Yadda za a inganta matakan aiwatar da simintin gyare-gyare na saurin spheroidization

Ana buƙatar matakin spheroidization na simintin gyare -gyaren simintin ƙarfe na cikin gida don isa matakin 4 ko sama, (wato, ƙimar spheroidization shine 70%), ƙimar spheroidization da babban kamfani ya samu kusan 85%. A cikin 'yan shekarun nan, tare da haɓaka samar da baƙin ƙarfe na nodular, musamman a masana'antun da ke da manyan buƙatun don samar da wutar iska da ingancin simintin gyare -gyare, ana buƙatar matakin spheroidization don isa matakin 2, wato ƙimar spheroidization ya kai sama da 90%. Kamfanin marubucin yayi nazari tare da inganta tsarin spheroidization da tsarin inoculation da aka yi amfani da su a cikin QT400-15, kazalika da wakili mai cutarwa da inoculant, don ƙimar spheroidization na nodular simintin ƙarfe ya kai sama da 90%.

1. Tsarin samar da asali

Tsarin samarwa na asali:

- Kayan aikin narkewa yana ɗaukar 2.0T matsakaicin tanderu da wutar lantarki ta mita 1.5T;

- Haɗin QT400-15 danyen baƙin ƙarfe shine ω (C) = 3.75%~ 3.95%, ω (Si) = 1.4%~ 1.7%, ω (Mn) ≤0.40%, ω (P) ≤0.07%, ω ( S)) ≤0.035%;

- Wakilin da ake amfani da shi a cikin maganin warkarwa shine 1.3% zuwa 1.5% RE3Mg8SiFe gami;

- Inoculant da ake amfani da shi a cikin maganin allurar shine 0.7% ~ 0.9% 75SiFe-C gami. Magungunan spheroidizing yana ɗaukar hanyoyi biyu na taɓo da ruwa:

Da farko, 55% ~ 60% na baƙin ƙarfe ana samarwa, sannan ana aiwatar da spheroidizing, sannan ana ƙara inoculant, sannan ana ƙara sauran ruwan ƙarfe.

Dangane da hanyar gargajiya na spheroidization da inoculation, ƙimar spheroidization da aka gano ta toshe guda ɗaya na gwajin gwaji tare da kaurin 25 mm gabaɗaya kusan kashi 80%, wato matakin spheroidization shine na 3.

2. Tsarin gwaji don inganta ƙimar spheroidization

Don haɓaka ƙimar spheroidization, an inganta asalin tsarin warkarwa da inoculation. Manyan matakan sune: ƙara adadin wakili mai cutarwa da inoculant, tsarkake narkakken baƙin ƙarfe, da warkar da ruwa. Har yanzu ana gwada ƙimar spheroidization tare da shinge na gwaji guda ɗaya na 25 mm. Tsarin musamman shine kamar haka:

- (1) Yi nazarin dalilin ƙarancin ƙarancin spheroidization na tsarin asali. An yi tunanin cewa adadin wakili na ƙaramin abu ne, don haka an ƙara adadin wakilin da aka ƙara daga 1.3% zuwa 1.4% zuwa 1.7%, amma ƙimar spheroidizing bai cika buƙatun ba. . (2) Wani zato shine cewa ƙimar ƙarancin spheroidization na iya haifar da ƙarancin ciki ko raguwar haihuwa. Sabili da haka, gwajin ya haɓaka adadin inoculation daga 0.7% zuwa 0.9% zuwa 1.1%, kuma ƙimar spheroidization bai cika buƙatun ba.

- (3) Ci gaba da yin bincike kuma yi imani cewa akwai ƙarin abubuwan haɗawa a cikin narkakken baƙin ƙarfe da manyan abubuwan kutse na spheroidization na iya zama sanadin ƙarancin ƙimar spheroidization. Sabili da haka, ana aiwatar da tsarkakewar zafin zafin baƙin ƙarfe. Ana sarrafa yawan zafin tsarkakewa mai tsananin zafi a 1500 ± 10 ° C, amma ƙimar sa ba ta wuce 90%ba.

- (4) Babban adadin ω (S) da gaske yana cinye ƙwayar spheroidizing kuma yana hanzarta raguwar spheroidization. Sabili da haka, ana ƙaruwa da maganin desulfurization don rage adadin ruwan iron (S) na ƙarfe na asali daga 0.035%zuwa ƙasa da 0.020%, amma ƙimar spheroidization shima ya kai 86%. An nuna sakamakon gwajin makirci huɗu da ke sama a cikin Table 1. Tsarin da kaddarorin inji na shingen gwajin siffa mai ɗanɗano bai cika buƙatun ba.

3. An inganta shirin ingantawa na ƙarshe

3.1 Matakan haɓaka na musamman

- Kayan albarkatun ƙasa sune ƙarfe alade, m ko ƙarancin tsattsarkan tsatsa da kayan reheating;

- Desulfurization of raw molten iron by add soda ash (Na2CO3) a cikin tanderun;

- Yi amfani da wakili na Foseco 390 don pre-deoxidize a cikin jaka;

- Yin maganin wariyar launin fata tare da Fozco Nodulizer;

- Amfani da silicon carbide da ferrosilicon haɗe inoculation.

Ikon sarrafa madaidaicin ƙarfe na sabon tsarin: ω (C) = (3.70% ~ 3.90%, ω (Si) = 0.80% ~ 1.20% [simintin ω (Si na ƙarshe) = 2.60% ~ 3.00%], ω ( Mn) ≤ 0.30%, ω (P) ≤0.05%, ω (S) ≤0.02%. Lokacin da baƙin ƙarfe na ƙarfe ω (S) ya wuce 0.02%, ana amfani da tokar soda ta masana'antu don lalata ruwa a gaban tanderun, saboda Maganin desulfurization shine maganin endothermic, Ana buƙatar zafin zafin desulfurization a kusan 1500 ° C, kuma ana sarrafa adadin soda ash wanda aka sarrafa a 1.5% ~ 2.5% gwargwadon adadin ω (S) yayin narkewa a cikin tanderun .

A lokaci guda, fakitin jiyya yana ɗaukar fakitin magani na nau'in dam. Na farko, ƙara 1.7% na Foseco NODALLOY7RE wakilin spheroidizing wakili a gefen dam ɗin a ƙarshen fakitin, shimfidawa da ƙarami, kuma amfani da carbide na silicon na 0.2% da ƙananan 0.3% Ƙananan 75SiFe an rufe shi da ɗaya Layer ɗaya bayan ɗaya , kuma bayan tamping, an rufe shi da baƙin ƙarfe na matsa lamba, kuma 0.3% Foseke 390 inoculant an ƙara shi zuwa ɗayan gefen narkakken baƙin ƙarfe. Lokacin bugun ƙarfe, 55% ~ 60% na jimlar ƙarar baƙin ƙarfe da farko an fara zubar da shi. Bayan an gama aikin ɓarna, an ƙara 1.2% 75SiFe-C inoculant kuma sauran narkakken baƙin ƙarfe ya bushe, kuma an zub da slag.

3.2 Sakamakon gwaji

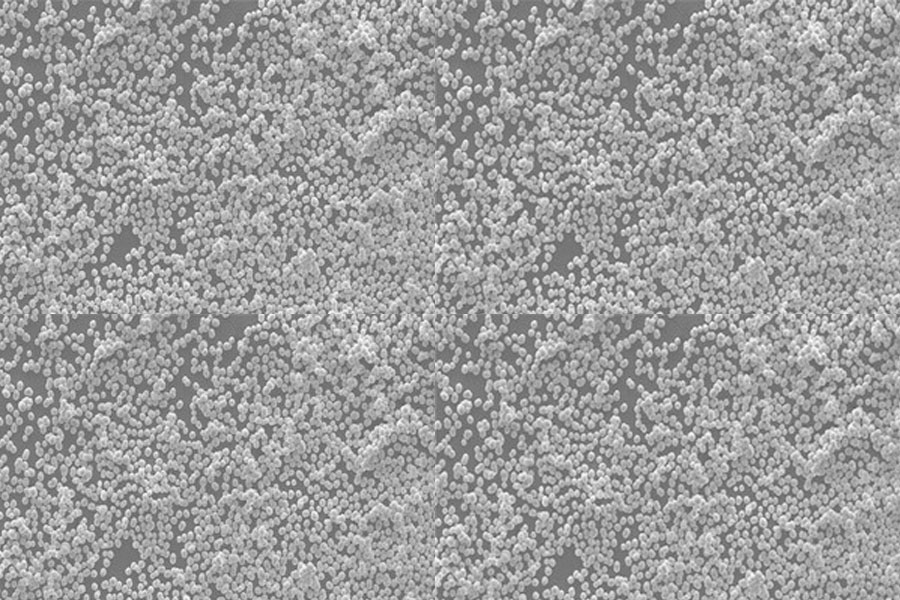

Abun da aka ƙera na ƙarfe na asali kafin da bayan lalatawa, kaddarorin injiniya da tsarin ƙarfe na shinge na sifar sifar sifar 25mm guda ɗaya, da hanyar kimanta ƙimar spheroidization a cikin tsarin ƙirar ƙarfe ana gano su ta atomatik ta tsarin nazarin hoto na ƙarfe. .

4. Sakamakon sakamako

4.1 Tasirin manyan abubuwa akan ƙimar spheroidization

- C, Si: C na iya haɓaka zane -zane da rage ɗabi'ar farin baki, amma babban adadin ω (C) zai sa CE ta yi yawa kuma cikin sauƙi zai sa graphite ya yi iyo, galibi ana sarrafa shi a 3.7%~ 3.9%. Si na iya ƙarfafa ikon tsara hoto da kawar da siminti. Lokacin da aka ƙara Si a matsayin mai inoculant, zai iya rage ƙarfin supercooling na narkakken ƙarfe.Domin inganta tasirin inoculation, an rage adadin ω (Si) a cikin baƙin ƙarfe na asali daga 1.3% zuwa 1.5% zuwa 0.8% zuwa 1.2%, kuma adadin ω (Si na ƙarshe) an sarrafa shi a 2.60%zuwa 3.00%.

- Mn: A yayin aiwatar da crystallization, Mn yana haɓaka yanayin ƙarfe ƙarfe zuwa overcool kuma yana haɓaka samuwar carbides (FeMn) 3C. A cikin tsarin canji na eutectoid, Mn yana rage zafin canjin eutectoid, yana daidaitawa da tsaftace pearlite. Mn ba shi da tasiri sosai akan ƙimar spheroidization. Saboda tasirin albarkatun ƙasa, gaba ɗaya sarrafa ω (Mn) <0.30%.

- P: Lokacin ω (P) <0.05%, yana da ƙarfi-mai narkewa a cikin Fe, kuma yana da wahala a samar da phosphorus eutectic, wanda ba shi da tasiri a kan ƙimar spheroidization na baƙin ƙarfe.

- S: S wani abu ne mai rarrabewa. S yana cinye Mg da RE a cikin wakilin spheroidizing yayin halayen spheroidizing, yana hana haɓaka hoto da rage ƙimar spheroidizing. Sulfide slag kuma zai koma ga sulfur kafin narkakken ƙarfe ya ƙarfafawa, ya sake cinye abubuwan ɓarna, ya hanzarta raguwar spheroidization, kuma ya ƙara rinjayar ƙimar spheroidizing. Don cimma babban adadin spheroidization, adadin ω (S) a cikin baƙin ƙarfe ya kamata a rage zuwa ƙasa da 0.02%.

4.2 Desulfurization magani

Bayan an narkar da cajin, ɗauki samfura kuma bincika abubuwan sunadarai. Lokacin da adadin ω (S) ya fi 0.02%, ana buƙatar lalata abubuwa.

Ka'idar soda ash desulfurization shine: sanya wani adadin soda ash a cikin ladle, yi amfani da narkakken ƙarfe don kwarara da motsawa, tokar soda ta lalace a babban zafin jiki, dabarar amsa ita ce Na2CO3 = Na2O+CO2 ↑: Na2O da aka samar shine a cikin narkakken baƙin ƙarfe kuma Sulfuration da samuwar Na2S, (Na2O) + [FeS] = (Na2S) + (FeO).

Na2CO3 ya ware kuma ya warware CO2, yana haifar da tashin hankali na narkakkar baƙin ƙarfe, wanda ke inganta tsarin lalata abubuwa. Soda ash slag yana da sauƙin kwarara da taso kan ruwa da sauri, kuma lokacin ɗaukar desulfurization ya takaice sosai. Bayan desulfurization, yakamata a cire slag cikin lokaci, in ba haka ba zai koma sulfur. 4.3 Maganin pre-deoxidation, maganin warkar da warkarwa da maganin inoculation Foseke 390 wakilin sa-ido yana taka rawar maganin pre-deoxidation a cikin jaka, kuma a lokaci guda yana haɓaka ginshiƙan ginshiƙan ginshiƙi da adadin ginshiƙan ginshiƙi a kowane yanki, kuma yana iya ƙara yawan sha na Mg. Yana da mahimmanci haɓaka ikon yin tsayayya da koma bayan tattalin arziki da haɓaka ƙimar spheroidization. Fochke inoculant ya ƙunshi ω (Si) = 60% ~ 70%, ω (Ca) = 0.4% ~ 2.0%, ω (Ba) = 7% ~ 11%, wanda Ba zai iya tsawaita ingantaccen lokacin shiryawa. An zaɓi darajar NODALLOY7RE na Fozco Nodulizer, kuma ω (Si) = 40%~ 50%, ω (Mg) = 7.0%~ 8.0%, ω (RE) = 0.3%~ 1.0%, ω (Ca) = 1.5 %~ 2.5%, ω (Al) <1.0%. Tun da narkakken baƙin ƙarfe yana shan desulfurization da pre-deoxidation jiyya, abubuwan da ke cinye nodulizer a cikin narkakken ƙarfe suna raguwa sosai, don haka an zaɓi nodulizer tare da ƙarancin ω (RE) don rage lalacewar ilimin halittar spheroidal graphite morphology ta RE ; Babban jigon aikin shine Mg; Ca da Al na iya taka rawa wajen ƙarfafa shiryawa. Yin amfani da carbide silicon da ferrosilicon haɗe da allurar inoculation, wurin narkar da silicon carbide kusan 1600 ° C, kuma ƙirar girasar giraf tana ƙaruwa yayin ƙarfafawa, kuma ana amfani da manyan allurai na ferrosilicon don allurar rigakafi, wanda zai iya hana spheroidization daga raguwa.

Kammalallen 5

A cikin samar da baƙin ƙarfe nodular simintin ƙarfe, lokacin da ake buƙatar ƙimar spheroidization ya kai sama da 90%, ana iya ɗaukar matakan masu zuwa:

- (1) Zaɓi cajin inganci don rage abubuwan ɓarna a cikin cajin.

- (2) Zaɓi wakilin spheroidizing tare da ƙaramin adadin ω (RE) don rage lalacewar tasirin RE akan ilimin halittar spheroidal graphite.

- (3) Abun cikin ω (S) na baƙin ƙarfe na asali yakamata ya zama ƙasa da 0.020%, wanda zai iya rage yawan amfani da abubuwan nodulizer, musamman abubuwan da ba a cika yin amfani da su ba ta amfani da sulfurization na biyu na slag sulfide.

- (4) Pre-deoxidize narkakken baƙin ƙarfe, ƙara adadin ginshiƙan ginshiƙai a kowane yanki naúra, haɓaka ƙimar spheroidization, inganta ƙimar ƙarfin tsayayya da koma bayan tattalin arziki, da kuma tsawaita lokacin shiryawa mai inganci.

- (5) Rage adadin ω (Si) a cikin baƙin ƙarfe na asali, ƙara adadin wakilin spheroidizing, inoculant da wakilan rigakafin daban -daban, da ƙarfafa maganin allurar.

Da fatan za a adana tushe da adireshin wannan labarin don sake bugawa: Yadda za a inganta matakan aiwatar da simintin gyare-gyare na saurin spheroidization

Minghe Kamfanin 'Yan Wasa Masu Mutu aka sadaukar domin tsirar da samar da inganci da kuma high yi Gyare sassa (karfe mutu simintin sassa Range yafi hada da Thin-Wall Mutu Wasa,Hot Chamber Mutu Wasa,Cold Chamber Mutu Wasa), Zagaye Sabis (Mutuwar 'Yan Wasa,CNC machining,Motsa Motsa, Jiyya na sama) .Adadin al'ada Aluminium ya mutu, magnesium ko Zamak / zinc mutu simintin gyare-gyare da sauran buƙatun simintin maraba don tuntube mu.

Karkashin kulawar ISO9001 da TS 16949, Ana aiwatar da dukkan matakai ta hanyar daruruwan injunan jefa simintin da suka mutu, injunan axis 5, da sauran kayan aiki, tun daga masu fashewa zuwa na’urar Ultra Sonic masu wanki.Minghe ba kawai tana da kayan aiki na zamani ba amma kuma tana da kwararru ƙungiyar ƙwararrun injiniyoyi, masu aiki da sufetoci don tabbatar da ƙirar abokin ciniki ta zama gaskiya.

Manufactureran kwangilar masana'antar mutu. Abubuwan haɓakawa sun haɗa da sassan sanyi na sassan mutuɗar aluminum daga 0.15 lbs. zuwa 6 lbs., saurin canje-canje da aka saita, da aikin inji. Sabis-ƙarin ayyuka sun haɗa da gogewa, faɗakarwa, lalatawa, fashewar harbi, zane, zane, rufi, haɗuwa, da kayan aiki. Abubuwan da aka yi aiki tare sun haɗa da allo irin su 360, 380, 383, da 413.

Zinc ya mutu don jefa ƙirar ƙira / sabis na injiniya tare. Custom manufacturer na daidaici tutiya mutu simintin gyaran kafa. Castananan 'yan simintin gyare-gyare, pressurean ƙwanƙwasa masu juzu'in juzu'in simintin gyare-gyaren juzu'ai, ƙera simintin gyare-gyare na al'ada, ɓangaren mutu da' yan wasa masu mutuwa masu zaman kansu da ƙofar da aka hatimce za a iya ƙera su. Za'a iya kerarrar 'yan simintin a tsayi da faɗi har zuwa 24 a ciki. A cikin +/- 0.0005 a cikin. Haƙuri.

ISO 9001: 2015 bokan masana'anta ta mutu magnesium, Abubuwan haɓaka sun haɗa da matsin lamba na magnesium mai matsi mai yawa har zuwa tan 200 mai ɗumi mai zafi & 3000 ton mai sanyi, ƙirar kayan aiki, gogewa, gyare-gyaren, inji, foda & zanen ruwa, cikakken QA tare da damar CMM , taro, marufi & isarwa.

ITAF16949 bokan. Servicearin Sabis ɗin Gyare Hadawa zuba jari,yashi,Kushin nauyi, Stauren ɓoye ɓoye,Siffar Centrifugal,Cast Vacuum,Dindindin Mould Gyare, .Hanyoyin iyawa sun hada da EDI, taimakon injiniya, ingantaccen samfuri da aiki na sakandare.

Fitar Masana'antu Abubuwan Nazarin sassa don: Motoci, Bikes, Jirgin sama, kayan kiɗa, Jirgin ruwa, Na'urorin hangen nesa, na'urori masu auna sigina, na'urori masu auna sigina, Na'urori, Kayan lantarki, ,unshi, Clocks, Inji, Injiniya, Kayan Kaya, Kayan Jiki, Jigs, Telecom, Haske, Kayan aikin likita, Na'urar daukar hoto, Robobi, Sassaka, kayan sauti, kayan wasanni, Kayan aiki, Kayan wasa da ƙari.

Me Zamu taimake ku yi gaba?

Je zuwa Shafin Farko Don Mutu Wasa China

→Sassan Kasuwanci-Gano abin da muka aikata.

→ Tallan kwankwasiyya Game da Ayyukan Gyare Mutuwa

By Minghe Mutu Wasa Wasa | Categories: Labarai masu Taimakawa |Material Tags: Gyare Aluminum, Zinc Gyare, Fitar Magnesium, Castan Wasanni, Bakin Karfe Cast, Fitar tagulla,Gyare Tagulla,Fitar Bidiyo,Tarihin Kamfanin,Aluminum Mutu Gyare | Comments Off