Yanayin Bincike A Kula da Zafi na Alloys Resistant Resistant Alloys da Superalloys

Ofaya daga cikin mahimman batutuwa don haɓaka 700 ℃ tururi zazzabin A-USC janareta shine haɓaka abubuwan ƙarfe masu tsayayya da zafi don masu ba da injin turbin. Wasu masu bincike sun haɓaka Ni-0.05C-18Cr-13Co-9Mo-1.3Al-1.4Ti-0.1Ta-0.3Nb gami dangane da Inconel 617 a matsayin kayan abu na asali da haɓaka abun da aka haɗa, da gwajin da aka ƙera Babban sikelin ƙirƙira. samfurin impeller wanda ke kwaikwayon impeller na ainihin injin. Akwai rahotannin bincike kan kaddarorin kayan sassa daban -daban na samfurin impeller.

An kimanta madadin kayan aikin da za a iya amfani da su a A-USC janareto tare da zazzabi mai zafi na 700 ℃. Dangane da Ni-0.04C-26Cr-21Co-1Al-1.9Ti-1.8Nb gami, an yi simintin gwajin da aka yi tare da kaurin bango mai matakai 3 kuma an kimanta kayan. Rahoton bincike ya gabatar da tasirin rarrabuwa akan ƙarfin rarrafe.

Ana sa ran superalloy na tushen Ni-Fe zai zama kayan injin turbin don samar da wutar lantarki ta A-USC. Koyaya, don tabbatar da sifofi da ƙera kayan aikin injin turbin, yana da mahimmanci don sarrafa abubuwan ganowa. Har yanzu akwai abubuwa da yawa da ba a sani ba game da tasirin abubuwan ganowa a cikin manyan abubuwan da ke tushen Ni-Fe don masu shigo da injin turbin. Don haka, wasu masu bincike sun bincika tasirin abubuwan da aka gano dangane da halaye masu rarrafe.

A cikin aiwatar da haɓaka 700 ℃ -class A-USC set, don amfani da abubuwa daban-daban masu walƙiya na ƙarfe waɗanda aka haɗa da tushen Ni da Fe a cikin aikace-aikacen, kwanciyar hankali na tsari da kaddarorin injin na walƙiya. an ba da shawara. Da'awa. Wasu masu bincike sun samar da ƙaramin ƙarfe/Inconel 617 waldi kayan azaman ƙirar ƙirar kayan Fe/Ni daban-daban, kuma sun kimanta tasirin tsufa mai zafi akan canjin microstructure na ƙirar walda.

Don rage fitar da hayaki na CO2, an gudanar da bincike mai zurfi kan kayan A-USC. 23Cr-45Ni-7W gami (ASTM UNS N06674) abu ne wanda ke inganta ƙarfin rarrafe ta hanyar ƙarfafa ruwan sama na M23C6 da matakan Laves. Ana iya amfani da shi azaman madadin kayan don bututun tururi mai zafi na A-USC da bututun tukunyar jirgi. Wasu masu bincike sun kimanta tasirin halayen ɓarna na alloy akan halayen hazo na lokacin Laves.

Don haɓaka ƙirar janareta na A-USC tare da zazzabi mai zafi na 700 ℃, yuwuwar amfani da abubuwan da ke jure zafin zafi na Ni kamar yadda aka yi nazarin sassan tukunyar jirgi, kuma an nuna cewa gami 617, wanda shine haɓakar haɓakar hazo. , yana da annashuwa yayin aiwatar da amfani da yanayin zafi mai zafi. Fashewa (fasawar SR) da sauran batutuwa masu alaƙa. A gefe guda, 23Cr-45Ni-7W gami (ASME-CC2684), wanda baya amfani da lokacin a matsayin lokacin ƙarfafa ruwan sama, yana da ƙaramin ƙarfi mai raguwa mai ƙarfi a 700 ° C fiye da na 617 alloy, yayin da 30Cr-50Ni-W gami ba a saukar da shi ba. An ƙarfafa shi, amma ƙarfin ɓarkewar ɓarna ya fi na 23Cr-45Ni-7W gami. Its ductility da SR crack juriya ne mai kyau. Ana iya amfani dashi don babban bututun tururin A-USC. Rahoton bincike ya gabatar da nau'ikan sifofi guda huɗu, kaddarorin injiniya da halayen rarrafe na faranti da manyan bututu masu diamita.

A halin yanzu, matsalar makamashin ta zama lamari mai matukar muhimmanci. Domin inganta ingancin samar da wutar lantarki kamar yadda babban wutar lantarki ke nufi, an gudanar da bincike mai zurfi da ci gaba akan jabu na tushen Ni. Don samun kwanciyar hankali na ƙarfafawa na tushen superalloy na Ni, tsarin lokaci, ba kawai yanayin hazo na lokacin zai sami muhimmiyar tasiri ba, har ma da canjin yanayin halittar da rashin daidaiton lattice tsakaninsa da lokacin iyaye. Yi tasiri mai mahimmanci. Koyaya, bincike akan waɗannan ƙananan gine-ginen galibi bincike ne akan manyan abubuwan da aka yi amfani da su na Ni-Ni tare da babban ƙimar girma na lokaci, yayin da binciken kan abubuwan da aka yi da simintin kaɗan ne. Sabili da haka, wasu rahotannin bincike sun bincika alaƙar da ke tsakanin canjin tsarin lokaci da rashin daidaiton lattice a cikin ƙirar ƙirar Ni.

Da fatan za a adana tushe da adireshin wannan labarin don sake bugawa: Yanayin Bincike A Kula da Zafi na Alloys Resistant Resistant Alloys da Superalloys

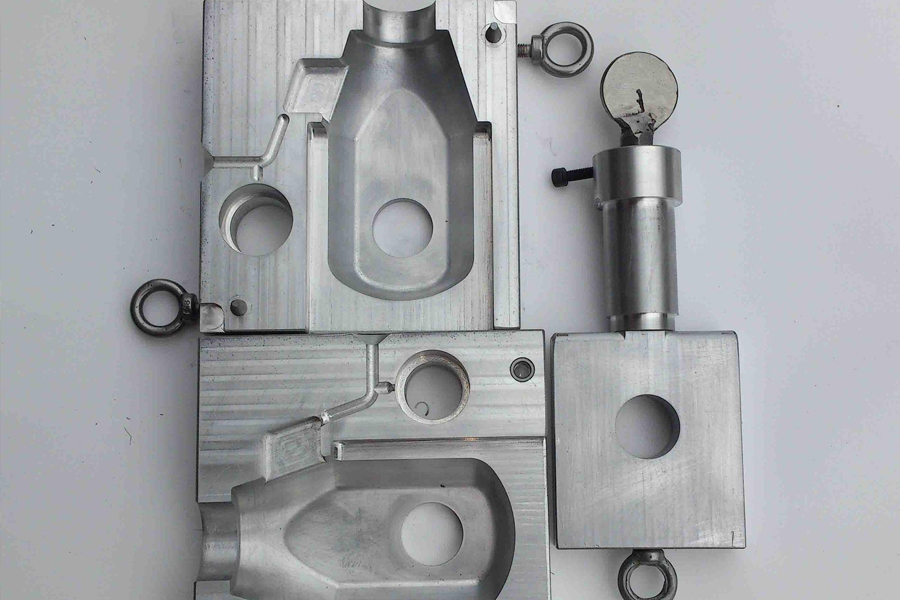

Minghe Kamfanin 'Yan Wasa Masu Mutu aka sadaukar domin tsirar da samar da inganci da kuma high yi Gyare sassa (karfe mutu simintin sassa Range yafi hada da Thin-Wall Mutu Wasa,Hot Chamber Mutu Wasa,Cold Chamber Mutu Wasa), Zagaye Sabis (Mutuwar 'Yan Wasa,CNC machining,Motsa Motsa, Jiyya na sama) .Adadin al'ada Aluminium ya mutu, magnesium ko Zamak / zinc mutu simintin gyare-gyare da sauran buƙatun simintin maraba don tuntube mu.

Karkashin kulawar ISO9001 da TS 16949, Ana aiwatar da dukkan matakai ta hanyar daruruwan injunan jefa simintin da suka mutu, injunan axis 5, da sauran kayan aiki, tun daga masu fashewa zuwa na’urar Ultra Sonic masu wanki.Minghe ba kawai tana da kayan aiki na zamani ba amma kuma tana da kwararru ƙungiyar ƙwararrun injiniyoyi, masu aiki da sufetoci don tabbatar da ƙirar abokin ciniki ta zama gaskiya.

Manufactureran kwangilar masana'antar mutu. Abubuwan haɓakawa sun haɗa da sassan sanyi na sassan mutuɗar aluminum daga 0.15 lbs. zuwa 6 lbs., saurin canje-canje da aka saita, da aikin inji. Sabis-ƙarin ayyuka sun haɗa da gogewa, faɗakarwa, lalatawa, fashewar harbi, zane, zane, rufi, haɗuwa, da kayan aiki. Abubuwan da aka yi aiki tare sun haɗa da allo irin su 360, 380, 383, da 413.

Zinc ya mutu don jefa ƙirar ƙira / sabis na injiniya tare. Custom manufacturer na daidaici tutiya mutu simintin gyaran kafa. Castananan 'yan simintin gyare-gyare, pressurean ƙwanƙwasa masu juzu'in juzu'in simintin gyare-gyaren juzu'ai, ƙera simintin gyare-gyare na al'ada, ɓangaren mutu da' yan wasa masu mutuwa masu zaman kansu da ƙofar da aka hatimce za a iya ƙera su. Za'a iya kerarrar 'yan simintin a tsayi da faɗi har zuwa 24 a ciki. A cikin +/- 0.0005 a cikin. Haƙuri.

ISO 9001: 2015 bokan masana'anta ta mutu magnesium, Abubuwan haɓaka sun haɗa da matsin lamba na magnesium mai matsi mai yawa har zuwa tan 200 mai ɗumi mai zafi & 3000 ton mai sanyi, ƙirar kayan aiki, gogewa, gyare-gyaren, inji, foda & zanen ruwa, cikakken QA tare da damar CMM , taro, marufi & isarwa.

ITAF16949 bokan. Servicearin Sabis ɗin Gyare Hadawa zuba jari,yashi,Kushin nauyi, Stauren ɓoye ɓoye,Siffar Centrifugal,Cast Vacuum,Dindindin Mould Gyare, .Hanyoyin iyawa sun hada da EDI, taimakon injiniya, ingantaccen samfuri da aiki na sakandare.

Fitar Masana'antu Abubuwan Nazarin sassa don: Motoci, Bikes, Jirgin sama, kayan kiɗa, Jirgin ruwa, Na'urorin hangen nesa, na'urori masu auna sigina, na'urori masu auna sigina, Na'urori, Kayan lantarki, ,unshi, Clocks, Inji, Injiniya, Kayan Kaya, Kayan Jiki, Jigs, Telecom, Haske, Kayan aikin likita, Na'urar daukar hoto, Robobi, Sassaka, kayan sauti, kayan wasanni, Kayan aiki, Kayan wasa da ƙari.

Me Zamu taimake ku yi gaba?

Je zuwa Shafin Farko Don Mutu Wasa China

→Sassan Kasuwanci-Gano abin da muka aikata.

→ Tallan kwankwasiyya Game da Ayyukan Gyare Mutuwa

By Minghe Mutu Wasa Wasa | Categories: Labarai masu Taimakawa |Material Tags: Gyare Aluminum, Zinc Gyare, Fitar Magnesium, Castan Wasanni, Bakin Karfe Cast, Fitar tagulla,Gyare Tagulla,Fitar Bidiyo,Tarihin Kamfanin,Aluminum Mutu Gyare | Comments Off