Tattaunawar Fasahar Maɓallin Fitar Aluminum Alloy

Siffar Allon Alloy Shell Castings

Aluminum gami harsashi simintin ana amfani da su a cikin zamani mota masana'antu. Saboda sifofin su na yau da kullun, yana da wahala ga wasu tsarukan su cika ƙa'idodin inganci ta hanyar sarrafa injin. Sabili da haka, ana amfani da wasu simintin ƙarfe na aluminium kawai don ƙirar shimfidar harsashi na mota. Daga hangen zaman lafiyar amfani da motoci, masana'antar tana da buƙatun inganci masu tsauri don simintin aluminum. Duk simintin gyare -gyare suna da tsauraran ƙa'idodi don ƙarfin kayan. A cikin buƙatun simintin gyare -gyare, farfajiya, Matsayi biyu don ingancin ciki. Don tabbatar da ingancin samfur, wasu masana'antun sun karɓi fasahar gano ɓoyayyen ɓoyayyen don sarrafa duk tsarin samarwa.

| Halayen Inji | Grade |

| Ƙarfin ƙarfi Mpa (min) | 240 |

| Ƙarfin ƙarfi Mpa (min) | 140 |

| Tsawaitawa %(min) | <1 |

| Brinell taurin HB (min) | 80 |

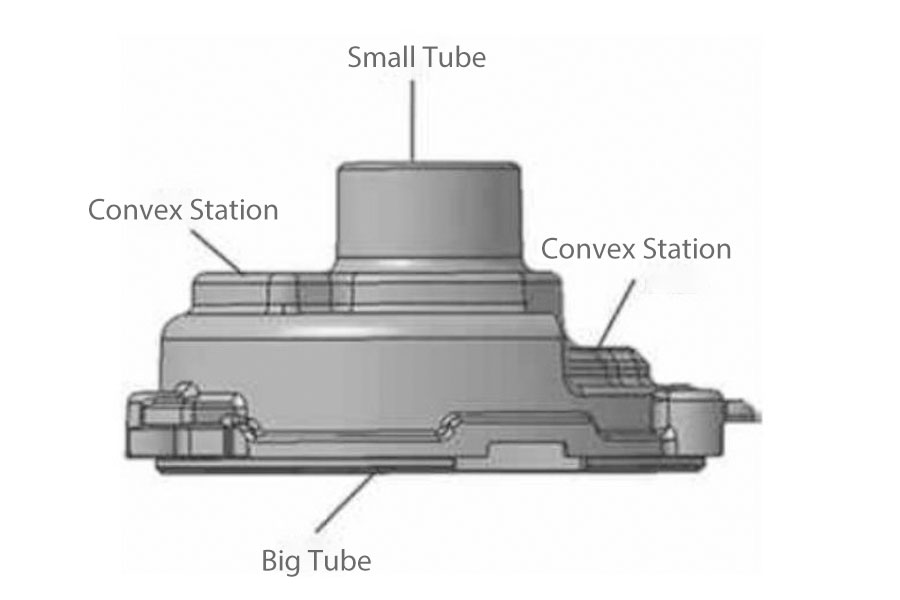

Murfin murfin harsashi na aluminium da aka gabatar a cikin wannan labarin yana da tsari mai sauƙi kuma ɓangarori biyu kawai ake buƙatar sarrafa su. Koyaya, saboda sifar da ba ta dace ba ta harsashi, tsayin shugabannin biyu ya bambanta. Daga cikinsu, matsakaicin matsakaicin waje, tsayi, Babban sassan kaurin bango shine 105mm, 40mm da 3.5mm bi da bi. Sassan da ake buƙatar kera su ne saman saman diamita na manyan da ƙananan harsashi. Dole ne a sarrafa juriya na injin cikin +/- 0.1mm. Tunda wannan ɓangaren baya buƙatar sarrafa ramin ciki, wahalar simintin mutuƙar yana da ƙanƙanta.

Don tabbatar da cewa aikin simintin gyare-gyare na iya cika buƙatun tsayayya da matsin lamba mai ƙarfi sama da 20kN, ana buƙatar sarrafa tsarin samarwa daidai da GB6414-86 CT6 don tabbatar da cewa simintin ba shi da ƙazanta da fasa a lokacin mutu-simintin tsari, da waldi ba a yarda. Gyara samfurin ta hanyar gyara ko tsomawa.

Nazarin Tsarin samfur

2.1 Tsarin samarwa

Tsarin samar da sassan shine: abu mai shigowa → narkewa/mutu simintin → yankan/tsaftacewa → mashin → tsaftace → taro.

2.2 Binciken lahani

Kodayake simintin gyare -gyaren harsashi na aluminium da aka gabatar a cikin wannan labarin yana da tsari mai sauƙi, waɗannan lahani na samarwa sau da yawa suna faruwa yayin aikin samarwa:

- (1) Bambance -bambancen: Bambancin zafin jiki tsakanin ƙarfe da ƙirar, saurin cikawa yayin narkewa, da girman adadin fesawa yayin aiwatar da ƙyallen harbi ba a sarrafa su sosai, wanda cikin sauƙi yana sa launin simintin ya zama duhu da baki.

- (2) Lahani na Porosity: Da kyar za a iya gujewa irin wannan matsalar a cikin tsarin samar da siminti na aluminium. Buƙatar sarrafawa don matsalar porosity na simintin gyare -gyare shine tabbatar da ƙarfin ƙarfin harsashi, kuma ya zama dole don tabbatar da cewa yanki mai mahimmanci baya haifar da porosity wanda ya wuce matsayin ASTME505 matakin 2. The m diamita kewayon pores a cikin simintin gyare -gyare ne ≤∉1.6mm, da rami rami ya kamata a sarrafa a cikin 6.2%, da diamita na pores a kan machined surface kada ta kasance mafi girma fiye da 2.0mm.

Dangane da sarrafa ingancin sarrafawa, dubawa na gani yana da alhakin dubawa na lalatattun bayyanar simintin, kuma binciken X-ray shine ke da alhakin sarrafa ingancin simintin ciki. Koyaya, a cikin samar da taro, daga hangen hanzarta saurin samarwa da sarrafa farashin samarwa, waɗannan hanyoyin guda biyu suna da wasu lahani. Sabili da haka, ana yin nazarin tsarin aikin mutuƙar siminti na aluminium tare da yin magana tare da CAE da sauran fasahohin taimako don haɓaka ingancin asali na simintin gyare-gyare. Ana sarrafa matsalar matsala a cikin mawuyacin hali.

2.3 Sigogi na tsari da zaɓin kayan aiki

Dangane da sifofin tsarin da buƙatun samarwa na simintin gyaran kafa, an saita matsin lamba a 350T. Dangane da ƙwarewar samarwa na irin waɗannan samfuran a baya, kamar haɗaɗɗen ƙirar da ba ta dace ba da zaɓin da bai dace ba na sigogin aiwatarwa, matsalar yawan saurin cika ƙarfe na ƙarfe zai faru yayin aiwatar da simintin mutuwa. , Sakamakon a cikin toshewar iskar gas a cikin rami, kuma a ƙarshe yana haifar da lahani mai inganci kamar ramuka ko ƙazantar oxide a cikin samfurin da aka gama, wanda ke shafar ƙimar wucewa na simintin.

Dangane da buƙatun ƙira na simintin gyare-gyaren, kaurin murfin murfin murfin harsashi mai kauri mai kauri mai kauri kawai 0.8mm ne kawai. Idan an sarrafa shi yadda yakamata, tsarin cibiyar zai zama sako -sako, wanda zai haifar da raguwar aikin harsashi da juriya. Sabili da haka, lokacin ƙera ƙirar, ana amfani da fil ɗin sakawa don daidaita matsayin, kuma ana sarrafa ƙimar sarrafawa tsakanin 0.5mm. Wannan yana adana lokacin sarrafa injin kuma ya fi dacewa don haɓaka ingancin asali na simintin gyare -gyare.

2.3.1 Zaɓin shirin mold

Dangane da buƙatun ƙira na simintin ƙarfe na ƙarfe na aluminium, an aiwatar da ƙirar ƙirar ta amfani da software na AnyCast, kuma an sami tsare-tsaren ƙirar shiga uku daban-daban. Ta hanyar kwatantawa, an ƙaddara tashar kwarara tare da cikewar ruwa mai santsi. Tsarin ƙira na C shine samar da kyawon tsayuwa, kuma ana samun sa a cikin ainihin samarwa cewa wannan shirin yana da tasiri mafi kyau akan inganta lahani na ciki na simintin harsashi da haɓaka yawan amfanin harsashin.

2.3.2 Saitin narkewar zafin jiki

Haɗe tare da nauyin tsarin harsashi na simintin gyare-gyare, ana amfani da injin mutuƙar siminti na 350T don mutuƙar simintin gyare-gyare, kuma an saita zafin jiki a cikin kewayon 640 ℃ +/- 20 ℃. Don tabbatar da matsin lamba na tsarin cika ruwan ƙarfe ya tabbata, yi ƙoƙarin guje wa kwararar Maɗaukaki, fesawa da sauran matsalolin da ke haifar da ɓarna na saƙar oxyidation ko ɓarna na ainihin, an saita ƙimar matsin lamba zuwa 1.3kPa/s.

2.3.3 Tsarkake ruwan gami

Domin haɓaka ingancin simintin gyare -gyaren harsashi na aluminium da rage tasirin ramuka, ramuka, da haɗe -haɗe a kan ƙimar cancantar samfur, ana amfani da matakin tsaftacewa na biyu a cikin aikin simintin gyare -gyaren, wato, an tace murfin sau ɗaya kafin bayan an saki tanderun. A lokaci guda, ana amfani da allon tacewar fiber a bututun ƙarfe, ana amfani da allon tace yumɓu a ƙofar a kwance, kuma ana sanya allon tace fiber-Layer sau biyu a ƙarshen ƙofar a kwance kuma rata ta buɗe don yin tacewa sau uku don sarrafa faruwar lahani samfurin. ƙima.

Yanayin Samar da Haƙiƙa Kuma Tasiri

Dangane da makirci da tsari na sama, an zaɓi samfuran harsashi guda 6 don dubawa a cikin ainihin samarwa, kuma an gano cewa makircin C yana da tasiri mafi kyau akan inganta lahani na ciki na simintin harsashi da haɓaka yawan amfanin harsashin. Ta hanyar binciken X-ray, an gano cewa ƙimar wucewar ikon sarrafawa ya kai 100%; sannan gwajin jujjuyawar daidai ya gano cewa alamar porosity na farfajiyar injin ya kai matakin ASTM E505 matakin 2; ta hanyar gwajin murkushe murkushewa, an gano cewa duk samfuran na iya isa Tsayayya da matsin lamba sama da 25kN. Ana iya ganin cewa ƙirar simintin gyare -gyaren harsashi na aluminium da zaɓin tsari da aka gabatar a cikin wannan labarin suna da ƙima, kuma an sami wasu sakamako wajen sarrafa ingancin samfur.

Kammalawa

Tare da ci gaba da haɓaka kimiyya da fasaha da hanyoyin da ke da alaƙa, an ci gaba da inganta tsarin mutuƙar simintin sassa na aluminium. Gudun aiwatar da alaƙa na gargajiya yana da tsawo, wanda bai dace da sarrafa inganci ba a cikin simintin gyare -gyare. Don tabbatar da haɓaka ingancin samarwa, ya zama dole a fara gudanar da inganci daga matakin kayan. Tsarin samarwa da manyan fasahohin simintin gyare -gyaren harsashi na sama sun kai matsayin da ya dace kuma mai yuwuwa ta hanyar ƙirar kimiyya da zaɓin shirye -shirye, wanda ke tabbatar da cewa fasahohi da hanyoyin da suka dace na iya biyan buƙatun ingancin samar da taro don samfuran simintin da ke da alaƙa, da kuma tabbatarwa. Alloy na aluminum Matsayin mahimman sassan sassan fasahar mutuƙar simintin gyare-gyare a cikin inganta ingancin samfuran da ke da alaƙa.

Da fatan za a adana tushe da adireshin wannan labarin don sake bugawa:Tattaunawar Fasahar Maɓallin Fitar Aluminum Alloy

Minghe Kamfanin 'Yan Wasa Masu Mutu aka sadaukar domin tsirar da samar da inganci da kuma high yi Gyare sassa (karfe mutu simintin sassa Range yafi hada da Thin-Wall Mutu Wasa,Hot Chamber Mutu Wasa,Cold Chamber Mutu Wasa), Zagaye Sabis (Mutuwar 'Yan Wasa,CNC machining,Motsa Motsa, Jiyya na sama) .Adadin al'ada Aluminium ya mutu, magnesium ko Zamak / zinc mutu simintin gyare-gyare da sauran buƙatun simintin maraba don tuntube mu.

Karkashin kulawar ISO9001 da TS 16949, Ana aiwatar da dukkan matakai ta hanyar daruruwan injunan jefa simintin da suka mutu, injunan axis 5, da sauran kayan aiki, tun daga masu fashewa zuwa na’urar Ultra Sonic masu wanki.Minghe ba kawai tana da kayan aiki na zamani ba amma kuma tana da kwararru ƙungiyar ƙwararrun injiniyoyi, masu aiki da sufetoci don tabbatar da ƙirar abokin ciniki ta zama gaskiya.

Manufactureran kwangilar masana'antar mutu. Abubuwan haɓakawa sun haɗa da sassan sanyi na sassan mutuɗar aluminum daga 0.15 lbs. zuwa 6 lbs., saurin canje-canje da aka saita, da aikin inji. Sabis-ƙarin ayyuka sun haɗa da gogewa, faɗakarwa, lalatawa, fashewar harbi, zane, zane, rufi, haɗuwa, da kayan aiki. Abubuwan da aka yi aiki tare sun haɗa da allo irin su 360, 380, 383, da 413.

Zinc ya mutu don jefa ƙirar ƙira / sabis na injiniya tare. Custom manufacturer na daidaici tutiya mutu simintin gyaran kafa. Castananan 'yan simintin gyare-gyare, pressurean ƙwanƙwasa masu juzu'in juzu'in simintin gyare-gyaren juzu'ai, ƙera simintin gyare-gyare na al'ada, ɓangaren mutu da' yan wasa masu mutuwa masu zaman kansu da ƙofar da aka hatimce za a iya ƙera su. Za'a iya kerarrar 'yan simintin a tsayi da faɗi har zuwa 24 a ciki. A cikin +/- 0.0005 a cikin. Haƙuri.

ISO 9001: 2015 bokan masana'anta ta mutu magnesium, Abubuwan haɓaka sun haɗa da matsin lamba na magnesium mai matsi mai yawa har zuwa tan 200 mai ɗumi mai zafi & 3000 ton mai sanyi, ƙirar kayan aiki, gogewa, gyare-gyaren, inji, foda & zanen ruwa, cikakken QA tare da damar CMM , taro, marufi & isarwa.

ITAF16949 bokan. Servicearin Sabis ɗin Gyare Hadawa zuba jari,yashi,Kushin nauyi, Stauren ɓoye ɓoye,Siffar Centrifugal,Cast Vacuum,Dindindin Mould Gyare, .Hanyoyin iyawa sun hada da EDI, taimakon injiniya, ingantaccen samfuri da aiki na sakandare.

Fitar Masana'antu Abubuwan Nazarin sassa don: Motoci, Bikes, Jirgin sama, kayan kiɗa, Jirgin ruwa, Na'urorin hangen nesa, na'urori masu auna sigina, na'urori masu auna sigina, Na'urori, Kayan lantarki, ,unshi, Clocks, Inji, Injiniya, Kayan Kaya, Kayan Jiki, Jigs, Telecom, Haske, Kayan aikin likita, Na'urar daukar hoto, Robobi, Sassaka, kayan sauti, kayan wasanni, Kayan aiki, Kayan wasa da ƙari.

Me Zamu taimake ku yi gaba?

Je zuwa Shafin Farko Don Mutu Wasa China

→Sassan Kasuwanci-Gano abin da muka aikata.

→ Tallan kwankwasiyya Game da Ayyukan Gyare Mutuwa

By Minghe Mutu Wasa Wasa | Categories: Labarai masu Taimakawa |Material Tags: Gyare Aluminum, Zinc Gyare, Fitar Magnesium, Castan Wasanni, Bakin Karfe Cast, Fitar tagulla,Gyare Tagulla,Fitar Bidiyo,Tarihin Kamfanin,Aluminum Mutu Gyare | Comments Off