Hanyar Magance Ƙaƙarar Moda A Ƙofar Fitar Ƙasa

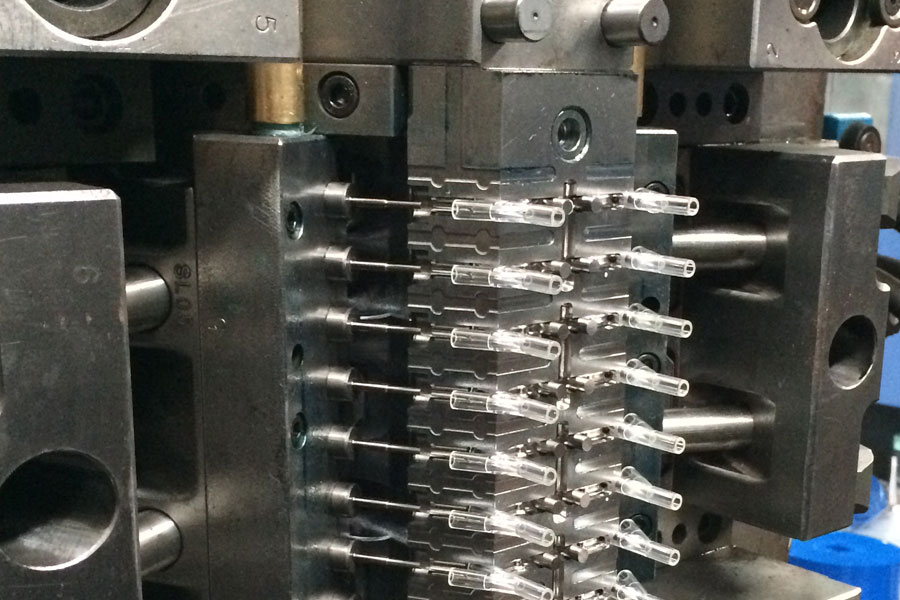

A kan aiwatar da mutu-simintin samarwa, galibi ana cin karo da cewa ƙyalli mai ƙyalli ko ƙyalli yana faruwa a ƙofar ɓangaren ƙirar. Ginin aluminium yana manne da bangon da ke kusa da ƙofar kuma ba mai sauƙin cirewa bane. Wannan yanayin yana faruwa sau da yawa a cikin sababbin kyawon tsayuwa. da yawa. Lokacin da masana'antar ta fara kera kwalaye 186, sassan ƙofar sun makale a cikin tubalan kuma fashewar ta bayyana, wanda hakan ya haifar da ƙarancin ƙimar samfur kuma yana shafar samar da simintin gyare -gyare na al'ada. Akwai dalilai da yawa waɗanda ke haifar da ƙyalli, kamar ƙirar sinadaran da ba a cancanta ba na ƙarfe, saboda ƙarfe na ƙarfe da baƙin ƙarfe suna da dangantaka mai ƙarfi, a ƙarƙashin wasu yanayi, yana da sauƙin amsawa tare da ƙirar H13 kuma yana haifar da liƙa; yin amfani da wakilan sakin kwandon ba shi da kyau Tsarin tsarin sigogi ba shi da ma'ana; ƙirar ƙofar ƙirar ba ta da ma'ana; rashin ƙarfi ko kazantar farfajiyar ƙirar bai isa ba, da sauransu, waɗanda ke buƙatar warwarewa a cikin takamaiman tsarin samarwa. Bayan bincike da taƙaitawa: Mun ɗauki waɗannan matakan don magance matsalar mannewa da fasa a ƙofar akwatin 186.

1. Tattaunawar sinadaran sinadarin aluminium

Aluminum gami da baƙin ƙarfe suna da dangantaka mai ƙarfi. Lokacin da abun cikin baƙin ƙarfe a cikin gami na aluminium bai wuce 0.7%ba, ƙirar aluminium yana da sauƙin amsawa ta hanyar sunadarai tare da ƙirar H13 don samar da mahadi, waɗanda ke bin farfajiyar ƙirar kuma suna samar da molds, amma baƙin ƙarfe na iya Rage halayen aluminium. su manne da kyawon tsayuwa da sauƙaƙe mutuƙar simintin. Tare da ƙaruwar abun cikin ƙarfe, kaddarorin injin suna raguwa, musamman tasirin taurin da raguwar filastik, yanayin fashewar zafi yana ƙaruwa, kuma tabo masu wuya suna bayyana a cikin gami na aluminium, kuma aikin sarrafawa ya lalace. Sabili da haka, abun cikin ƙarfe a cikin allurar aluminium da aka jefa yakamata a sarrafa shi tsakanin 0.7%~ 1.3%.

Sabili da haka, ya kamata mu fara nazarin abubuwan da ke cikin sinadarin ƙarfe na aluminium. Bayan nazarin bakan, abun ƙarfe na ADC12 alloy aluminium da aka yi amfani da shi a cikin wannan samfurin kusan 0.9%, kuma babu matsala tare da abun da aka haɗa.

2. Daidaita sigogin aiwatar da simintin gyare -gyare

Saitin sigogi na aiwatarwa shima yana da babban tasiri akan ƙirar mai ɗorawa, kamar matsin lamba da saurin, zazzabi mai ƙarar allo, zazzabi na ƙirar, da sauransu, don haka dole ne a kirga sigogi masu dacewa daidai gwargwado amfani da buƙatun simintin.

- Daidaita matsin lamba da sauri. Haɓakar matsin lamba na ƙarfe zai haɓaka haɗin gwiwa tsakanin gami da ƙirar, kuma zafin gogayya tsakanin ƙarfe daban -daban a ƙarƙashin matsin lamba yana sanya walda tsakanin ƙarfe, wanda shima lamari ne mai ɗorewa. Ana buƙatar lissafin matsin kwararar ƙarfe kuma saita ƙaramin matsin lamba da ake buƙata don samar da samfuran simintin inganci. An samar da wannan samfurin a ƙarƙashin samfurin Lijin DCC1600. Dangane da buƙatun samfuran, ana lissafin matsin lambar haɓaka da ake buƙata don zama 24 ~ 26Mpa don gujewa haɗuwar ƙarfe a ƙarƙashin matsanancin matsin lamba da rage matsin lamba, wanda kuma za'a iya guje masa. Faruwar fasa. Gudun ƙarfe mai saurin gudu ya mamaye bango mai siffa, ƙirar da aka yi ta mutu-mutu ta tsufa, kuma ƙirar ƙarfe mai sauri ta shiga bangon mai siffa a cikin yanayin hazo, ya manne akan ƙirar, kuma ba zai iya haɗawa da m karfe kwarara don samar surface lahani. Matsa da sauri abubuwa biyu ne da ke taimakon juna da takurawa juna. Domin saduwa da buƙatun fasaha na simintin gyare -gyare, dole ne a daidaita matsa lamba da saurin cika simintin gyare -gyare.

- Sarrafa mold da alloy zazzabi. Matsayin zafin zafin jiki yana da matukar mahimmanci ga ko ƙuƙwalwar ƙirar tana faruwa. A mafi girma da zazzabi mold, da sauki shi ne don samar da m kyawon tsayuwa. Shigar da ruwa na kwandon shine babban yankin zafin jiki. A cikin wannan yanki, yakamata mu ƙara adadin bututun jan ƙarfe da aka fesa, ko amfani da bindiga mai fesawa don kwantar da ɓangaren ƙirar, da bincika tasirin ruwan sanyaya na ƙirar. A cikin tsarin samarwa na ainihi, zamu iya amfani da infrared Thermometer yana gano sashin madogarar kuma yana sarrafa zafin zazzabi tsakanin 150 ° C da 220 ° C don ba da damar ƙirar ta isa ma'aunin zafi. An saita zafin gami na aluminium zuwa mafi ƙasƙanci gwargwadon buƙatun simintin gyare -gyare, tsakanin 610 ℃ ~ 680 ℃, don rage samuwar molds.

- Ta hanyar debugging na sama tsari. Gyaran da ke manne a ƙofar yana samun sauƙi har zuwa wani ɗan lokaci, amma har yanzu yana da tsayayye kuma ya fi birgewa. Don haka mun fara inganta mai gudu na mold. Babban ƙofar cikin gida yana ƙara yawan zafin jiki na ƙirar gida lokacin da kwararar ƙarfe ke shafar bangon mai siffa kuma yana hanzarta samuwar kwandon shara. Don haka, ya zama dole a yi la’akari da rage saurin ƙofar ciki. Gudun ƙofar ciki = saurin allura * yanki naushi / yanki. Ana iya gani daga dabarar cewa rage saurin ƙofar ciki na iya haɓaka yankin giciye na zubar da ciki, rage saurin allura kuma Sauya ɗakin matsa lamba. Muna haɓaka yankin giciye na zub da ciki da daidaita saurin allura don rage saurin ƙofar ciki da rage samuwar kwandon shara.

Mai tseren akwatin 186 yana ɗaukar ƙofar ciki. Tasirin kai tsaye na kwararar ƙarfe akan farfajiyar ƙirar na iya lalata fim ɗin ƙarfe oxide mai kauri akan farfajiyar, yana sa saman murfin ya zama mara daidaituwa kuma yana sa ƙirar ta manne. Ta hanyar gyara mai gudu don sanya kwararar ƙarfe ta tuntuɓi farfajiyar rami a ƙaramin kusurwa, yana yiwuwa kuma a yi amfani da madauwari arc akan mai gudu.

3. Amfani da wakilin saki

Wakilin sakin ƙirar yana taimakawa rage ƙyalli. Wajibi ne a yi amfani da wakili mai ƙyalli mai kyau. Wakilin sakin ƙirar zai iya samar da fim mai kariya tsakanin simintin gyare -gyare da ƙirar don hana miyar miyar ta tuntuɓi madarar kai tsaye don hana ƙulli. Ko a saman farfajiya mai ƙyalli, lokacin da aka auna ta cikin micrometers, ana iya ganin wurare da yawa marasa daidaituwa. Wakilin sakin ya cika wannan rashin daidaituwa kuma yana haifar da tasirin mai, amma za a wanke wakilin sakin a ƙarƙashin aikin kwararar vortex na narkakken ƙarfe don samar da kwandon shara. Kyakkyawan wakili dole ne ya sami isasshen ƙarfi don tsayayya da rabuwa ko tasirin ƙarfe mai narkewa. Zazzabi mai sanyaya ruwa na ƙirar yakamata ya zama ƙasa da zafin zafin farfajiyar ƙirar, don wakilin sakin zai iya kasancewa a haɗe da farfajiyar ƙirar kuma ya taka rawar kariya. Idan zafin jiki na ƙirar ya yi yawa, wakilin sakin zai zama da wahala a manne da farfajiyar ƙirar. Wannan saboda wakilin da za a saki zai yi zafi sosai zuwa zafin jiki mai yawa, ta yadda zai ƙafe da sauri kuma ba zai iya bin farfajiyar ƙirar ba, wanda ke ƙaruwa da ƙyalli na ƙyalli. Mafi kyawun zafin jiki don wakilin sakin don ƙirƙirar fim mai kariya akan farfajiyar ƙirar shine 200 ° C ~ 250 ° C. Lokacin da kwararar ƙarfe na allura ta sa farfajiyar ta yi kauri, yanayin ƙulli na ƙyalli zai ƙaru. A wurin da danko ya fi tsanani, za ku iya amfani da wasu man shafawa na musamman mai shafawa da manna sigar saki a ɓangaren ƙirar. Waɗannan samfuran duka ne Yana da kyakkyawan lubricating da demoulding sakamako kuma yana rage samuwar molds.

4. Mould surface treatment

Wasu hanyoyin jiyya na farfajiya na iya hana faruwar lamiri. Ya kamata a yi amfani da kayan musamman tare da wuraren narkewa mafi girma don magance farfajiyar ƙirar. Ana iya haɗa wannan gami da baƙin ƙarfe kuma yana iya bin matsayin farfajiyar ƙirar don gujewa mannewa. Hakanan yana yiwuwa a yi amfani da abubuwa daban -daban don hana yin liƙa a matsayi mai ƙyalli don kula da farfajiyar ƙirar, ƙara taurin kayan a saman ƙirar a yanayin zafi mai zafi, da rage ayyukan ƙirar ƙirar don gujewa tsayawa.

A Ƙarshen:

Ta hanyar daidaitawa da haɓaka abubuwa daban-daban waɗanda ke shafar kwandon shara, manne da liƙa a ƙofar an sarrafa su sosai, kuma ƙimar cancantar samfurin ta isa ga buƙatun kamfanin, yana tabbatar da samar da kayan yau da kullun.

Babban matakan kulawa:

- Tattaunawa da duba abun da ke cikin sinadarai a cikin gami na aluminium

- Rage zafin zafin jiki zuwa mafi ƙanƙanta inda ƙirar ke da saurin tsayawa

- Wakilin sakin ƙirar da samfuran saki na musamman da aka fesa akan farfajiyar ƙirar na iya rage abin da ya faru na ƙyalli.

- A ƙarƙashin yanayin tabbatar da inganci, yi ƙoƙarin rage zafin zafin ƙarfe mai narkar da shi gwargwadon iko

- Jagorancin karfen ƙarfe da ke shiga cikin ƙirar dole ne ya tuntubi saman ramin a ƙaramin kusurwa

- A ƙarƙashin cika buƙatun fasaha na simintin gyare -gyare, matsa lamba da saurin cika simintin mutuƙar dole ne a daidaita shi da ƙarfi

- Wasu hanyoyin jiyya na farfajiya na iya hana faruwar abin da ke liƙawa, ƙara taurin abu a saman farfajiyar a yanayin zafi mai zafi, da rage ayyukan farfajiyar ƙirar don gujewa daskarewa.

Da fatan za a adana tushe da adireshin wannan labarin don sake bugawa: Hanyar Magance Ƙaƙarar Moda A Ƙofar Fitar Ƙasa

Minghe Kamfanin 'Yan Wasa Masu Mutu aka sadaukar domin tsirar da samar da inganci da kuma high yi Gyare sassa (karfe mutu simintin sassa Range yafi hada da Thin-Wall Mutu Wasa,Hot Chamber Mutu Wasa,Cold Chamber Mutu Wasa), Zagaye Sabis (Mutuwar 'Yan Wasa,CNC machining,Motsa Motsa, Jiyya na sama) .Adadin al'ada Aluminium ya mutu, magnesium ko Zamak / zinc mutu simintin gyare-gyare da sauran buƙatun simintin maraba don tuntube mu.

Karkashin kulawar ISO9001 da TS 16949, Ana aiwatar da dukkan matakai ta hanyar daruruwan injunan jefa simintin da suka mutu, injunan axis 5, da sauran kayan aiki, tun daga masu fashewa zuwa na’urar Ultra Sonic masu wanki.Minghe ba kawai tana da kayan aiki na zamani ba amma kuma tana da kwararru ƙungiyar ƙwararrun injiniyoyi, masu aiki da sufetoci don tabbatar da ƙirar abokin ciniki ta zama gaskiya.

Manufactureran kwangilar masana'antar mutu. Abubuwan haɓakawa sun haɗa da sassan sanyi na sassan mutuɗar aluminum daga 0.15 lbs. zuwa 6 lbs., saurin canje-canje da aka saita, da aikin inji. Sabis-ƙarin ayyuka sun haɗa da gogewa, faɗakarwa, lalatawa, fashewar harbi, zane, zane, rufi, haɗuwa, da kayan aiki. Abubuwan da aka yi aiki tare sun haɗa da allo irin su 360, 380, 383, da 413.

Zinc ya mutu don jefa ƙirar ƙira / sabis na injiniya tare. Custom manufacturer na daidaici tutiya mutu simintin gyaran kafa. Castananan 'yan simintin gyare-gyare, pressurean ƙwanƙwasa masu juzu'in juzu'in simintin gyare-gyaren juzu'ai, ƙera simintin gyare-gyare na al'ada, ɓangaren mutu da' yan wasa masu mutuwa masu zaman kansu da ƙofar da aka hatimce za a iya ƙera su. Za'a iya kerarrar 'yan simintin a tsayi da faɗi har zuwa 24 a ciki. A cikin +/- 0.0005 a cikin. Haƙuri.

ISO 9001: 2015 bokan masana'anta ta mutu magnesium, Abubuwan haɓaka sun haɗa da matsin lamba na magnesium mai matsi mai yawa har zuwa tan 200 mai ɗumi mai zafi & 3000 ton mai sanyi, ƙirar kayan aiki, gogewa, gyare-gyaren, inji, foda & zanen ruwa, cikakken QA tare da damar CMM , taro, marufi & isarwa.

ITAF16949 bokan. Servicearin Sabis ɗin Gyare Hadawa zuba jari,yashi,Kushin nauyi, Stauren ɓoye ɓoye,Siffar Centrifugal,Cast Vacuum,Dindindin Mould Gyare, .Hanyoyin iyawa sun hada da EDI, taimakon injiniya, ingantaccen samfuri da aiki na sakandare.

Fitar Masana'antu Abubuwan Nazarin sassa don: Motoci, Bikes, Jirgin sama, kayan kiɗa, Jirgin ruwa, Na'urorin hangen nesa, na'urori masu auna sigina, na'urori masu auna sigina, Na'urori, Kayan lantarki, ,unshi, Clocks, Inji, Injiniya, Kayan Kaya, Kayan Jiki, Jigs, Telecom, Haske, Kayan aikin likita, Na'urar daukar hoto, Robobi, Sassaka, kayan sauti, kayan wasanni, Kayan aiki, Kayan wasa da ƙari.

Me Zamu taimake ku yi gaba?

Je zuwa Shafin Farko Don Mutu Wasa China

→Sassan Kasuwanci-Gano abin da muka aikata.

→ Tallan kwankwasiyya Game da Ayyukan Gyare Mutuwa

By Minghe Mutu Wasa Wasa | Categories: Labarai masu Taimakawa |Material Tags: Gyare Aluminum, Zinc Gyare, Fitar Magnesium, Castan Wasanni, Bakin Karfe Cast, Fitar tagulla,Gyare Tagulla,Fitar Bidiyo,Tarihin Kamfanin,Aluminum Mutu Gyare | Comments Off