Cikakken Cikakken Matsayi Don Karɓar Mould

Siffar Samfurin Siffar, Girman, Fit

- Ba a ba da lahani a saman samfurin ba: rashin kayan, ƙonewa, farar fata, farar layi, ƙwanƙwasawa, ɓoyayyiya, farar fata (ko fashewa, fashewa), yin burodi, da wrinkles.

- Alamar Weld: Gabaɗaya, tsawon alamar walƙiya madauwari ba ta wuce 5mm, kuma tsawon alamar walƙiya mai siffa ta musamman ba ta wuce 15mm ba, kuma ƙarfin alamar walda na iya wuce gwajin aminci na aiki.

- Ƙuntatawa: Ba a yarda da raguwa a wuraren bayyanannun bayyanar ba, kuma an yarda da ƙanƙantar da kai a wuraren da ba a sani ba (babu lahani a hannu).

- Gabaɗaya, lalatattun ƙananan samfuran bai wuce 0.3mm ba. Idan akwai buƙatun taro, dole ne a tabbatar da buƙatun taron.

- Bai kamata a sami layukan iska ko furanni na kayan a bayyane ba, kuma samfur ɗin gabaɗaya baya da kumfar iska.

- Siffar geometric da daidaiton girma na samfurin yakamata ya cika buƙatun hukuma da ingantaccen zanen ƙirar (ko fayil na 3D). Haƙurin samfuran yakamata ya kasance bisa ƙa'idar haƙuri. Haƙurin girman shaft shine haƙuri mara kyau, kuma haƙurin girman rami shine haƙuri mai kyau. Abokan ciniki suna da yadda ake buƙata, kamar yadda ake buƙata.

- Kaurin bangon samfur: Ana buƙatar kaurin bangon samfur don zama matsakaicin katanga, kaurin bangon da ba matsakaici ba yakamata ya cika buƙatun zane, kuma haƙuri ya zama -0.1mm gwargwadon halayen ƙirar.

- Haɗin samfur: harsashin farfajiya da ƙasan ƙasa sun yi daidai-ƙirar ƙasa ƙasa da 0.1mm, kuma bai kamata a yi karcewa ba. Ramin, shafuka da saman da ke da buƙatun dacewa dole ne su tabbatar da tazara mai dacewa da buƙatun amfani.

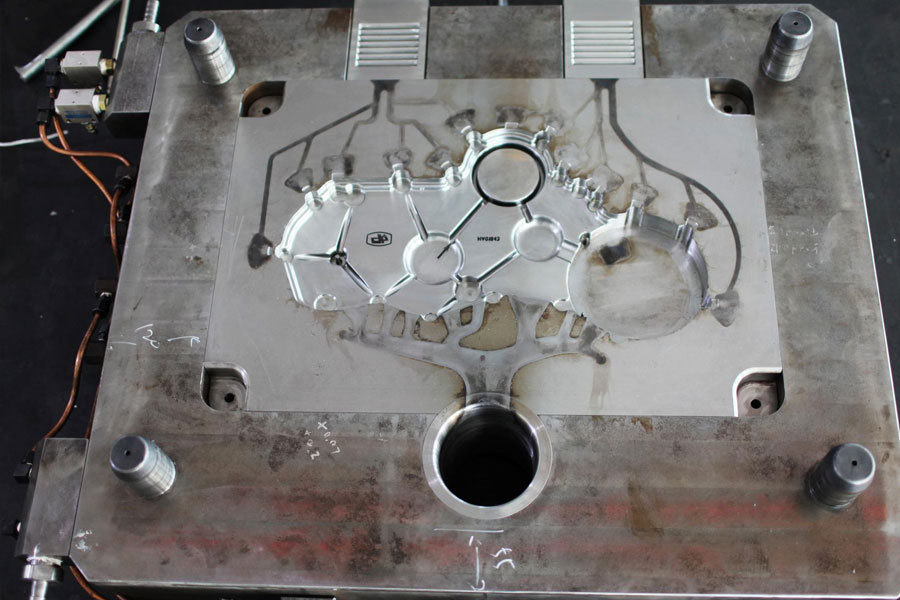

Bayyanar Mould

- 1. Alamar sunan ƙirar ta cika, haruffan a bayyane suke, kuma tsari yana da kyau.

- 2. Yakamata a gyara sunan sunan akan ƙafar ƙafa kusa da samfuri da kusurwar tunani. Alamar suna amintacciya ce kuma ba mai sauƙin cirewa ba.

- 3. Yakamata a sanya bututun ruwa mai sanyaya ruwa daga toshe filastik, idan abokin ciniki yana da wasu buƙatu, da fatan za a bi buƙatun.

- 4. Maɓallin ruwan sanyaya bai kamata ya fito daga farfajiyar tushe ba.

- 5. Ana buƙatar sarrafa bututun ruwa mai sanyaya ruwa tare da katako, madaidaicin madaidaicin shine 25mm, 30mm, 35mm ƙayyadaddun abubuwa guda uku, madaidaicin wuri yana ƙonewa, yakamata ya zama ɗaya.

- 6. Maɓallin ruwan sanyaya ya kamata ya sami alamun shiga da fita.

- 7. Alama haruffa da lambobi na Ingilishi yakamata su fi 5 girma.

- 8. Matsayin shine 10mm kai tsaye a ƙarƙashin famfo, kuma rubutun yakamata ya zama bayyananne, kyakkyawa, tsaftatacce kuma daidai gwargwado.

- 9. Kayan kwalliyar kayan kwalliya kada su shafar kwalliya da adana kayan kwalliya. Yayin shigarwa, akwai silinda masu fallasa, famfo, kayan sake saiti, da sauransu, waɗanda ya kamata a kiyaye su ta hanyar tallafar ƙafafu.

- 10. Dole ne a gyara shigar da ƙafar goyan baya akan gindin sifa tare da dunƙule da ke wucewa ta hanyar goyan bayan, kuma za a iya ɗaure ƙafar goyan bayan da ta wuce kima zuwa tushe mai ƙyalli tare da shafi mai zaren waje.

- 11. Girman ramin ejector na ƙirar ya kamata ya cika buƙatun na'urar da aka ƙayyade da allura. Ban da ƙananan ƙwayoyi, cibiyar ɗaya ba za a iya amfani da ita don fitarwa ba.

- 12. Yakamata zoben sanyawa ya zama abin dogaro. A diamita na zobe ne 100mm da 250mm. Zoben sanyawa ya fi 10-20mm girma sama da farantin ƙasa. Sai dai idan kwastomomi sun nema.

- 13. Matsakaicin waje na kayan kwalliyar yakamata ya cika bukatun injin da aka sanya masa allura.

- 14. Don ƙere -ƙere tare da buƙatun daidaitawa, yakamata a yi amfani da kibiya don nuna alamar shigarwa akan samfuri na gaba ko na baya, kuma yakamata a sami "UP" kusa da kibiya. Kibiya da rubutu duk rawaya ne, kuma tsayin rubutun shine 50mm.

- 15. Farfajiyar ginshiƙin ya kamata ba ta da rami, alamun tsatsa, zoben da ba su da yawa, tururin ruwa a ciki da waje, ramin mai, da sauransu, da lahani waɗanda ke shafar bayyanar.

- 16. Kambu ya zama mai saukin hawa da hawa. Ba za a tarwatsa sassan mold ba yayin ɗagawa. Ringsaukaka zoben dagawa ba za ta tsoma baki tare da bututun mai, silin mai ba, sandunan da aka sake saita su, da dai sauransu.

Mould Material Kuma Taurin

- 1. Tushen kwandon ya kamata ya zama madaidaicin madaurin da ya dace da ƙa'idar.

- 2. Mould forming parts and gating system (cores, movable and fix mold inserts, m inserts, disse cones, tura sanduna, sprue sleeves) an yi su da kayan aiki tare da aiki sama da 40Cr.

- 3. Lokacin gyaran filastik mai saukin lalacewa ga kwandon, yakamata sassan da aka ƙera su kasance daga kayan da ba za su iya jurewa ba, ko farfajiyar za ta ɗauki matakan kariya.

- 4. Taurin sassan da aka ƙera bai kamata ya zama ƙasa da 50HRC ba, ko kuma taurin farfajiyar farfajiyar ƙasa ya zama sama da 600HV.

Mould Out, Sake saitawa, Cire Maɓalli, Shiga Bangaren

- 1. Fitar ya zama mai santsi, ba tare da matsi ba, kuma ba tare da sauti mara kyau ba.

- 2. Ya kamata saman saman da aka karkata ya goge, kuma saman da aka karkata ya kasa da ainihin farfajiyar.

- 3. Yakamata a samar da sassan zamiya tare da ramukan mai, kuma ana buƙatar nitrided, kuma taurin bayan bayan magani shine HV700 ko sama da haka.

- 4. Duk sandunan ejector yakamata su sami matsayin juyawa na juyawa, kuma kowane lambar ejector yakamata a yi lamba.

- 5. Ya kamata a iyakance nisan fitarwar ta hanyar toshe iyaka.

- 6. Ya kamata a yi amfani da daidaitattun sassa don bazarar dawowa, kuma ƙarshen ƙarshen bazara bai kamata a goge ko yanke shi ba.

- 7. Mai zamewa da jan hankali yakamata ya kasance yana da iyakar bugun jini, kuma ƙaramin darjewa yana iyakance ta bazara. Lokacin bazara ba shi da dacewa don shigarwa, ana iya amfani da dunƙule mai ruɓi; gindin silinda dole ne ya kasance mai sauyawa.

- 8. Maɓallin zamewa mai jan hankali gabaɗaya yana ɗaukar matsayi na jagora, kuma kusurwar madaidaicin jagorar jagora yakamata ya zama 2 ° -3 ° karami fiye da kusurwar saman kullewar darjewa. Idan bugun darjewa ya yi tsayi, yakamata a yi amfani da silin mai don zane.

- 9. Lokacin da aka rufe ƙarshen ƙarshen ɓangaren da ke haifar da silinda, silinda ya kamata a sanye shi da injin kulle kansa.

- 10. Yakamata a sami farantin da zai iya sawa a ƙarƙashin babban zamewar tare da faɗin faɗin fiye da 150mm. Kayan farantin da zai iya sawa ya zama T8A. Bayan maganin zafi, taurin shine HRC50-55. Farantin lalacewa yana da girman 0.05-0.1mm fiye da babban farfajiya.

- 11. Kada sandar ejector ta motsa sama da kasa.

- 12. barara sandunan akan sandar sama, kuma alkiblar sandunan ya zama daidai, ta yadda sandunan suna da sauƙin cirewa daga samfurin.

- 13. Kwatancen da ya dace tsakanin ramin fil ɗin ejector da fil na ejector, tsawon sashin sealing, da kaurin farfajiyar ramin fil ɗin ejector yakamata ya kasance daidai da buƙatun ƙa'idodin kamfani masu dacewa.

- 14. Samfurin ya zama mai dacewa ga mai aiki don cire shi.

- 15. Lokacin da aka fitar da samfurin, yana da sauƙi a bi saman karkata, kuma ya kamata a dunƙule saman sandar ko kuma a ɗaura ta.

- 16. Babban katangar da aka kafe akan sanda ta sama yakamata ya zama abin dogaro kuma abin dogaro, yakamata a sarrafa sassan da ba a kewayen da'irar tare da gangara 3 ° -5 °, kuma yakamata a haɗa ƙananan gefen.

- 17. Kada a sami rarar baƙin ƙarfe a cikin ramin rarar mai a kan ginshiƙin juji.

- 18. facearshen fuskar komowar komo yana kwance kuma babu walda mai tabo. Babu kwantena a ƙasan kan amfrayo, walda tabo.

- 19. plateofar falon farantin farantin roba mai fa'ida daidai, kuma farantin ƙofar yana da sauƙi a buɗe.

- 20. Yakamata a tsara sandunan iyakoki masu ƙwananti uku a bangarorin biyu na shugabantar shigar da ƙirar, ko kuma a ɗora faranti a ginshiƙan don ƙirƙirar sandunan iyaka daga tsoma baki tare da mai aiki.

- 21. Yankin mai da wucewar iska ya zama santsi, kuma ya kamata a sake dawo da hidimar lantarki.

- 22. Ƙasan hannun riga mai jagora yakamata ya sami tashar fitarwa.

- 23. Bai kamata a sami rata ba a cikin shigar da fil.

Tsarin Sanyi Da Dumama

- 1. Tsarin sanyaya ko dumama yakamata a cire shi gaba ɗaya.

- 2. Ya kamata hatimin ya zama abin dogaro, tsarin bai kamata ya shiga ƙarƙashin matsin lamba na 0.5MPa ba, kuma yana da sauƙin gyarawa

- 3. Girman da siffar rami na hatimi da aka buɗe akan ginshiƙin yakamata ya cika buƙatun ƙa'idodin da suka dace.

- 4. Ya kamata a shafa man shafawa a zoben hatimi lokacin da aka sanya shi, kuma ya zama ya fi sama da saman ginshiƙin bayan an sanya shi.

- 5. Ya kamata a sanya masu raba tashan kwararar ruwa da mai ta kayan da ba sa saurin lalacewa.

- 6. Kamfanoni na gaba da na baya yakamata suyi amfani da hanyar samar da ruwa ta tsakiya.

Tsarin Gating

- 1. Saitin ƙofar bai kamata ya shafi bayyanar samfurin ba kuma ya gamsar da taron samfur.

- 2. Ya kamata a tsara sashin masu tsere da tsayi yadda ya kamata, kuma ya kamata a taqaita aikin gwargwadon yadda zai yiwu a qarqashin tabbatar da ingancin samuwar, kuma ya kamata a rage yanki na giciye don taqaita lokacin cikawa da sanyaya lokaci. A lokaci guda, asarar filastik na tsarin zubowa ya zama mafi ƙarancin.

- 3. Bangaren giciye na madogara mai faranti uku a bayan faranti na gaba ya zama trapezoidal ko semicircular.

- 4. Mota mai farantin karfe uku yana da abin fashewa a kan farantin ƙofar, diamita na ƙofar mai gudu yakamata ya zama ƙasa da 3mm, kuma ƙwallon yana da zurfin zurfin 3mm da aka shiga cikin farantin ƙofar.

- 5. Yakamata sandar jan ƙwallo ta ƙare a dogara, za a iya matse shi a ƙarƙashin zobe mai sanyawa, za a iya gyara shi da dunƙule mara kan kai, ko za a iya matsa shi da farantin matsi

- 6. atesofar ƙofa da masu gudu ya kamata a sarrafa su gwargwadon girman buƙatun zane, kuma ba a yarda da nika da injin goge ba.

- 7. Ƙofar batu yakamata ta kasance daidai da buƙatun ƙayyadewa.

- 8. Yakamata a sami kari a karshen karshen mai gudu a matsayin ramin sulke mai sanyi.

- 9. Zaɓin juzu'in Z-mai jujjuya na sandar jan yakamata ya sami canji mai santsi.

- 10. Mai gudu a farfajiya ya kamata ya zama zagaye, kuma kada a yi siraɗi na gaba da na baya.

- 11. Theofar latent a kan sandar ejector ba ta da ƙanƙancewar fuska.

- 12. Da diamita da zurfin ramin kayan sanyi don samfuran samfuri yakamata ya cika ƙa'idodin ƙira.

- 13. Maƙallan yana da sauƙin cirewa, babu alamar ƙofa akan bayyanar samfurin, kuma babu sauran ragowar a taron samfuran.

- 14. Tare da lanƙwasa ƙugiya ƙofar latent, ɓangarorin biyu na saka ya kamata a nitrided, kuma taurin saman zai iya kaiwa HV700.

Sashe na Gyarawa, Surface Parting, Exhaust Groove

- 1. Kada a sami rashin daidaito, ramuka, tsatsa da sauran lahani da suka shafi bayyanar a farfajiyar gaban da na baya.

- 2. An saka abin da aka saka tare da firam ɗin ƙirar, kuma yakamata a sami rata na ƙasa da 1mm a kewayen kusurwoyi.

- 3. Wurin rabuwa ana kiyaye shi da tsabta. Babu wata abin hawa mai niƙa don guje wa iska, kuma ɓangaren hatimin ba shi da hakora.

- 4. Zurfin dusar sharar ya zama ƙasa da ƙimar ambaliyar filastik.

- 5. Bincike da rarraba abubuwan da ake sakawa ya kamata su kasance a wuri, tare da sanya mai sassauci da amintaccen matsayi.

- 6. Abubuwan da aka saka, abubuwan sakawa, da sauransu yakamata a sanya su amintattu kuma a gyara su, yakamata a hana juzu'in juzu'in juyawa, kuma kada a sami jan ƙarfe ko ƙarfe a ƙarƙashin abin da aka saka.

- 7. endarshen fuskar sandar ejector daidai yake da ainihin.

- 8. Bangaren da yake samarwa na gaba da na baya ba shi da wata nakasa kamar ta karkashin kasa da kuma kayan kwalliya.

- 9. Ya kamata a tura haƙarƙarin haƙarƙarin cikin sauƙi.

- 10. Don samfura masu sifofi da yawa, ɓangarorin hagu da dama suna daidaita, kuma L ko R ya kamata a nuna. Idan abokin ciniki yana da buƙatun matsayi da girman, yakamata ya cika buƙatun abokin ciniki. Gabaɗaya, ƙara shi a inda bai shafi bayyanar da taro ba, kuma girman font shine 1/8.

- 11. Farfajiyar murdadden ginshiƙin yakamata ta kasance, kuma ya kamata a taɓa fiye da 75% na yankin.

- 12. Yakamata a shirya sandar fitar da kaya kusa da bangon gefen kuma kusa da haƙarƙari da maƙera, kuma ya kamata a yi amfani da sandar da ta fi girma.

- 13. Yakamata a nuna lambobin 1, 2, 3, da dai sauransu don ɓangarorin guda ɗaya.

- 14. Kowane farfajiyar tuntube, farfajiyar shiga, da kuma bangaren rabuwar ya kamata ayi bincike a kuma daidaita su a wurin.

- 15. Bangaren sealing wurin rufewa yakamata ya cika ƙa'idodin ƙira. 10-20mm don matsakaicin matsakaici da 30-50mm don manyan sikeli, kuma sauran sassan ana kera su don guje wa wuraren da babu kowa.

- 16. Fatar fata da yashi yakamata su cika buƙatun abokin ciniki daidai.

- 17. Don samfuran da ke da buƙatu don bayyana, sukurorin da ke kan samfuran ya kamata su sami matakan kariya.

- 18. Yakamata a yi amfani da bututu masu kaɗawa don ginshiƙan dunƙule tare da zurfin fiye da 20mm.

- 19. Kaurin bangon samfur ya zama daidai, kuma yakamata a sarrafa karkacewa a ƙasa ± 0.15mm.

- 20. Faɗin haƙarƙarin ya zama ƙasa da 60% na kaurin bangon saman waje.

- 21. Mahimman abubuwan da ake sakawa akan rufin karkata kuma darjewa yakamata ya sami ingantacciyar hanyar gyarawa.

- 22. An saka kwandon gaba a cikin kwandon baya ko kuma na gaba an saka shi a gaba. Wajibi ne a kulle abubuwan da ke da karko kuma a sarrafa su don guje wa iska.

Allurar Molding Production Process

- 1. Tsarin yakamata ya sami kwanciyar hankali na samar da allurar allura da maimaitawa na daidaita saitin tsari a cikin kewayon yanayin sarrafa allurar al'ada.

- 2. Matsawar allura yayin samarwa da ke sarrafa allura gabaɗaya ya zama ƙasa da 85% na matsakaicin matsakaicin matsin lamba na injin allura.

- 3. Saurin allura na injin a lokacin samar da allurar allura, saurin allurar bugun jini na kwata-kwata ba kasa da 10% na ƙimar matsakaicin allurar da aka ƙera ko fiye da 90% na ƙimar matsakaicin matsakaicin allura.

- 4. Matsayin riƙewa yayin samar da allura yakamata ya zama ƙasa da 85% na ainihin matsakaicin matsin lamba.

- 5. Ƙarfin ƙwanƙwasa yayin samar da allurar allura ya kamata ya zama ƙasa da 90% na ƙimar da aka ƙaddara na ƙirar da ta dace.

- 6. Yayin aikin samar da allura, allurar da bututun ƙarfe ya kamata a fitar cikin sauƙi kuma cikin aminci (lokaci bai wuce dakika 2 kowannensu ba).

- 7. Don kayan kwalliya tare da abun sakawa, abubuwan sakawa suna da sauƙin shigarwa kuma an gyara abubuwan da ake sakawa cikin aminci yayin samarwa.

Shigarwa Da Jirgin Sama

- 1. Ya kamata a tsabtace ramin da aka ƙera kuma a fesa shi da man ƙwari.

- 2. Ya kamata a rufe sassan zamiya da man shafawa.

- 3. Ya kamata a rufe mashigar ruwa ta sprue da man shafawa.

- 4. Ya kamata a tsara kayan kwalliyar tare da matattarar abubuwa, kuma bayanai dalla-dalla sun dace da ƙirar ƙira.

- 5. Bangaren sassa da suturar sutura ya zama cikakke, tare da cikakken jeri da sunan mai siyarwa.

- 6. Yakamata a ɗauki matakan rufewa don hana ƙwayoyin cuta shiga cikin ruwan kwandon, ruwa, gas, da mashigin lantarki da kanti.

- 7. Fesa fenti a farfajiyar farfajiyar, kamar yadda mai bukata ya bukata.

- 8. Ya kamata a narka da dusar ƙanƙara tare da danshi-danshi, ruwa-hujja da fakitin faɗa, kuma abokan ciniki suna da buƙatun gwargwadon buƙatunsu.

- 9. Zane -zanen samfur, zane -zanen tsari, zane -zane da tsarin dumama, zane mai gudana mai zafi, kayan gyara da cikakkun bayanai na mai siyar da kayan, umarnin aiki, rahoton gwajin mold, takaddar duba masana'anta, da takaddun lantarki yakamata su cika.

Da fatan za a adana tushe da adireshin wannan labarin don sake bugawa: Cikakken Cikakken Matsayi Don Karɓar Mould

Minghe Gyare Company aka sadaukar domin tsirar da kuma samar da inganci da high yi Gyare sassa (karfe mutu simintin sassa Range yafi hada da Thin-Wall Mutu Wasa,Hot Chamber Mutu Wasa,Cold Chamber Mutu Wasa), Zagaye Sabis (Mutuwar 'Yan Wasa,CNC machining,Motsa Motsa, Jiyya na sama) .Adadin al'ada Aluminium ya mutu, magnesium ko Zamak / zinc mutu simintin gyare-gyare da sauran buƙatun simintin maraba don tuntube mu.

Karkashin kulawar ISO9001 da TS 16949, Ana aiwatar da dukkan matakai ta hanyar daruruwan injunan jefa simintin da suka mutu, injunan axis 5, da sauran kayan aiki, tun daga masu fashewa zuwa na’urar Ultra Sonic masu wanki.Minghe ba kawai tana da kayan aiki na zamani ba amma kuma tana da kwararru ƙungiyar ƙwararrun injiniyoyi, masu aiki da sufetoci don tabbatar da ƙirar abokin ciniki ta zama gaskiya.

Manufactureran kwangilar masana'antar mutu. Abubuwan haɓakawa sun haɗa da sassan sanyi na sassan mutuɗar aluminum daga 0.15 lbs. zuwa 6 lbs., saurin canje-canje da aka saita, da aikin inji. Sabis-ƙarin ayyuka sun haɗa da gogewa, faɗakarwa, lalatawa, fashewar harbi, zane, zane, rufi, haɗuwa, da kayan aiki. Abubuwan da aka yi aiki tare sun haɗa da allo irin su 360, 380, 383, da 413.

Zinc ya mutu don jefa ƙirar ƙira / sabis na injiniya tare. Custom manufacturer na daidaici tutiya mutu simintin gyaran kafa. Castananan 'yan simintin gyare-gyare, pressurean ƙwanƙwasa masu juzu'in juzu'in simintin gyare-gyaren juzu'ai, ƙera simintin gyare-gyare na al'ada, ɓangaren mutu da' yan wasa masu mutuwa masu zaman kansu da ƙofar da aka hatimce za a iya ƙera su. Za'a iya kerarrar 'yan simintin a tsayi da faɗi har zuwa 24 a ciki. A cikin +/- 0.0005 a cikin. Haƙuri.

ISO 9001: 2015 bokan masana'anta ta mutu magnesium, Abubuwan haɓaka sun haɗa da matsin lamba na magnesium mai matsi mai yawa har zuwa tan 200 mai ɗumi mai zafi & 3000 ton mai sanyi, ƙirar kayan aiki, gogewa, gyare-gyaren, inji, foda & zanen ruwa, cikakken QA tare da damar CMM , taro, marufi & isarwa.

ITAF16949 bokan. Servicearin Sabis ɗin Gyare Hadawa zuba jari,yashi,Kushin nauyi, Stauren ɓoye ɓoye,Siffar Centrifugal,Cast Vacuum,Dindindin Mould Gyare, .Hanyoyin iyawa sun hada da EDI, taimakon injiniya, ingantaccen samfuri da aiki na sakandare.

Fitar Masana'antu Abubuwan Nazarin sassa don: Motoci, Bikes, Jirgin sama, kayan kiɗa, Jirgin ruwa, Na'urorin hangen nesa, na'urori masu auna sigina, na'urori masu auna sigina, Na'urori, Kayan lantarki, ,unshi, Clocks, Inji, Injiniya, Kayan Kaya, Kayan Jiki, Jigs, Telecom, Haske, Kayan aikin likita, Na'urar daukar hoto, Robobi, Sassaka, kayan sauti, kayan wasanni, Kayan aiki, Kayan wasa da ƙari.

Me Zamu taimake ku yi gaba?

Je zuwa Shafin Farko Don Mutu Wasa China

→Sassan Kasuwanci-Gano abin da muka aikata.

→ Tallan kwankwasiyya Game da Ayyukan Gyare Mutuwa

By Minghe Mutu Wasa Wasa | Categories: Labarai masu Taimakawa |Material Tags: Gyare Aluminum, Zinc Gyare, Fitar Magnesium, Castan Wasanni, Bakin Karfe Cast, Fitar tagulla,Gyare Tagulla,Fitar Bidiyo,Tarihin Kamfanin,Aluminum Mutu Gyare | Comments Off