, Kayan Jiki, Jigs, Telecom, Haske, Kayan aikin likita, Na'urar daukar hoto, Robobi, Sassaka, kayan sauti, kayan wasanni, Kayan aiki, Kayan wasa da ƙari.

Me Zamu taimake ku yi gaba?

Je zuwa Shafin Farko Don Mutu Wasa China

→Sassan Kasuwanci-Gano abin da muka aikata.

→ Tallan kwankwasiyya Game da Ayyukan Gyare Mutuwa

By Minghe Mutu Wasa Wasa | Categories: Labarai masu Taimakawa |Material Tags: Gyare Aluminum, Zinc Gyare, Fitar Magnesium, Castan Wasanni, Bakin Karfe Cast, Fitar tagulla,Gyare Tagulla,Fitar Bidiyo,Tarihin Kamfanin,Aluminum Mutu Gyare | Comments Off