Dalilai Uku Don Narkawar Narka yayin Samar da Moda

Idan aka kwatanta da molds masu gudu na yau da kullun, tsarin gating a cikin injin mai zafi mai zafi koyaushe yana cikin babban zafin jiki yayin amfani, kuma narkar da filastik yana da saurin zubewa a gabobin sassan tsarin mai gudu mai zafi a ƙarƙashin aikin babban zafin jiki da ƙima. matsi. Ruwan narkewa ba zai shafi ingancin sassan filastik kawai ba, har ma yana lalata ƙirar sosai, wanda ke haifar da rashin samarwa. Akwai ɓangarori biyu masu ɓarna na ƙirar mai gudu mai zafi, ɗayan shine ƙarshen fuskar mai gudu akan farantin mai gudu, ɗayan kuma shine saman mahaɗin farantin mai gudu da bututun ƙarfe (gami da bututun ƙofa da babban bututun mai gudu) . Akwai dalilai da yawa na narkar da zubewar ruwa, waɗanda za a iya taƙaita su zuwa fannoni uku: aiki mara kyau, tsarin taro, da ƙirar sealing mara ma'ana. Wannan labarin ya gabatar da abubuwan da ke haifar da narkewar yoyo da matakan kariya.

Narkewa yayyo sanadiyyar abubuwan aiwatarwa

Fasahar aiki mara inganci tana ɗaya daga cikin manyan dalilan narkar da zubar ruwa yayin samarwa. Domin ramawa don fadada dumamar sassan sassan mai gudu mai zafi, sau da yawa akwai wani ɗan tazara mai sanyi tsakanin sassan lokacin zayyanawa da haɗa ƙirar. Kawai a ƙarƙashin ƙayyadaddun zafin aiki, haɓakawar zafin jiki na sassan na iya kawar da gibin sanyi gaba ɗaya da cimma rigakafin sealing da yoyo. Ruwan narkewa wanda ke haifar da aiki mara kyau galibi yana faruwa a cikin waɗannan yanayi:

- Ruwan narkewa wanda ke haifar da tsarin dumama mara kyau ko sarrafa zazzabi mara daidaituwa. A lokacin aikin dumama, idan ƙarar bututun bututun ƙarfe ya fi ƙimar dumama farantin mai zafi mai zafi, faɗaɗa axial thermal na sassan tsarin zai iyakance haɓakar zafi mai zafi na farantin mai zafi, yana haifar da farantin mai zafi mai zafi ya lalace. haifar da narkewa. Yanayin rashin daidaituwa na sassan tsarin ƙofar zai haifar da faɗaɗa ɓangarorin ba daidai ba, kuma zai sa sassan su lalace kuma su haifar da narkewar ruwa.

- Yi allura a gaba lokacin da tsarin bai kai takamaiman zafin aiki ba. Kamar yadda aka nuna, bayan tsarin ya yi zafi, zoben goyan baya 6, farantin mai gudu 5 mai zafi, kuma ƙofar bututun ƙarfe 4 yana fuskantar faɗaɗawar zafi a cikin madaidaicin axial, kuma an matsa zoben goyan baya akan madaidaicin farantin farantin 3, da wani ana samun adadin zafi tsakanin farantin mai gudu mai zafi da bututun ƙarfe. matsi. Idan an yi allurar lokacin da ba a kai takamaiman zazzabi ba, matsin lambar da ke haifar da haɓaka zafi bai isa ya daidaita matsatsin narkewa ba, wanda zai haifar da bututun ƙarfe 4 da farantin mai gudu 5 don rarrabewa da haifar da zubewar narkewa.

- Ruwan narkewa ya haifar da zafin dumama tsarin sama da zafin aiki. A wannan yanayin, saboda haɓaka zafi mai yawa, za a samar da babban matsin lamba, wanda zai sa sassan tsarin su lalace da narkewa.

A gefe guda, lokacin da aka rage zafin zafin tsarin gating zuwa zafin zafin aiki, narkewar narkewa kuma zai faru saboda rashin daidaituwa na bututun zafi tare da tsauraran gefuna zuwa faɗaɗa zafi.

A taƙaice, yin aiki gwargwadon madaidaitan matakai da yanayin aiwatarwa shine abin da ake buƙata don guje wa narkewar ruwan. Za'a iya sarrafa madaidaicin mai gudu mai zafi gwargwadon matakai masu zuwa:

- Zafi tsarin mai gudu mai zafi zuwa zafin da aka saita. Gabaɗaya an kasu kashi biyu: Na farko shine farawa mai laushi don kawar da danshi a cikin hita.

- Zafi da mold zuwa saita zafin jiki. Musamman ga manyan kyawon tsayuwa, ana zafi kafin allura sannan a sanyaya yayin allura.

- Zafi ganga na injin allura zuwa zafin da aka saita Mataki na biyu shine don dumama tsarin zuwa yanayin zafin da aka saita da cikakken nauyi. Za'a iya yin zafi da bututun ƙarfe zuwa 2/3 na zafin farantin mai gudu. Bayan zafin zafin farantin mai zafi ya kai ƙirar ƙirar, ƙwanƙirin bututun yana zafi zuwa zafin da aka saita.

- Don sabon ko tsabtace tsarin mai gudu mai zafi, yakamata a fara amfani da allurar sannu a hankali.

- Idan babu raguwar narkewa bayan da yawa allurar allura, ana amfani da sigogin tsarin allurar don samarwa.

Tsarin sealing na tsarin mai gudu mai zafi

Biyan fadada zafi na tsarin mai gudu mai zafi

Kullin da aka taru a zafin jiki na ɗaki zai sa matsayin dangi na sassan ya canza yayin haɓaka zafi na sassan tsarin mai gudu mai zafi. Domin ramawa don haɓaka ɗimbin sassan, ya zama dole a bar rata mai dacewa, kamar ramin sanyi A da C da aka nuna. An gyara shi akan madaidaicin samfuri 1 ta wurin saka matsayi na tsakiya 7 kuma yana shimfidawa bayan an yi zafi. Fadadawar zafi na farantin farantin mai zafi zai rage rata A tsakanin farantin mai zafi mai zafi da fil ɗin anti-rotation 2. Idan ƙimar A ta yi ƙanƙanta fiye da haɓakar zafi mai zafi na faranti mai zafi a cikin ƙira, anti- juyawa juyawa zai hana tsawaitawar farantin mai gudu mai zafi bayan dumama.

Yana haifar da ɓarna da ɓarna na farantin mai gudu mai zafi, wanda ke sa hatimin tsakanin farantin mai gudu mai zafi da bututun ƙarfe ba shi da tasiri kuma yana haifar da narkewa. Ƙarfafa yanayin zafi na zoben goyan baya 6, farantin mai gudu mai zafi 5, da ƙofar ƙofar 4 za ta kawar da rata mai sanyi C. Idan raunin sanyi ya yi yawa kuma faɗaɗawar yanayin zafi bai isa ba, matsin narkewa yayin allura zai haifar ƙofar bututun ƙarfe 4 da mai gudu mai zafi An raba farantin 5 kuma narkewar ta zube. Idan rata mai sanyi ya yi ƙanƙanta kuma matsin faɗaɗa na tsarin yana da girma sosai, sassan tsarin za su lanƙwasa, ko matsin lamba zai wuce ƙarfin samar da samfur ɗin da aka gyara, wanda zai sa zobe na goyan baya ya murkushe samfuri, ta hakan yana iyakance faɗaɗawar gefe na gefe na farantin mai zafi mai zafi kuma yana haifar da ƙofar narkar da ruwan ya faru tsakanin bututun ƙarfe da farantin mai zafi.

Sabili da haka, lokacin ƙera ƙirar, daidai ƙididdige ɗimbin ɗimbin tsarin da barin rata mai faɗaɗawar zafi mai dacewa shine abubuwan da ake buƙata don hana narkewar ɓarna. Za'a iya lissafin faɗaɗawar yanayin zafi na tsarin ta hanyar dabara mai zuwa: L = TL (1) Damuwar zafin da ke haifar da juriya na faɗaɗa yanayin tsarin shine: = EL-CL (2) Matsalar madaidaicin ƙirar ana duba madaidaicin farantin ta hanyar dabarar da ke biye (p) (3) inda: L Shine faɗaɗaɗaɗɗen ɗanyen ɗimbin tsarin mai gudu mai zafi, mm; shine madaidaicin faɗaɗawar ɗigon ɗimbin kayan kayan tsarin; T shine bambancin zafin jiki tsakanin sassan tsarin mai gudu mai zafi da ƙirar; L shine tsawon sassan tsarin mai gudu a cikin hanyar fadadawa a zafin jiki na ɗaki, mm; shine tsarin dumamar yanayi Tsarin damuwar ta haifar da juriya, MPa; C shine adadin rata da aka tanada, mm; E shine ƙirar na roba na sassan tsarin, MPa; p shi ne halatta danniya na matsi na kayan aikin farantin mold.

Tsarin sealing na tsarin mai gudu mai zafi

Hatimin jirgin sama tsakanin farantin mai gudu mai zafi da bututun ƙarfe sigar sifa ce ta gama -gari a cikin tsarin masu gudu mai zafi na ƙasashen waje. Bayan an fadada tsarin da zafi a cikin axial shugabanci, ana danna maɓallin goyan baya akan farantin ƙirar madaidaiciya, kuma ana haifar da wani matsin lamba a cikin jirgin haɗin gwiwa na farantin mai zafi mai zafi da bututun ƙarfe don daidaita matsin lamba don rufewa da hanawa. yayyo. Irin wannan tsarin ba zai iya ba da garantin hatimin sanyi ba, kuma babu ma'aunin kariya mai zafi. Sai kawai a ƙarƙashin yanayin zafin jiki da aka saita za a iya rufe farantin mai gudu mai zafi da bututun ƙarfe. Lokacin ƙira, ya zama dole don ƙididdige ƙimar zafi sosai kuma bar rata mai sanyi mai dacewa C.

b. Ana amfani da zoben sealing na O-dimbin yawa akan jirgin haɗin gwiwa na bututun ƙarfe da farantin mai gudu mai zafi. O-dimbin yawa sealing zobe da aka yi da bakin karfe bututu. Lokacin haɗuwa, akwai preload na 2030 bututu na ƙarfe don hana narkewa. Wannan tsarin ya dace sosai don faranti masu gudu masu zafi da ƙarancin ƙarfi.

An karɓi haɗin na roba, kuma bazara tana ba da tashin hankali kafin a gane hatimin a ƙarƙashin yanayin sanyaya. Lokacin zafi fiye da kima, bazara tana ɗaukar fa'idar zafi don hana lalacewar tsarin da ɓarna. Siffar hatimi ce mai kyau.

An gyara bututun ƙofar a kan farantin mai zafi mai zafi ta zaren, kuma bututun ƙarfe da zoben matsin lamba yana motsawa tare da farantin mai zafi lokacin da tsarin ke ƙaruwa. Tun da motsi na bututun zai haifar da misalign na bututun mai gudu da bututun ƙofar akan madaidaicin samfuri, yakamata a yi la’akari da faɗaɗa yanayin zafi na gefe yayin zayyana matsayin bututun. Irin wannan hatimin ya dace da lokatai da pointsan wuraren allura da ƙananan tazara.

Hot runner farantin taro tsari

Daidaiton taro da jerin shigarwa na tsarin mai gudu mai zafi suna da alaƙa kai tsaye ko narkewar ta narke. Idan tsayin bututun bai dace ba, rata tsakanin gajeriyar bututun ƙarfe da farantin mai zafi mai zafi zai haifar da narkar da ruwa, da ɓarna na farantin mai zafi mai zafi wanda ya haifar da rashin daidaituwa na kushin tallafi da tsayin bututun ma zai haifar da narkewa.

Mai zuwa yana ɗaukar 1-mold 4-cavity filastik akwati mai zafi mai zafi azaman misali don kwatanta tsarin taro na farantin mai zafi mai zafi:

- Da kyau gyara farantin gyaran kwandon shara.

- Danna maɓallin mai gudu 7 a cikin farantin mai gudu 10 mai zafi, shigar da maɓallin juyawa 2 bayan gyara shugabanci, sannan danna maɓallin tare da dunƙule matsawa 3, kuma yi amfani da zobe na ƙarfe na O-dimbin yawa don hana narkewa daga zubewa. .

- Shigar da bututun ƙofar 1 da kushin goyan baya 15 a cikin madaidaicin samfuri 14, kuma bincika ko tsayin duk jiragen taro na bututun ƙarfe iri ɗaya ne bisa madaidaicin jirgin samfuri. Idan ba su dace ba, yi niƙa a mafi ƙarancin ƙima, tare da haƙuri na 0.01mm.

- Yi ƙoƙarin shigar da farantin mai zafi mai zafi kuma duba ko farantin mai gudu mai zafi da maɓallin jujjuyawar juzu'i 2 suna da takaddama masu mahimmanci A da B a cikin radial da axial kwatance.

- Gyara firam ɗin farantin goyan baya 12 akan madaidaicin samfuri 14 tare da kusoshi.

- Dangane da jirgin sama na firam ɗin goyan baya 12, gyara duk zoben matsin lamba 6 don sanya su daidaituwa cikin tsayi kuma su sami rata tare da jirgin sama na firam ɗin goyan baya. C.

- Dunƙule babban bututun ƙarfe 9 a cikin farantin mai gudu 10.

Da fatan za a adana tushe da adireshin wannan labarin don sake bugawa:Dalilai Uku Don Narkawar Narka yayin Samar da Moda

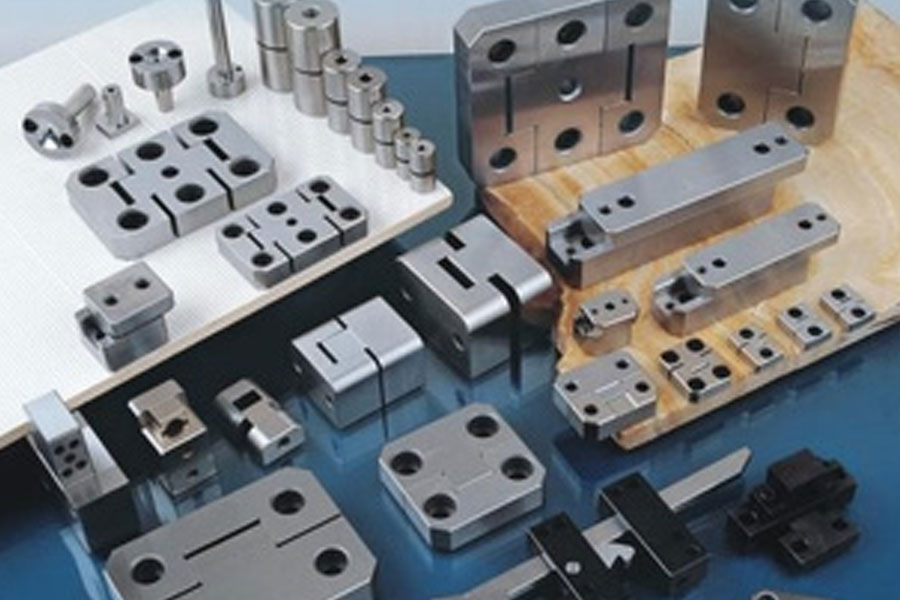

Minghe Kamfanin 'Yan Wasa Masu Mutu aka sadaukar domin tsirar da samar da inganci da kuma high yi Gyare sassa (karfe mutu simintin sassa Range yafi hada da Thin-Wall Mutu Wasa,Hot Chamber Mutu Wasa,Cold Chamber Mutu Wasa), Zagaye Sabis (Mutuwar 'Yan Wasa,CNC machining,Motsa Motsa, Jiyya na sama) .Adadin al'ada Aluminium ya mutu, magnesium ko Zamak / zinc mutu simintin gyare-gyare da sauran buƙatun simintin maraba don tuntube mu.

Karkashin kulawar ISO9001 da TS 16949, Ana aiwatar da dukkan matakai ta hanyar daruruwan injunan jefa simintin da suka mutu, injunan axis 5, da sauran kayan aiki, tun daga masu fashewa zuwa na’urar Ultra Sonic masu wanki.Minghe ba kawai tana da kayan aiki na zamani ba amma kuma tana da kwararru ƙungiyar ƙwararrun injiniyoyi, masu aiki da sufetoci don tabbatar da ƙirar abokin ciniki ta zama gaskiya.

Manufactureran kwangilar masana'antar mutu. Abubuwan haɓakawa sun haɗa da sassan sanyi na sassan mutuɗar aluminum daga 0.15 lbs. zuwa 6 lbs., saurin canje-canje da aka saita, da aikin inji. Sabis-ƙarin ayyuka sun haɗa da gogewa, faɗakarwa, lalatawa, fashewar harbi, zane, zane, rufi, haɗuwa, da kayan aiki. Abubuwan da aka yi aiki tare sun haɗa da allo irin su 360, 380, 383, da 413.

Zinc ya mutu don jefa ƙirar ƙira / sabis na injiniya tare. Custom manufacturer na daidaici tutiya mutu simintin gyaran kafa. Castananan 'yan simintin gyare-gyare, pressurean ƙwanƙwasa masu juzu'in juzu'in simintin gyare-gyaren juzu'ai, ƙera simintin gyare-gyare na al'ada, ɓangaren mutu da' yan wasa masu mutuwa masu zaman kansu da ƙofar da aka hatimce za a iya ƙera su. Za'a iya kerarrar 'yan simintin a tsayi da faɗi har zuwa 24 a ciki. A cikin +/- 0.0005 a cikin. Haƙuri.

ISO 9001: 2015 bokan masana'anta ta mutu magnesium, Abubuwan haɓaka sun haɗa da matsin lamba na magnesium mai matsi mai yawa har zuwa tan 200 mai ɗumi mai zafi & 3000 ton mai sanyi, ƙirar kayan aiki, gogewa, gyare-gyaren, inji, foda & zanen ruwa, cikakken QA tare da damar CMM , taro, marufi & isarwa.

ITAF16949 bokan. Servicearin Sabis ɗin Gyare Hadawa zuba jari,yashi,Kushin nauyi, Stauren ɓoye ɓoye,Siffar Centrifugal,Cast Vacuum,Dindindin Mould Gyare, .Hanyoyin iyawa sun hada da EDI, taimakon injiniya, ingantaccen samfuri da aiki na sakandare.

Fitar Masana'antu Abubuwan Nazarin sassa don: Motoci, Bikes, Jirgin sama, kayan kiɗa, Jirgin ruwa, Na'urorin hangen nesa, na'urori masu auna sigina, na'urori masu auna sigina, Na'urori, Kayan lantarki, ,unshi, Clocks, Inji, Injiniya, Kayan Kaya, Kayan Jiki, Jigs, Telecom, Haske, Kayan aikin likita, Na'urar daukar hoto, Robobi, Sassaka, kayan sauti, kayan wasanni, Kayan aiki, Kayan wasa da ƙari.

Me Zamu taimake ku yi gaba?

Je zuwa Shafin Farko Don Mutu Wasa China

→Sassan Kasuwanci-Gano abin da muka aikata.

→ Tallan kwankwasiyya Game da Ayyukan Gyare Mutuwa

By Minghe Mutu Wasa Wasa | Categories: Labarai masu Taimakawa |Material Tags: Gyare Aluminum, Zinc Gyare, Fitar Magnesium, Castan Wasanni, Bakin Karfe Cast, Fitar tagulla,Gyare Tagulla,Fitar Bidiyo,Tarihin Kamfanin,Aluminum Mutu Gyare | Comments Off