Fasahar Fitar da Matsakaicin Matsala don Allon Alloy Silinda Shugaban Injin Mota na Fasinja

Dangane da cikakken la'akari da farashi da kaddarorin inji, faɗaɗa aikace -aikacen alloy aluminium a halin yanzu shine babban hanyar rage nauyin motocin fasinja da rage amfani da mai. Misali, shugaban silinda injin yanzu an yi shi da aluminium. Kodayake akwai hanyoyin samarwa da yawa don kawunan silinda na aluminium, manyan masana'antun masana'antu sune simintin gyare -gyaren ƙarfe da ƙaramin matsin lamba. Daga cikin su, Turai da China galibi suna amfani da molds na ƙarfe, yayin da Japan da Amurka ke amfani da ƙaramin matsin lamba.

Idan aka kwatanta da simintin gyaran ƙarfe mai nauyi, ƙwanƙwasa ƙwanƙwasawa yana da fa'ida na ingantaccen ƙirar inganci da ƙimar aiwatarwa mai yawa saboda cikawa da ƙarfafawa a ƙarƙashin matsin lamba, amma don simintin kai na silinda tare da sifofi masu rikitarwa da buƙatun babban aiki, akwai matakai masu rikitarwa, Control yana buƙatar m fasaha matsaloli. Sabili da haka, wannan labarin yana mai da hankali kan fasahar simintin ƙaramin matsin lamba na kawunan silinda na aluminium da mahimman mahimman abubuwan sarrafa siginar, don ba da cikakken wasa ga fa'idodin fasaha na tsarin simintin ƙaramin matsin lamba da kuma samar da madaidaicin shugaban silinda. .

Maɓallan maƙasudin ƙaramin matsin lamba na jujjuyawar shugaban silinda

2.1 Misalin tsarin gating

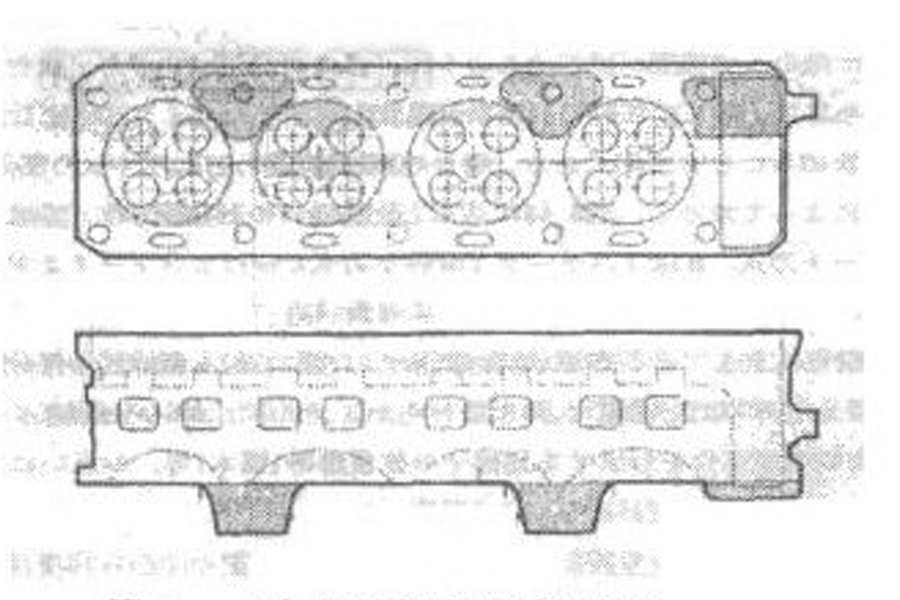

Tsarin aiwatar da simintin ƙaramin matsin lamba na kan silinda yana gaba ɗaya a cikin bututu mai ɗagawa da ƙofofi masu yawa, wanda shine nau'i na rarrabuwa mai ɗimbin yawa. Misali, shugaban silinda mai silinda huɗu yana da tsarin ƙofofin wakilci guda biyu, wato, ƙofofi biyu ko huɗu an saita su a gefen ɗakin konewa. Hoto na 2 tsari ne na tsari na ƙofofi biyu. Wannan tsarin ya dace da ƙirar guda ɗaya ko biyu.

2.2 Abubuwan Alloy da narkewa

Kayan kayan siliki na allurar aluminium gabaɗaya yana zaɓar nau'ikan allo na AI-Si-Cu kamar ZL105 da 107. Idan ana buƙatar tsawaitawa da juriya, ana iya amfani da ZL101 da ZL104. Domin samun ƙarfe mai ƙyalƙyali mai inganci, daidaitaccen aiki yakamata yayi amfani da iskar Ar gas mai jujjuya hurawa da ƙara Sr don gyara da AJ-Ti-B don tace hatsi.

2.3 Tsarin zubarwa

2.3.1 Gyaran Mould

Tsaftacewa ta yau da kullun da kuma kula da ƙyallen yana da matukar mahimmanci don daidaitaccen samar da simintin gyare-gyare na silinda mai inganci da tsawaita rayuwar sabis na ƙirar. Gabaɗaya, yakamata a gudanar da gyaran ƙwayar cuta bayan kowane samfurin 500-700. Babban abun ciki shine a rarrabe kwandon, tsaftace murfin saman rami tare da goga mai taushi, da cire kwakwalwan aluminium da barbashin da ke shiga cikin rata tsakanin sandar ejector da ramin shaye -shaye. , Don tabbatar da ingancin sifar simintin gyaran fuska, fitar da santsi da fitar da hayaƙi.

2.3.2 Rufi

Kafin zubowa, ana yin preheated zuwa kusan 200 ℃ kuma an fesa shi da fenti. Siffar kan silinda yana da rikitarwa, don haka yakamata a biya kulawa ta musamman ga kaurin launi daban -daban a sassa daban -daban. Ana sarrafa kaurin rufin sassan gaba ɗaya tsakanin 0.1 --- 0.2mm: ainihin buƙatun suna da yawa. Misali, farfajiyar dakin konewa yakamata a rufe shi da barbashi mai kyau tare da kaurin O.OSmn. Don ƙofofi, masu hawa, masu tsere na ciki da sauran wurare waɗanda ke buƙatar ƙarfafawa a hankali, yana iya yin kauri, gabaɗaya kusan 0.5-1 mm.

2.3.3 Tace

Manufar sanya matattara shine don hana ƙazantar oxide a cikin bututu mai ɗagawa daga cikin rami da ƙirƙirar cika laminar. Za a iya amfani da rahusa da inganci galvanized karfe raga, da diamita na waya ne .4-0.6mm, 1214 raga.

2.3.4 Zazzabi

Zazzabi na narkakken aluminium yana da babban tasiri akan lahani na ciki na silinda da ingancin bayyanar. Digiri na zubar yakamata ya kasance tsakanin kewayon 680-730, kuma yakamata a sarrafa karkacewar zafin a cikin ainihin aiki a cikin 20 ° C.

Halin simintin ƙaramin matsin lamba shine samun ingantaccen tsari mai ƙarfi. Bayan wannan, yana da mahimmanci a sarrafa zafin jiki na rahoton don zama matsakaici a cikin simintin ƙaramin matsin lamba. An rage rarraba madaidaicin ƙirar ƙirar a hankali daga ƙofar zuwa ƙirar babba, kuma an canza madaidaicin ikon sarrafa kowane bangare don samun. Filin zafin jiki da aka ambata a sama da haɓaka aikin simintin gyare-gyare na silinda da gajartar da sake zagayowar samarwa dole ne a aiwatar da su a kan babba babba da ƙyallen gefe. kwantar da hankali. Gabaɗaya an raba shi zuwa sanyaya ruwa da sanyaya iska, ta amfani da saitunan tashoshi masu yawa, kowane tashar ana sarrafa ta da kansa (gudana da matsa lamba). Ruwan sanyaya ruwa yana amfani da famfon ruwa don ciyar da matsa lamba don magance matsalar ƙarancin ruwan da ke haifar da matsanancin tururi a cikin injin, kuma ana amfani da isasshen iska don sanyaya iska.

Saboda kan Silinda yana da ƙofofi masu yawa, ɗan tazara tsakanin ƙofofin biyu zai haifar da yawan zafin da za a jefa a tsakanin ƙofofi, kuma za a jujjuya tsararren ƙofar da wannan ɓangaren. Sabili da haka, dole ne a saita sanyaya ta tilastawa a cikin wannan ɓangaren don samun madaidaicin zafin jiki da ake buƙata.

Idan aka yi la'akari da rayuwar mold da aminci, sanyaya kai tsaye ya zama babban hanyar sanyaya, kuma ana iya amfani da sanyaya kai tsaye inda kaurin simintin gida ya yi yawa. Akwai hanyoyi guda biyu don sanyaya ƙarfi: sarrafa lokaci da sarrafa zafin jiki. Ikon sarrafa lokaci shine sarrafa lokacin wucewar ruwa ko iska. Wannan hanyar tana da sauƙi kuma mai sauƙin aiwatarwa, amma daidaiton bai yi yawa ba. Ikon zafin jiki shine saita thermocouple a wurin sanyaya, kuma PC ɗin zai kunna ko kashe ruwa mai sanyaya ko iska gwargwadon zafin da ma'aunin zafin jiki ya auna. Daidaitaccen iko yana da inganci.

A cikin 'yan shekarun nan, haɓaka ƙirar ƙirar ƙira mai ƙarfi ta samar da kyakkyawan tunani don inganta tsarin simintin ƙarancin matsin lamba na shugabannin silinda. Zai iya cikakken fahimtar sakamakon gwajin ƙarfafawa a ƙarƙashin yanayi daban -daban, ƙarfafa sarrafa aikin simintin gyare -gyare, da tabbatar da ingancin simintin gyare -gyare.

2.3.5 Lokacin matsawa

Lokaci daga cikawa zuwa ƙarfafa ƙofar ana kiransa lokacin latsawa, wanda zafin jiki ke shafansa ƙwarai. A ƙarƙashin yanayin samar da kwanciyar hankali, kodayake lokacin matsin lamba ya bambanta da nauyin shugaban silinda, ana sarrafa shi gaba ɗaya a 2-8min. Daga hangen nesa na inganta ingancin samarwa, ana iya amfani da hanyoyi kamar ƙirar guda ɗaya, sassa biyu, matsi na mataki biyu, da sauransu don rage lokacin.

2.3.6 Lokacin sakin Mould

Kamar lokacin matsin lamba, yana canzawa saboda canje -canje a zazzabi. Lokacin da lokaci ya yi ƙanƙanta, simintin gyare -gyaren yana da sauƙin lalacewa; lokacin da lokaci ya yi tsawo, simintin gyare -gyare yana da sauƙi a makale a cikin injin kuma ba za a iya fitar da shi ba. Sabili da haka, galibi ana sarrafa shi kusan 1/3 na lokacin matsi. Domin ƙara yawan sanyaya simintin gyare -gyaren, za a iya buɗe ƙirar gefen tare da ƙarancin juriya na saki da farko lokacin da aka zana ƙirar, kuma za a iya buɗe babba na sama bayan sanyaya na wani lokaci.

2.3.7 Matsa lamba

Matsi mai matsin lamba kai tsaye yana shafar aikin cika ruwa da tasirin ciyar da ƙarfe mai narkewa, kuma latsa matsa lamba wani muhimmin sashi ne na sarrafa sarrafa simintin ƙaramin matsin lamba. Ana iya lissafin matsin lamba ta hanyar dabara mai zuwa:

P = γx (1+S/A) x ΔH x 10-2

A cikin dabarar da ke sama, P-matsa lamba (MPa), γ-aluminium madaidaicin nauyi (2.4-2.5), ΔH-aluminium ruwa mai tashi sama (m), S-lif bututu yanki na yanki (m2), A-rami giciye -sakin yanki (m2) o

Matsalar ciyarwar mai hauhawar kusan kusan 0.005-0.01MPa. Kodayake tasirin babban matsin lamba yana da kyau, idan matsin ya wuce 0.01 Mpa, zai sa fenti ya ɓace, ruwan aluminium zai toshe murfin murfin ya shiga cikin yashi. Yana da matukar mahimmanci a fitar da iskar gas da ke haifar da ƙona yashi a cikin lokaci yayin aikin zubarwa, amma saboda yashi da ake amfani da shi a cikin silinda yana da tsari mai rikitarwa kuma mafi girma, yana da wuya a saita adadi mai yawa. na ramukan iska a cikin injin. A wannan lokacin, ƙara matsin lamba na mai ciyarwa zuwa kusa da iyakar babba zai iya hana gas ɗin shiga cikin simintin gyare -gyare.

Canjin matakin ruwa a cikin kogon citrus yana shafar sake maimaita yanayin matsin lamba, don haka matsa lamba a cikin bala'in citrus yakamata a biya diyya ta atomatik. Don simintin gyaran kai na silinda, ana iya saita na'urori masu auna sigina don sarrafa madaidaicin maki sifili I81 na matsin lamba.

Bugu da ƙari, idan tazara tsakanin ƙarshen ƙarshen bututu mai ɗagawa da ƙasan sandar lemu ya yi gajarta, mafita za ta iya haifar da kwararar ruwa cikin sauƙi. Sabili da haka, ba tare da shafar amfani da maganin ba, tazara tsakanin ƙananan ƙarshen bututun riser da kasan tukunyar lemu kusan 200mm.

Gurasar lahani da matakan kariya

Jadawalin 1 ya lissafa lahani na yau da kullun na simintin ƙaramin matsin lamba da matakan da za a ɗauka. Ga sashe mai rikitarwa kamar shugaban silinda, juzu'in sigogi daban -daban na iya shafar ingancin simintin gyaran. Don haka, ya zama dole a yi cikakken bincike da bincike kan fannoni daban -daban kamar tsarin aiwatarwa, ƙirar stencil, tsarin jefawa, da sauransu don fayyace dalilai daban -daban na lahani, da ɗaukar matakan da suka dace akan wannan.

Kammalawa

Zuwa yanzu, kawunan silinda na aluminium suna ɗaya daga cikin 'yan ƙarancin motocin da suka dace da simintin ƙaramin matsin lamba. Sabili da haka, suna ba da cikakken wasa ga fa'idodin babban ƙimar samarwa da kyakkyawan ingancin ciki don faɗaɗa samarwa da aikace-aikacen fasahar simintin gyare-gyare na cikin gida a cikin kawunan silinda na aluminium. Don dacewa da saurin ci gaban fasahar mota ta kasata.

Da fatan za a adana tushe da adireshin wannan labarin don sake bugawa: Fasahar Fitar da Matsakaicin Matsala don Allon Alloy Silinda Shugaban Injin Mota na Fasinja

Minghe Kamfanin 'Yan Wasa Masu Mutu aka sadaukar domin tsirar da samar da inganci da kuma high yi Gyare sassa (karfe mutu simintin sassa Range yafi hada da Thin-Wall Mutu Wasa,Hot Chamber Mutu Wasa,Cold Chamber Mutu Wasa), Zagaye Sabis (Mutuwar 'Yan Wasa,CNC machining,Motsa Motsa, Jiyya na sama) .Adadin al'ada Aluminium ya mutu, magnesium ko Zamak / zinc mutu simintin gyare-gyare da sauran buƙatun simintin maraba don tuntube mu.

Karkashin kulawar ISO9001 da TS 16949, Ana aiwatar da dukkan matakai ta hanyar daruruwan injunan jefa simintin da suka mutu, injunan axis 5, da sauran kayan aiki, tun daga masu fashewa zuwa na’urar Ultra Sonic masu wanki.Minghe ba kawai tana da kayan aiki na zamani ba amma kuma tana da kwararru ƙungiyar ƙwararrun injiniyoyi, masu aiki da sufetoci don tabbatar da ƙirar abokin ciniki ta zama gaskiya.

Manufactureran kwangilar masana'antar mutu. Abubuwan haɓakawa sun haɗa da sassan sanyi na sassan mutuɗar aluminum daga 0.15 lbs. zuwa 6 lbs., saurin canje-canje da aka saita, da aikin inji. Sabis-ƙarin ayyuka sun haɗa da gogewa, faɗakarwa, lalatawa, fashewar harbi, zane, zane, rufi, haɗuwa, da kayan aiki. Abubuwan da aka yi aiki tare sun haɗa da allo irin su 360, 380, 383, da 413.

Zinc ya mutu don jefa ƙirar ƙira / sabis na injiniya tare. Custom manufacturer na daidaici tutiya mutu simintin gyaran kafa. Castananan 'yan simintin gyare-gyare, pressurean ƙwanƙwasa masu juzu'in juzu'in simintin gyare-gyaren juzu'ai, ƙera simintin gyare-gyare na al'ada, ɓangaren mutu da' yan wasa masu mutuwa masu zaman kansu da ƙofar da aka hatimce za a iya ƙera su. Za'a iya kerarrar 'yan simintin a tsayi da faɗi har zuwa 24 a ciki. A cikin +/- 0.0005 a cikin. Haƙuri.

ISO 9001: 2015 bokan masana'anta ta mutu magnesium, Abubuwan haɓaka sun haɗa da matsin lamba na magnesium mai matsi mai yawa har zuwa tan 200 mai ɗumi mai zafi & 3000 ton mai sanyi, ƙirar kayan aiki, gogewa, gyare-gyaren, inji, foda & zanen ruwa, cikakken QA tare da damar CMM , taro, marufi & isarwa.

ITAF16949 bokan. Servicearin Sabis ɗin Gyare Hadawa zuba jari,yashi,Kushin nauyi, Stauren ɓoye ɓoye,Siffar Centrifugal,Cast Vacuum,Dindindin Mould Gyare, .Hanyoyin iyawa sun hada da EDI, taimakon injiniya, ingantaccen samfuri da aiki na sakandare.

Fitar Masana'antu Abubuwan Nazarin sassa don: Motoci, Bikes, Jirgin sama, kayan kiɗa, Jirgin ruwa, Na'urorin hangen nesa, na'urori masu auna sigina, na'urori masu auna sigina, Na'urori, Kayan lantarki, ,unshi, Clocks, Inji, Injiniya, Kayan Kaya, Kayan Jiki, Jigs, Telecom, Haske, Kayan aikin likita, Na'urar daukar hoto, Robobi, Sassaka, kayan sauti, kayan wasanni, Kayan aiki, Kayan wasa da ƙari.

Me Zamu taimake ku yi gaba?

Je zuwa Shafin Farko Don Mutu Wasa China

→Sassan Kasuwanci-Gano abin da muka aikata.

→ Tallan kwankwasiyya Game da Ayyukan Gyare Mutuwa

By Minghe Mutu Wasa Wasa | Categories: Labarai masu Taimakawa |Material Tags: Gyare Aluminum, Zinc Gyare, Fitar Magnesium, Castan Wasanni, Bakin Karfe Cast, Fitar tagulla,Gyare Tagulla,Fitar Bidiyo,Tarihin Kamfanin,Aluminum Mutu Gyare | Comments Off