Matakan Don Inganta Rayuwar Aluminum-Magnesium Alloy Die Casting Mould

A matsayin kayan aiki mai mahimmanci, aluminium-magnesium alloy mutu-cast molding suna da tasiri kai tsaye akan ingancin samfur da fa'idodin tattalin arziƙin kamfanin. Kayan kwalliya da fasahar maganin zafi sune manyan abubuwan da ke shafar rayuwar aluminium-magnesium alloy mutu-cast mold. Wannan labarin yana nazarin manyan hanyoyin gazawar aluminium-magnesium alloy mutu-simintin kyandirori, a taƙaice yana gabatar da ƙirar ƙirar hankula da hanyoyin jiyya na zafi na yau da kullun, kuma yana nuna cewa zaɓi mai dacewa na kayan ƙirar da hanyoyin sarrafa zafi na iya inganta ingantaccen yanayin kwanciyar hankali, ƙarfi , sa juriya, da kwanciyar hankali na zafi. Properties kamar gajiya da yanayin zafi, saboda haka yana ƙaruwa rayuwar sabis na mold.

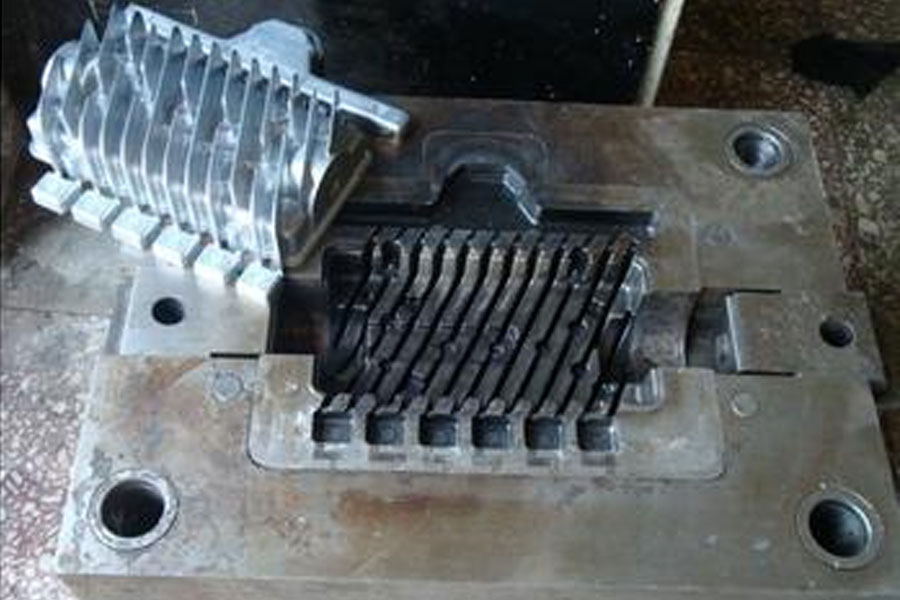

Yanayin Kasawa na Aluminum-Magnesium Alloy Die Casting Mould

Aluminum-magnesium alloy die-simintin mold shine ƙirar ƙirar da aka yi amfani da ita don yin simintin aluminum-magnesium alloy simintin akan injin mutuƙar simintin. A yanayin zafi na rami iya isa game da 600 ℃ a lokacin aiki, da kuma narkakkun aluminum-magnesium gami ruwa ne sauki bi zuwa karfe kayan. Aikace-aikacen aikace-aikace akai-akai na suturar ƙura-ƙulle zuwa rami mai ƙyalƙyali yana haifar da canjin yanayi mai ƙarfi a cikin zafin zafin farfajiyar. Babban hanyoyin rashin nasara shine kwarjini, yashewa, gajiya mai zafi da sawa. Lokacin da tsarin ramin murfin yake da rikitarwa kuma akwai matsin lamba, ƙirar za ta karye kuma ta gaza a ƙarƙashin aikin haɗin kayan zafi da na injin.

1.1 Mould mai tsayi

Lokacin da sassan gami na aluminium-magnesium da farfajiyar ke motsawa, saboda rashin daidaituwa, matsin lambar gida na wasu wuraren tuntuɓar ya zarce ƙarfin ƙarfin kayan don haɗawa, kuma haɗin keɓaɓɓen yana aski da fashewa da ja da baya, yin kayan farfajiyar ƙirar Canja wurin kayan aiki ko faɗi.

1.2 Rushewa

Lokacin farfajiyar ƙirar tana cikin hulɗa tare da ruwa na allurar aluminium-magnesium don motsi na dangi, kumfa da aka kafa a lamba tsakanin ruwa da ƙirar tana fashewa kuma tana haifar da tasiri nan take da zazzabi mai zafi, yana haifar da farfajiyar ƙirar don ƙirƙirar ƙananan ramuka da ramuka. Ruwan allurar aluminium-magnesium da ƙaramin barbashi mai ƙarfi suna faɗuwa cikin babban gudu kuma suna shafar farfajiyar kwatankwacin, yana haifar da asarar kayan gida da kafa ramuka da ramuka a saman ƙarfe. A karkashin mataki na maimaitawa, fasa gajiya zai bunkasa a saman mutuwar, har ma da karayar gida za ta faru.

1.3 Gajiyar Zafi

Ana murƙushe farfajiyar kwandon sau da yawa don dumama da sanyaya don haifar da gajiya da samar da fasa. Babban dalilin fashewar aluminium-magnesium alloy mutu-cast mold shine bambanci tsakanin zazzabin da ke zubowa da zafin zafin zafin na mold. Mafi girman bambancin zafin jiki, da sauri saurin sanyaya, mafi sauƙin ɓarkewar gajiya mai zafi zai faru. Abu na biyu, saurin sake zagayowar zafi, tsarin kula da zafi na injin da kuma Surface treatment shima yana da alaƙa.

1.4 Tufafi

Saboda takaddama tsakanin farfajiyar kwandon da kayan sarrafa kayan zafi na aluminium-magnesium ba za a iya shafawa ba, kuma kayan aikin da ke da zafi suna ƙonewa, farfajiyar murfin yana da taushi da taushi, kuma ƙarancin taurin yana ƙara lalacewa. Babban lalacewa yana hana ƙirar sarrafa samfuran da suka cancanta. Ritaya ba ta da inganci.

1.5 Hutu

Abin al'ajabi da cewa aluminium-magnesium alloy mutu-simintin mold yana da manyan fasa ko rabuwa na ɗan lokaci yayin aiki kuma ya rasa ikon sabis na yau da kullun ana kiransa gazawar karaya. Kullun karaya galibi ana bayyana shi azaman gutsuttsuran gida ko kuma duk ƙirar ta karye zuwa sassa da yawa.

Zaɓin Aluminum Magnesium Alloy Die Casting Die Karfe

Nau'in kayan kwalliya, abun da ke cikin sinadarai, tsarin ƙirar ƙarfe, taurin, tauri, tsarin hypoploid da sauran cikakkun abubuwan sune mahimman dalilan gazawar aluminium-magnesium alloy mutu-cast mold. Yanayin aiki mara kyau yana buƙatar ƙirar aluminium-magnesium allo-mutu-simintin gyare-gyare don samun babban Aiki na kwanciyar hankali mai ɗorewa da juriya ga sanyi da gajiya mai zafi, yana da juriya mai ƙarfi ga babban zafin jiki, babban matsin lamba da madaidaicin ruwa mai ƙarfi na aluminium-magnesium alloy. babban ƙarfi da tauri.

2.1 3Cr2W8V (H21) karfe

Ya ƙunshi ƙarin tungsten, chromium, da abubuwan vanadium, yana da babban ƙarfi, kwanciyar hankali, da ƙarfin zafi. Ya dace da mutu-simintin molds tare da babban ƙarfin iyawa, babban ƙarfin zafi da kwanciyar hankali mai ɗimuwa.

2.2 4Cr5MoSiV1 (H13) karfe

Yana da babban ƙarfi da juriya ga sanyi da gajiya mai zafi, kuma ba mai sauƙi bane don samar da fasa gajiya mai zafi. Ko da raunin gajiya mai zafi ya bayyana, suna da kauri da gajarta, kuma ba su da sauƙin faɗaɗawa. Babu buƙatar yin zafi kafin amfani, kuma ana iya sanyaya shi ta ruwan famfo. Ƙarfin zafi.

2.3 4Cr5Mo2MnSiV1 (Y10) karfe

Ana ƙara molybdenum tare da adadi mai yawa na kusan kashi 2%, wanda aka haɓaka ta abubuwa kamar vanadium da laka don haɓaka kwanciyar hankali na zafi, kuma ana ƙara adadin silicon da manganese don ƙara ƙarfin matrix, tare da kyakkyawan aikin gajiya mai zafi da juriya ga narkakken ƙarfe na ƙarfe.

2.4 Karfe 4Cr5MoSiV (H11)

Yana cikin aikin tungsten zafi mutu karfe. Yana da tauri mai ƙarfi a ƙarƙashin yanayin zafin jiki na matsakaici, kyakkyawan ƙarfin zafi, aikin gajiya mai zafi da wasu juriya. Ana kashe iska kuma ana bi da zafi a ƙarƙashin ƙananan yanayin yanayin zafi. Nakasasshen yana da ƙanƙanta, yanayin samar da sikelin oxide yayin kashe iska kaɗan ne, kuma yana iya tsayayya da lalacewar gurɓataccen aluminum.

2.5 3Cr3Mo3VNb (HM3) Karfe

Wani sabon nau'in ƙarfi mai ƙarfi da taurin ƙarfe na ƙarfe, wanda ke ƙara alamar alama Nb a ƙarƙashin yanayin ƙarancin abun ciki na carbon don haɓaka juriya da ƙarfin ƙarfin zafi, yana da tasiri mai ƙarfi na sakandare na biyu, kuma zai iya shawo kan ƙirar da kyau. zuwa lalacewa ta zafi, gajiya mai zafi, fashewar zafi, da sauransu.

2.6 4Cr3Mo3SiV (H10) Karfe

Yana da mafi girman taurin, juriya mai zafi da sa juriya a zafin zafin aiki na 500 ~ 600 ℃, kuma yana da ƙima mai ƙarfi da ƙarfi mai ƙarfi, ƙarfin juriya da kwanciyar hankali na zafi ya fi ƙarfe H13, tasirin taurin Ƙarfin da raunin raunin ya fi haka na 3Cr2W8V karfe. Lokacin da zafin zafin ya wuce 260 ℃, taurin ƙarfe ya fi na ƙarfe H13. Amfani da kayan ƙarfi mai ƙarfi da tauri abu ne mai mahimmanci don haɓaka aikin aluminium-magnesium alloy mutu-cast molds da tsawaita rayuwar sabis na ƙirar. Misali, wani madaidaiciya ana sarrafa shi kai tsaye ta ƙarfe 3Cr2W8V. Girman φ180x85mm, buƙatar taurin 42 ~ 46HRC, ana iya yin jifa 249 kawai a samarwa da amfani,

900 guda. Daga baya, an yi shi da 4Cr3Mo3SiV, kuma an ƙara rayuwar sabis zuwa guda 1000.000.

Zaɓin Tsarin Maganin Zafi Don Allon Aluminum-Magnesium Alloy Die-simintin Mould

Maganin zafi na aluminium-magnesium alloy mutu-simintin mold shine canza tsarin ƙirar ƙarfe, don ƙirar zata iya samun tsarin da ake buƙata da aiki, kuma yana iya tsawaita rayuwar sabis na ƙirar. Dole ne a ƙaddara ƙayyadaddun tsarin aikin zafi gwargwadon kayan ƙirar, ƙirar ƙirar, girman, da rikitarwa.

3.1 Maganin zafin zafi

A pre-zafi magani na mutu-simintin mold iya dauko uku matakai: m annealing, isothermal annealing da quenching da tempering zafi magani. Manufar ita ce samun tsari iri ɗaya da tarwatsa carbide kafin magani na ƙarshe na ƙarshe don haɓaka ƙarfi da taurin karfe. Tsarin ci gaba da ƙonawa yana da sauƙi, kuma ana iya samun ingantaccen tsarin pearlite. Don ƙirar-mutu-siminti tare da sifofi masu rikitarwa da manyan buƙatu, ana iya amfani da ƙoshin isothermal don samun madaidaicin tsarin pearlite.

3.2 Kashewa da Zafi

Die-simintin mold karfe ne mafi yawa high-gami karfe tare da matalauta thermal watsin. Sau da yawa ana ɗaukar matakan preheating yayin kashewa da dumama. Yawan preheating da zazzabi ya dogara da abun da ke cikin ƙarfe mai mutuƙar da buƙatun don lalata naƙasa. Don ƙirar da ke da ƙarancin zafin zafin jiki, fasali mai sauƙi, da ƙarancin buƙatun nakasa, ya kamata a yi preheating (800 ~ ~ 850 ℃) yayin kashe wutar ba tare da fashewa ba. Don ƙirar da ke kashe zafin zafin jiki mafi girma, sifofi masu rikitarwa da manyan buƙatun nakasa, preheating na biyu (600 zuwa 650 ° C, 800 zuwa 850 ° C) ya zama dole. Manufar ita ce rage danniya da aka haifar yayin aikin dumama kuma a lokaci guda yin tsarin gaba ɗaya na kayan kwalliyar.

3.3 Kashe Dumama

The quenching dumama zafin jiki na mutu-simintin mold za a iya aiwatar bisa ga quenching dumama jaddadawa na kowane karfe sa. Misali, zafin zafin karfe na 3Cr2W8V karfe shine 1050 ~ 1150 ℃, kuma zafin zafin ƙarfe na H13 shine 1020 ~ 1100 ℃. Domin tabbatar da cikakken rushewar carbides, samun austenite mai ɗorewa, da samun kyakkyawan yanayin zafin zafin jiki, ya kamata a ƙara tsawon lokacin kashewa da dumama na ƙirar mutuƙar. Gabaɗaya, ƙarfin riƙewa mai ƙarfi a cikin murhun wanka na gishiri shine 0.8 ~ 1.0min/mm.

3.4 Quenching Kuma Sanyi

Yawan kashe mai yana da sauri kuma ana iya samun kyakkyawan aiki, amma yanayin nakasa da fasawa yana da kyau. Gabaɗaya, ana amfani da sanyaya mai don ƙirar mutuƙar siminti tare da sifofi masu sauƙi da ƙarancin buƙatun nakasa; don m-simintin kyawon tsayuwa tare da sifofi masu rikitarwa da manyan buƙatun nakasa, ya kamata a yi amfani da kashe-kashen matsayi don hana naƙasa da fasawa. Quench sanyaya ya kamata ya zama mai jinkirin da zai yiwu don rage ɓarna naƙasa, dumama da kashewa a cikin tanderun wutar juriya, ana iya ɗaukar sanyaya iskar gas. Dumama da kashewa a cikin wanka mai gishiri, ana iya ɗaukar matakin ƙima a lokacin sanyaya. Lokacin da aka kashe murfin da sanyaya, yakamata a sanyaya shi nan da nan bayan an jiƙa shi kuma an sanyaya shi zuwa 150 ~ 200 ℃, kuma ba a yarda ya yi sanyi zuwa zafin jiki na ɗaki ba.

3.5 Zazzabi

The taurin na mutu-simintin mold samu ta tempering, da kuma taurin da mutu-simintin mold rami kai tsaye rinjayar zafi da sanyi gajiya rayuwa na mold. Abubuwa daban -daban, zafin zazzabi daban -daban, da zafin zafin ma daban ne. Misali, taurin 3Cr2W8V karfe aluminium-magnesium alloy mutu-cast mold gabaɗaya shine 42 ~ 48HRC, kuma galibi ana zaɓar zafin zafinsa tsakanin 560 ~ 620 ℃, amma idan ana amfani da ƙin zafin zafin, zafin zafin yana da girma kamar 670 ℃. Taurin bayan kashe shi a 1150 ° C da zafin jiki a 650 ° C shine 45HRC; yayin da taurin bayan kashewa a 1050 ° C da zafin jiki a 650 ° C shine 35HRC.

3.6 Ƙarfafa Ƙarfafa Jiyya

Bayan an kashe ƙwanƙwasa ƙwanƙwasawa da zafin jiki, taurin saman ba shi da yawa. Domin samun babban taurin kai da sa juriya akan farfajiyar ƙirar mutuƙar simintin, yayin da babban ɓangaren har yanzu yana riƙe da isasshen ƙarfi da tauri, kuma don haɓaka aikin hana jingina na aluminium-magnesium alloy mutu-cast mold, surface nitriding za a iya yi a kan mutu-simintin mold. Ko maganin nitrocarburizing. Amfani da tsauraran magani da ƙarfafa tsarin jiyya na ƙasa hanya ce mai mahimmanci don haɓaka aikin da rayuwar ƙirar. Misali, matsakaicin zafin zafin nitrocarburizing na H13 mutu-cast mold shine ammonia gas + ethanol, kuma tsarin shine 580 ℃ x4.5h. Bayan kashewa a 1030 ° C da zafin jiki a 600 ° C da 580 gas nitrocarburizing zafi magani, farfajiyar taƙarar tana sama da 900HV, taurin matrix shine 46 ~ 48HRC, da juriya, gajiya juriya da juriya na lalata an inganta su sosai. .

Kammalawa

A cikin samar da aluminium-magnesium alloy mutu-simintin kyandirori, ya zama dole don yin nazari da nazarin abubuwan da ke haifar da gazawa gwargwadon yanayin aiki na ƙirar, zaɓi madaidaicin kayan ƙira, da tsara tsarin kula da zafi mai dacewa don tabbatar da ƙirar surface taurin, sa juriya, core ƙarfi da tauri, da kuma hana karfe ruwa lalata da mold manne. , Yadda yakamata rage ƙin ƙin yarda kuma yana haɓaka rayuwar sabis na ƙira sosai. Aikin samarwa ya tabbatar da cewa preheating aluminium-magnesium alloy mutu-simintin mold zuwa ingantaccen inganci da yanayin tattalin arziƙi na iya rage bambancin zafin jiki tsakanin ƙirar da kayan aikin, rage ƙirar fasa, ƙara tsawon sabis na ƙirar, da haɓaka yawan aiki. Tabbas, yayin amfani da kyandirori na aluminium-magnesium allo-mutu simintin gyare-gyare, yin amfani daidai, gudanarwa mai dacewa, da kulawa mai kyau suma ingantattun matakai ne don rage ɓarkewar ɓarkewar farkon ƙirar da haɓaka rayuwar sabis.

Shafuka masu Alaƙa:masana'antu

Da fatan za a adana tushe da adireshin wannan labarin don sake bugawa: Matakan Don Inganta Rayuwar Aluminum-Magnesium Alloy Die Casting Mould

Minghe Kamfanin 'Yan Wasa Masu Mutu aka sadaukar domin tsirar da samar da inganci da kuma high yi Gyare sassa (karfe mutu simintin sassa Range yafi hada da Thin-Wall Mutu Wasa,Hot Chamber Mutu Wasa,Cold Chamber Mutu Wasa), Zagaye Sabis (Mutuwar 'Yan Wasa,CNC machining,Motsa Motsa, Jiyya na sama) .Adadin al'ada Aluminium ya mutu, magnesium ko Zamak / zinc mutu simintin gyare-gyare da sauran buƙatun simintin maraba don tuntube mu.

Karkashin kulawar ISO9001 da TS 16949, Ana aiwatar da dukkan matakai ta hanyar daruruwan injunan jefa simintin da suka mutu, injunan axis 5, da sauran kayan aiki, tun daga masu fashewa zuwa na’urar Ultra Sonic masu wanki.Minghe ba kawai tana da kayan aiki na zamani ba amma kuma tana da kwararru ƙungiyar ƙwararrun injiniyoyi, masu aiki da sufetoci don tabbatar da ƙirar abokin ciniki ta zama gaskiya.

Manufactureran kwangilar masana'antar mutu. Abubuwan haɓakawa sun haɗa da sassan sanyi na sassan mutuɗar aluminum daga 0.15 lbs. zuwa 6 lbs., saurin canje-canje da aka saita, da aikin inji. Sabis-ƙarin ayyuka sun haɗa da gogewa, faɗakarwa, lalatawa, fashewar harbi, zane, zane, rufi, haɗuwa, da kayan aiki. Abubuwan da aka yi aiki tare sun haɗa da allo irin su 360, 380, 383, da 413.

Zinc ya mutu don jefa ƙirar ƙira / sabis na injiniya tare. Custom manufacturer na daidaici tutiya mutu simintin gyaran kafa. Castananan 'yan simintin gyare-gyare, pressurean ƙwanƙwasa masu juzu'in juzu'in simintin gyare-gyaren juzu'ai, ƙera simintin gyare-gyare na al'ada, ɓangaren mutu da' yan wasa masu mutuwa masu zaman kansu da ƙofar da aka hatimce za a iya ƙera su. Za'a iya kerarrar 'yan simintin a tsayi da faɗi har zuwa 24 a ciki. A cikin +/- 0.0005 a cikin. Haƙuri.

ISO 9001: 2015 bokan masana'anta ta mutu magnesium, Abubuwan haɓaka sun haɗa da matsin lamba na magnesium mai matsi mai yawa har zuwa tan 200 mai ɗumi mai zafi & 3000 ton mai sanyi, ƙirar kayan aiki, gogewa, gyare-gyaren, inji, foda & zanen ruwa, cikakken QA tare da damar CMM , taro, marufi & isarwa.

ITAF16949 bokan. Servicearin Sabis ɗin Gyare Hadawa zuba jari,yashi,Kushin nauyi, Stauren ɓoye ɓoye,Siffar Centrifugal,Cast Vacuum,Dindindin Mould Gyare, .Hanyoyin iyawa sun hada da EDI, taimakon injiniya, ingantaccen samfuri da aiki na sakandare.

Fitar Masana'antu Abubuwan Nazarin sassa don: Motoci, Bikes, Jirgin sama, kayan kiɗa, Jirgin ruwa, Na'urorin hangen nesa, na'urori masu auna sigina, na'urori masu auna sigina, Na'urori, Kayan lantarki, ,unshi, Clocks, Inji, Injiniya, Kayan Kaya, Kayan Jiki, Jigs, Telecom, Haske, Kayan aikin likita, Na'urar daukar hoto, Robobi, Sassaka, kayan sauti, kayan wasanni, Kayan aiki, Kayan wasa da ƙari.

Me Zamu taimake ku yi gaba?

Je zuwa Shafin Farko Don Mutu Wasa China

→Sassan Kasuwanci-Gano abin da muka aikata.

→ Tallan kwankwasiyya Game da Ayyukan Gyare Mutuwa

By Minghe Mutu Wasa Wasa | Categories: Labarai masu Taimakawa |Material Tags: Gyare Aluminum, Zinc Gyare, Fitar Magnesium, Castan Wasanni, Bakin Karfe Cast, Fitar tagulla,Gyare Tagulla,Fitar Bidiyo,Tarihin Kamfanin,Aluminum Mutu Gyare | Comments Off