Maɓallan Maɓallan Sabbin Nau'in Multifunctional Aluminum Alloy Oil Housing Die Casting

Da nufin ci gaban injina na mota zuwa ga nauyi mai sauƙi da haɗin kai, an yi bayani dalla-dalla manyan mahimman abubuwan sabon nau'in kwanon mai na mutuƙar. An raba wuraren fasahar ƙirar ƙirar ƙira zuwa sassa uku, ta amfani da hanyoyi daban-daban na zubar da sabbin fasahohi don ƙera samfura; daga wuraren sarrafa tsarin sarrafa mutuƙar, kowane abin da ke shafar ingancin samfur a cikin tsarin samarwa ana sanya ido don rage ƙimar lalacewar samfur. Ta hanyar waɗannan bangarorin biyu na sarrafawa, ƙimar cancantar samfurin ya wuce 97%, kuma samar da taro ya tabbata.

Tare da saurin haɓaka masana'antar kera motoci, ana gabatar da buƙatu mafi girma akan kayan, ƙira da ƙera sassa, da babban haɗin kai, babban aiki, da ƙarancin farashi sun zama yanayin haɓaka. Duka kwanon mai da ƙananan silinda sune mahimman sassan injin motar. Ta hanyar haɗa madaidaicin ma'aunin ma'aunin silinda da tarin kwanon rufi na mai da aikin tacewa a ɓangaren guda, ana rage nauyi da ƙimar injin sosai. Koyaya, saboda hadaddun tsari da manyan katanga canje -canje, yana buƙatar a raba shi zuwa samfura daban -daban kuma a sarrafa shi daban sannan a haɗa shi da sarrafa shi, wanda ke haifar da matsaloli a masana'antar samfur.

Haɗaɗɗen kwanon mai na injin da aka yi nazari a cikin wannan batun ya ƙunshi simintin gyare -gyare guda uku: jikin kwanon mai, murfin ɗaukar ma'auni da murfin ɗaukar nauyi ɗaya. Yin amfani da kayan A380 da aka gyara, matsakaicin kaurin bango na simintin shine 3 mm, ƙaramin kaurin bango shine 2.5 mm, kuma nauyin fanko shine 10.74 kg. Ana buƙatar rami na ciki ya zama mara-ruwa a ƙarƙashin 300 kPa, kuma ba a fitar da sashin mai a 600 kPa kuma zazzabi ya wuce 60 ℃. Ruwa, wanda aka yi amfani da shi a cikin injinan 1.5T, tare da fitarwa na shekara -shekara na guda 400,000, wanda shine simintin gyare -gyaren bututun mai.

Fasaha fasaha na mutu simintin zane

1.1 Tsarin zane

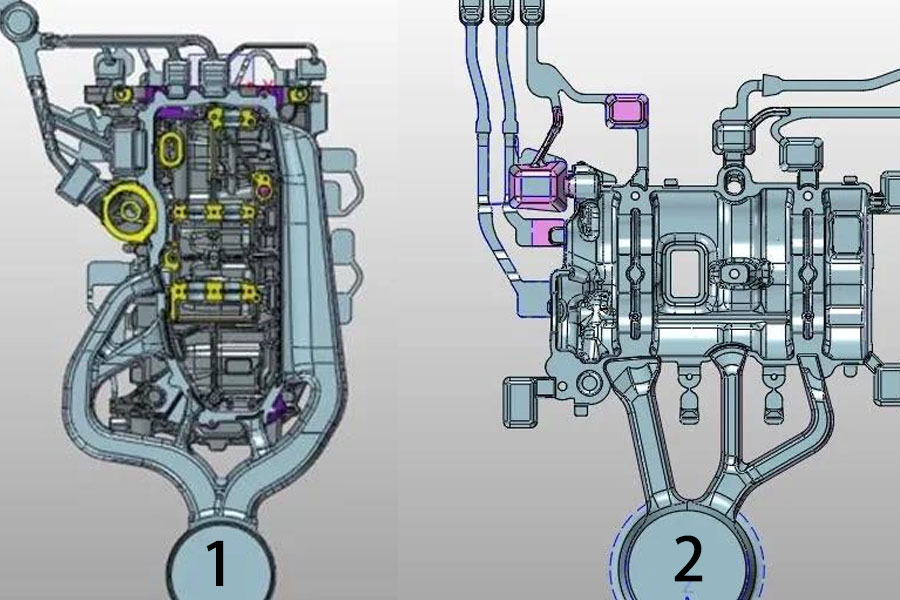

Casting 1 yana ɗaukar ƙirar zubin gefe uku, amma yana mai da hankali kan zubin gaba ɗaya a gefe ɗaya, kamar yadda aka nuna a hoto 1. Kamar yadda samfurin ya yi tsawo (sama da ƙasa ya kai 437.2 mm), ƙirar zubin mai gefe uku na iya sauƙaƙe sauƙaƙe. matsalar dogon aiki, don cika samfurin a fannoni daban -daban. Koyaya, la'akari da cewa kaurin bangon samfurin gaba ɗaya yayi kauri kuma akwai abubuwa da yawa da aka ɗora a wurin zubarwa, don gujewa ruɓewar ƙaƙƙarfan aluminium da aka ƙera, cikawa a gefe ɗaya yana ƙarfafawa, kuma sashin giciye. a hankali an taƙaita yankin gaba ɗaya don hanzarta kwararar ƙirar aluminium. Tsarin zane.

Casting 2 shine murfin ɗaukar ma'auni, tare da siffa mai sauƙi, kawai tsintsin madaidaicin ma'aunin ma'aunin ma'aunin biyu yana da kauri. Dangane da tsarin kwarara mai sauƙi na narkakken aluminium, don adana farashi da haɓaka ƙimar fitarwa mai narkewa na aluminium, an karɓi tsarin zubin gefe ɗaya, kuma an sanya ƙofar a cikin kaurin bangon don ciyarwa, kamar aka nuna a Hoto 2.

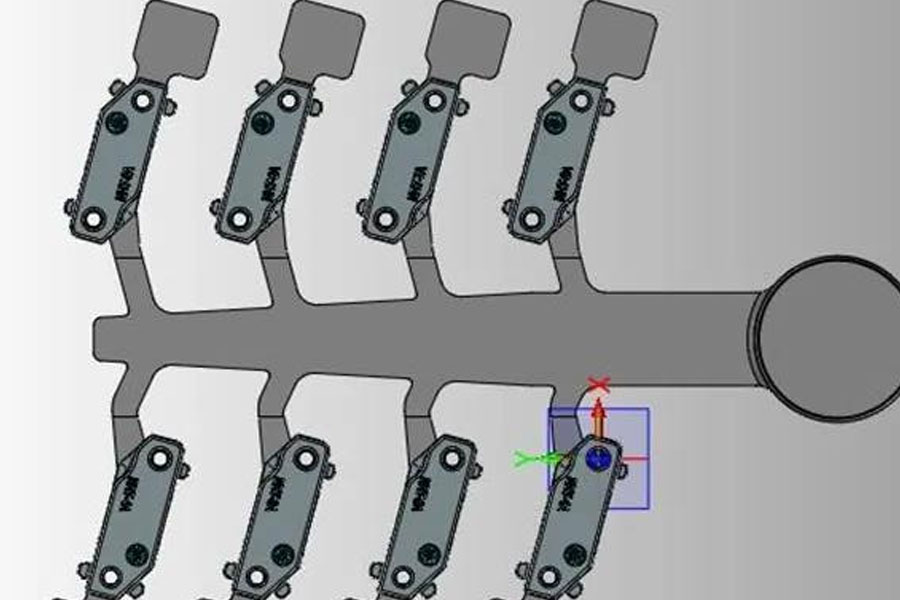

Fitar da 3 shine murfin tayal madaidaiciya madaidaiciya tare da ƙaramin sashi (girman 63 mm) × 15 mm × An karɓi ƙirar rami ɗaya da sifofi takwas don cikawa da zubarwa, kamar yadda aka nuna a cikin hoto 3.

1.2 Hanyar shaƙewa

Don simintin simintin gyare -gyare 1, ana amfani da babban injin don shaye -shaye. Fitowa ta 2, ta amfani da katanga mai banƙyama ta “washboard”. Casting 3 kai tsaye yana ɗaukar jakar slag da tashar murfin murfin murfin a wutsiyar jakar slag. An nanata mahimman mahimman fasahar shaye -shaye na simintin 1.

Tun da manyan hanyoyin matse mai da matatun mai na simintin gyare-gyare suna mai da hankali a cikin wutsiyar ruwa, tasirin wutsiyar wutsiyar ruwa shine babban abin da ke ƙayyade ingancin ciki na waɗannan wuraren. Simintin 1 yana amfani da babban ɓoyayyen injin don rage matsin lamba a cikin mummunan matsin lamba na wutsiyar ruwa na simintin. Da farko, ƙimar tankin injin ɗin dole ne a zaɓi L 800 L (800 L a nan ya ninka sau 10 na ƙarar ƙirar da ke ɗauke da rami da tulu) don hanzarta samar da tashar matsin lamba. Abu na biyu, bututun da ke haɗe da injin da injin injin dole ne a rufe shi da iska, kuma yakamata a kiyaye digirin injin bututun a cikin 2 000 Pa. Na uku, an rufe murfin tare da tef ɗin rufewa, da duk babban jigon da babban fil. an rufe su da sealant. Bayan an rufe murfin, dole ne a kiyaye ramin rami tsakanin 4 000 Pa. A ƙarshe, zaɓi mafi kyawun samarwa na bugun da aka hatimce, ko amfani da ƙaramin sigar bugun don ƙara yankin hatimin bugun, kuma a sauƙaƙe sauƙaƙe zubar iska a cikin rami.

1.3 Mould zazzabi

Dangane da halayen babban injin, narkakken aluminium ba a cika cika shi daidai da yanayin ruwa ba (duba Figure 4), kuma narkakken aluminium yana da sauƙin saurin ƙarfafawa a wasu wurare lokacin da aka tsotse cikinsa, yana haifar da lahani na mutuwa. kamar yadda ake zubar da pores, ramukan ramuka, da fasa. Samfurin wannan simintin gyare -gyare 1 yana farawa da ɓarna lokacin da naushi ya motsa zuwa matsayi na 410 mm (cikakken ruwan aluminium ya kai abin da ake buƙata na 70%), kuma yana rufe injin a matsayin 540 mm. Lokaci), bugun injin shine 130 mm, kuma lokacin shine 0.874 s. A cikin irin wannan ɗan gajeren lokacin, dole ne a tabbatar cewa ruwan da aka zana na aluminium ba zai ƙarfafa a cikin wani muhimmin matsayi a cikin wutsiyar ruwa a gaba ba. Sabili da haka, ana sarrafa zafin jiki a waɗannan wurare a 220 ℃ da 180 ℃ bi da bi ta amfani da injin zafin mai. Ƙara yawan zafin jiki na mold da haɓaka haɓakar ƙarfe na aluminium shine mabuɗin don tabbatar da ingancin cikin waɗannan muhimman wurare guda biyu.

Casting 2 da 3 suna da sauƙi a cikin tsari, gajarta a cikin cika cika, kuma mai sauƙin tsari. Ba sa buƙatar zazzabi mai ƙyalli mai ƙarfi, muddin ƙirar ƙirar tana da girma kuma samfur ɗin ba ya zama baƙi.

1.4 Zaɓuɓɓukan sanyaya Mould

Wannan simintin gyare-gyare na 1 yana amfani da fasahar sanyaya manyan maki da fasahar samar da ruwa na lokaci-lokaci. Tun da samar da simintin gyare -gyare yana buƙatar kula da zafin jiki mafi girma, kuma akwai ƙarin shugabani a gefen ƙirar motsi, ya zama dole don tabbatar da cewa ba a tabbatar da babban zafin ba kawai, amma kuma abubuwan da aka ɗaga ba za su samar da haɗin gwiwa mai zafi ba raguwa da raguwa da sauran lahani. Ana yin aikin yanke don kowane sakawa, kuma ana sanya sanyaya tabo cikin cikin abin da aka saka. Daidaitaccen kayan aiki na gefe yana amfani da hanyar samar da ruwa na lokaci -lokaci. A lokacin matakin ƙarfafawa na samfur, ana buɗe bawul ɗin solon don sanyaya samfurin a gida. Wannan ba kawai yana samun zazzabi mafi girma ba, har ma yana samun sakamako mai sanyaya mai kyau. An tsara babban tsarin sanyaya wuri don allurar gindin mutuƙar, kamar yadda kibiya ta nuna a cikin Hoto na 1. Allura 4 mm a tsakiyar yankin kaurin bangon zai haifar da raguwa kai tsaye. Ana amfani da ƙirar sanyaya-madaidaiciya don allurar 4 mm, wanda zai iya magance matsalar ramin ramin da aka ɗaure. Hakazalika, a wasu wurare masu zafi, ana amfani da ƙirar allurar sanyi mai tsananin zafi inda za a iya fitar da allurar, wanda ke sauƙaƙa matsalolin ƙonewa, stomata, da allurar da ta karye. Saitin lokacin sanyaya madaidaici da isasshen ruwa yana buƙatar yin la’akari da kaurin bango na ramin kayan da wurin da yake. Don haka, allurar sanyi a waɗannan fannoni daban -daban na buƙatar sarrafa yankin.

Casting 2 kawai yana da ramin rami na 4 mm a tsakiyar ma'aunin ma'auni da ramin ƙulle Φ8 mm a mashigar abinci, wanda ke amfani da madaidaicin madaidaicin sanyi. Saboda bayan an murƙushe ruwan aluminium, za a samar da tashar sako-sako tsakanin wuraren kaurin bango na tsakiya, dole ne a yi amfani da allurar sanyi mai wuce-wuri don tilasta ƙara ƙarfi a kusa da ramin rami, tare da jinkirta 1 s da sanyaya don 10 s. Ƙananan allurai 16 na Φ8 mm a cikin simintin 3 duk suna amfani da kulawar sanyi mai ƙarfi don kula da kaurin babban lebur kusa da ramin rami.

1.5 Zaɓin fasahar extrusion na gida

Filin extrusion na cikin gida zai iya magance ƙuntatawa a cikin yanki mai kauri kuma ana amfani dashi sosai a fagen mutuƙar simintin. Ana nuna yadda ake sarrafa gabobin da ke haɗe da gidajen abinci masu zafi a cikin Hoto na 5. Akwai haɗe -haɗe masu zafi da yawa a cikin simintin gyare -gyare 1, kuma dole ne a shirya matsayin firam ɗin extrusion. Na farko, kawar da nodes masu zafi waɗanda za a iya kawar da su ta amfani da allurar sanyi, na biyu kuma kawar da nodes masu zafi waɗanda ba sa cikin mahimman matsayi. A ƙarshe, kuna buƙatar yin la’akari da tsari na matattarar pin silinda a cikin sarari na ciki. Gabaɗaya an shirya shi a wani wuri inda tsarin yake da rikitarwa kuma ana hana fitar da iska ..

Key maki na mutu simintin aiwatar da iko

2.1 Gudanar da kwararar feshin yayin simintin mutuwa

Yayin aiwatar da aikin mutuƙar, ana auna ƙimar kwararar ruwa daban-daban ta hanyar motsi da tsayayyen kyawon tsayuwa, ana sarrafa ƙirar motsi a 3 200 ml, kuma ana sarrafa madaidaicin ƙirar a 2 200 ml. Bugu da ƙari, an saita ƙimar karkace babba da ƙarama daban don ƙima mai ɗimbin juzu'i. Tun lokacin da aka zaɓi kwararar wutar lantarki yana da madaidaicin 50 mL, karkacewar saitin shine m 200 mL, kuma 200 mL shine ainihin ƙimar da aka auna bayan an rage bindiga ɗaya. A yayin aikin samarwa, idan ƙimar karkacewa ta wuce, za a fitar da siginar ƙararrawa kai tsaye don dakatar da sake zagayowar aikin mutuƙar simintin. Sabili da haka, yana iya hana hana katange fesawa saboda bindiga mai fesawa, wanda na iya haifar da kumburi da ƙonewa.

2.2 Gudanar da sarrafa zafin zafin aluminium

Tun da tasirin adana zafi na tanderun riƙe yana da kyau, amma ƙimar dumama yana da hankali fiye da na wutar makera mai yawa, dole ne a sarrafa sarrafa zafin da ke narkar da aluminium. Zaɓin zafin da aka narkar da aluminium shine 675 ± 10 ° C, don haka dole ne a kiyaye zafin zazzabin aluminium a cikin ladle na sufuri sama da 700 ° C. Ciyar da ke ƙasa da wannan zafin jiki zai shafi yanayin kwararar aluminium mai narkewa yayin aikin cikawa, wanda ke haifar da ƙaruwa a cikin adadin ramuka a wuraren gida. Ƙara kayan sama da 730 ℃ zai haifar da ƙonewa da ƙyalli na aluminium a saman ƙirar, wanda zai shafi ingancin bayyanar simintin. Saita ƙararrawa na zafin jiki na narkakken aluminium don tanderun riƙewa. Idan zazzabin da ke zubowa baya cikin kewayon, wutar makera za ta firgita kuma ta dakatar da jujjuyar samar da mutuƙar, wanda zai iya hana lahani ta hanyar karkacewar zafin jiki na narkakken aluminium.

2.3 Gudanar da injin

Tun lokacin da aka toshe simintin gyare -gyaren 1 tare da madogarar madaidaiciyar madaidaiciyar madaidaiciyar madaidaiciya, an rufe dukkan babban jigon da babban maƙallan ta hanyar yin amfani da sealant, kuma ƙaƙƙarfan ma mahimmin juzu'i ne, amma naushi baya amfani da naushi na musamman na musamman, amma yana amfani wani farantin farantin fakitin (wanda aka mika shi zuwa 150 mm). A cikin irin wannan yanayin da aka rufe, ƙararrawa za ta haifar lokacin da aka saita matakin injin ɗin ya wuce 4 kPa (4 kPa ƙimar ƙarar ƙararrawa ce da aka saita gwargwadon girman ƙimar wucewa yayin aikin samarwa), kuma digirin injin yana kusan 2.3 k Ba. Tsabtacewa da ƙimar dabi'un suna kusa da 101 kPa, kuma ƙarar ƙarar ƙararrawa ita ce 90 kPa (an saita 90 kPa gwargwadon tsarin tsabtace tankin tace a cikin masana'anta). A ƙarshen sake zagayowar tsabtatawa, yakamata a tsabtace tankin matattarar matattarar matatun mai a cikin lokaci. Rashin tsaftace shi zai shafi tasirin gurɓataccen abu. Ƙimar saitin tankin injin shine 1 kPa, wanda gabaɗaya tsakanin 2.2 zuwa 400 Pa. Muddin ƙimar da ake buƙata ta wuce, za a ba da ƙararrawa kuma za a rufe injin simintin mutuwa.

2.4 Kula da ainihin sigogi na allura

Na'urar mutu-simintin tana ɗaukar samfurin Ube 1650T na cikin gida. Baya ga tsarin sarrafa siginar injin kansa, yana kuma amfani da tsarin bin diddigin lambar lamba biyu (wanda ake kira tsarin MES a cikin masana'anta) don haɗa injin mutu-simintin da kayan aikin na gefe don tsarin MES ya iya Karanta sigogin samarwa na kowane ƙirar a cikin ainihin lokaci kuma ciyar da su zuwa ga girgije don kwatantawa a cikin gajimare (ƙimar kwatancen girgije an shiga cikin girgije a gaba kamar yadda ake buƙata, kuma ana fitar da ƙimomi daban -daban gwargwadon ainihin nasarar daban -daban Misali. . Cloud Big Data kuma a kai a kai yana lissafin alakar-lokaci tsakanin tsufan samfur da canje-canjen saiti dangane da ƙarar bayanan da aka sabunta. Nemo dalilan sauye -sauye a cikin ragin ragi a cikin lokaci, da haɓaka ƙimar ƙimar samfuran. Akwai canje-canje a cikin tsarin samar da mutuƙar simintin, wanda zai iya gano wuraren matsalar cikin sauri kuma ya inganta ingantaccen zagayowar daidai a wurin.

2.5 Sarrafa sufurin ruwa mai mutuwa

A farkon safarar ruwa, kowane layi yana amfani da bawul ɗin solenoid don sarrafa lokacin sanyaya kai tsaye ko ma'anar ruwan sanyi mai sanyi. Matsawar ruwa shine 0.4 MPa kuma zafin ruwan shine 30 ℃ ruwa mai tsabta. Ban da tulu, hannun riga, kayan aiki, naushi, tsagewar mazubi da hannun riga da kayan da aka tilasta farantin sanyi wanda yawanci ana buɗewa da sanyaya kai tsaye, duk sauran sanyaya kai tsaye (shingayen ruwa) da sanyaya babban wuri ana sarrafa su ta hanyar bawul ɗin solenoid, jinkiri 3 s, sanyaya 15 s don tabbatar da yawan zafin jiki. Duk allurai, daga Φ4 mm zuwa Φ14 mm (tsakiyar bututu daga Φ1.5 mm zuwa Φ5.5 mm) ana sarrafa su ta hanyar babban mahimmin sanyi, babban matsin jigilar ruwan sanyi shine 10 MPa, da zazzabin jigilar ruwa shine 10 ℃ (a nan Ba za a iya saita zafin jiki da ƙasa ba, ƙanƙantar da kai zai ɗauki ƙarin zafi, amma zai iya haifar da allurar da ta karye), kowane rukuni na allurar sanyi mai girman gaske bai wuce 8 ba (fiye da allura 8 sun wuce diamita na diamita G1/2 mai haɗa bututun bututu), duk allurar an haɗa su cikin jimlar ƙungiyoyi 6, ban da allurar sanyi ta mm4 mm, lokacin jinkiri shine 5 s kuma sanyaya shine 13 s, kuma Φ4 an saita allurar sanyi mai sanyi don jinkirta 4 s kuma lokacin sanyaya shine 13 s don yin niyya ga filin zafin jiki. A cikin yankin da ke buƙatar sanyaya da sauri, rage faruwar wuraren zafi. Ba wai kawai yana ba da tabbacin daidaituwa da adana zafi na zazzabi mai zafi ba, har ma yana kawar da wuraren zafi na gida kuma yana ba da tabbacin ingancin samfur.

3. Ingancin sabon kwanon mai mai yawan aiki. Ana samar da samfuran guda uku a kan injinan daban -daban guda biyu, kuma yawan fitowar yau da kullun ya kai guda 980/rana, guda 1,500/rana, da guda 12,000/rana daga jifa 1 zuwa jefawa 3. Gabaɗaya adadin wucewar samfuran uku har zuwa Babban taro ya kai kashi 97%. Hoto na 8 hoto ne na bayyanar simintin gyare -gyare na 1, 2 da ingancin ciki na simintin 1, 2, da 3.

Kammalallen 4

- Abubuwan ƙira da fasaha na wannan sabon nau'in kwanon mai shine sassauƙar amfani da injin, sanyaya tabo, extrusion, ma'aunin zafin jiki da sauran matakai a ƙarƙashin nau'ikan juzu'i 3 da hanyoyin shaye -shaye daban -daban, kuma ana haɗa aikin ƙarshe a cikin Abubuwan guda ɗaya.

- Babban mahimmancin sarrafa mutuƙar simintin shine ci gaba da zurfafa bincike da sanya ido kan abubuwan da ke shafar rashin ingancin samfur, don cimma ingantaccen tsarin samarwa.

- Bayan wucewa ƙirar shirin farko da ganowa da nazarin wuraren fasaha, an karɓi sarrafa tsarin da ke sa ido akan sa ta atomatik, don haka qu

Da fatan za a adana tushe da adireshin wannan labarin don sake bugawa: Maɓallan Maɓallan Sabbin Nau'in Multifunctional Aluminum Alloy Oil Housing Die Casting

Minghe Kamfanin 'Yan Wasa Masu Mutu aka sadaukar domin tsirar da samar da inganci da kuma high yi Gyare sassa (karfe mutu simintin sassa Range yafi hada da Thin-Wall Mutu Wasa,Hot Chamber Mutu Wasa,Cold Chamber Mutu Wasa), Zagaye Sabis (Mutuwar 'Yan Wasa,CNC machining,Motsa Motsa, Jiyya na sama) .Adadin al'ada Aluminium ya mutu, magnesium ko Zamak / zinc mutu simintin gyare-gyare da sauran buƙatun simintin maraba don tuntube mu.

Karkashin kulawar ISO9001 da TS 16949, Ana aiwatar da dukkan matakai ta hanyar daruruwan injunan jefa simintin da suka mutu, injunan axis 5, da sauran kayan aiki, tun daga masu fashewa zuwa na’urar Ultra Sonic masu wanki.Minghe ba kawai tana da kayan aiki na zamani ba amma kuma tana da kwararru ƙungiyar ƙwararrun injiniyoyi, masu aiki da sufetoci don tabbatar da ƙirar abokin ciniki ta zama gaskiya.

Manufactureran kwangilar masana'antar mutu. Abubuwan haɓakawa sun haɗa da sassan sanyi na sassan mutuɗar aluminum daga 0.15 lbs. zuwa 6 lbs., saurin canje-canje da aka saita, da aikin inji. Sabis-ƙarin ayyuka sun haɗa da gogewa, faɗakarwa, lalatawa, fashewar harbi, zane, zane, rufi, haɗuwa, da kayan aiki. Abubuwan da aka yi aiki tare sun haɗa da allo irin su 360, 380, 383, da 413.

Zinc ya mutu don jefa ƙirar ƙira / sabis na injiniya tare. Custom manufacturer na daidaici tutiya mutu simintin gyaran kafa. Castananan 'yan simintin gyare-gyare, pressurean ƙwanƙwasa masu juzu'in juzu'in simintin gyare-gyaren juzu'ai, ƙera simintin gyare-gyare na al'ada, ɓangaren mutu da' yan wasa masu mutuwa masu zaman kansu da ƙofar da aka hatimce za a iya ƙera su. Za'a iya kerarrar 'yan simintin a tsayi da faɗi har zuwa 24 a ciki. A cikin +/- 0.0005 a cikin. Haƙuri.

ISO 9001: 2015 bokan masana'anta ta mutu magnesium, Abubuwan haɓaka sun haɗa da matsin lamba na magnesium mai matsi mai yawa har zuwa tan 200 mai ɗumi mai zafi & 3000 ton mai sanyi, ƙirar kayan aiki, gogewa, gyare-gyaren, inji, foda & zanen ruwa, cikakken QA tare da damar CMM , taro, marufi & isarwa.

ITAF16949 bokan. Servicearin Sabis ɗin Gyare Hadawa zuba jari,yashi,Kushin nauyi, Stauren ɓoye ɓoye,Siffar Centrifugal,Cast Vacuum,Dindindin Mould Gyare, .Hanyoyin iyawa sun hada da EDI, taimakon injiniya, ingantaccen samfuri da aiki na sakandare.

Fitar Masana'antu Abubuwan Nazarin sassa don: Motoci, Bikes, Jirgin sama, kayan kiɗa, Jirgin ruwa, Na'urorin hangen nesa, na'urori masu auna sigina, na'urori masu auna sigina, Na'urori, Kayan lantarki, ,unshi, Clocks, Inji, Injiniya, Kayan Kaya, Kayan Jiki, Jigs, Telecom, Haske, Kayan aikin likita, Na'urar daukar hoto, Robobi, Sassaka, kayan sauti, kayan wasanni, Kayan aiki, Kayan wasa da ƙari.

Me Zamu taimake ku yi gaba?

Je zuwa Shafin Farko Don Mutu Wasa China

→Sassan Kasuwanci-Gano abin da muka aikata.

→ Tallan kwankwasiyya Game da Ayyukan Gyare Mutuwa

By Minghe Mutu Wasa Wasa | Categories: Labarai masu Taimakawa |Material Tags: Gyare Aluminum, Zinc Gyare, Fitar Magnesium, Castan Wasanni, Bakin Karfe Cast, Fitar tagulla,Gyare Tagulla,Fitar Bidiyo,Tarihin Kamfanin,Aluminum Mutu Gyare | Comments Off