Fasaha don rage gogewar sassan injin mota

A matsayin ma'auni don rage gogayya tsakanin sassan injin mota, ana iya raba shi cikin nau'ikan uku masu zuwa.

Oneaya shine don rage ainihin wurin tuntuɓar tsakanin abubuwa;

Na biyu shine yin ƙaramin damuwa tsakanin sassa;

Na uku shine rage nauyin shigarwa tsakanin abubuwan.

Rage kaurin sashi na sassan yana taimakawa rage ainihin hulɗa tsakanin sassan. Dangane da ba canza canjin farko na farfajiyar ba, za a iya daidaita farfajiyar kayan da za a iya haɗawa ta hanyar zamewa, wanda zai iya ƙara rage ƙarfin gogayya.

A halin yanzu, galibin injunan silinar injin ana yin su ne ta hanyar jefa gandun daji da aka yi da baƙin ƙarfe mai launin toka a cikin toshe na aluminium. Ƙarfin ƙarfe na baƙin ƙarfe (50W/(m · k)) ya yi ƙasa da na aluminium (100W/(m · k)), kaurin baƙin ƙarfe yana da yawa mm. Kwanan nan, don inganta ɓarkewar zafi a cikin ɗakin konewa, ana amfani da hannayen ƙarfe na baƙin ƙarfe maimakon buɗaɗɗen silinda, kuma ana fesa baƙin ƙarfe. Wannan na iya haɓaka sealing na keɓewa da bakin bangon bututu, wanda ke haɓaka canja wurin zafi da canja wurin zafi a wannan ɓangaren. Canja wurin zafi.

Bugu da ƙari, a matsayin sabon abu na musamman don fesawar zafin jiki, ana gabatar da wani mataki na ɓoyayyiya a cikin fim ɗin, kuma ana fallasa ɓoyayyiyar a saman farfajiyar, wanda zai iya inganta riƙewar mai na farfajiyar silinda.

Tun da ba lallai ba ne a yi amfani da raƙuman raƙuman ruwa na injin silinda na yau da kullun don tabbatar da riƙe mai, za a iya daidaita farfajiyar silinda. Baya ga fa'idodin da aka ambata a sama na kyawawan halaye na canja wurin zafi, Hakanan yana iya rage raguwa yadda yakamata daga kan iyaka zuwa yankin lubrication mai gauraye.

Dangane da hulɗar da ke tsakanin ɓarna a kan ɓarna na ɓangarorin, ana amfani da duk faɗin saman da ya haɗa da ɓarna azaman ƙaramin abin damuwa. A matsayin hanyar rage kauri da rage gogayya kadai, ana iya amfani da man shafawa mai ƙarfi.

Musamman, lokacin da matsin saman bai yi yawa ba, ana iya amfani da abin da ake kira murfi mai taushi, wato granular molybdenum disulfide (MoS2) ko graphite, da tetrafluoroethylene a matsayin daskararren man shafawa an tarwatsa su a cikin resin polyamide (PAI) a cikin matsakaici, ko murfin da aka samu ta hanyar watsawa kai tsaye MoS2 barbashi akan kayan aiki a babban gudu. Za'a iya amfani da irin wannan murfin a saman farfajiyar sandar piston da murɗaɗɗen kayan haɗin gwiwa tare da babban yankin lamba a cikin sassan injin.

A gefe guda, don ɓangarorin da ke da matsanancin matsin lamba, mun haɓaka murfin DLC wanda ke da madaidaicin ƙarancin gogewa kamar madaidaicin mai lokacin da yake da wuya kuma ba mai shafawa ba, don a sami sakamako iri ɗaya a ƙarƙashin lubrication. Shafi.

Wannan labarin zai gabatar da fim ɗin DLC wanda bai ƙunshi hydrogen (fim ɗin DLC ba tare da hydrogen ba) da fim ɗin DLC wanda ya ƙunshi Si (Si-DLC). Su biyun sun sha banban da na baya dangane da kulawar farfajiya da tunanin ƙira a cikin cewa rufin da kansa ba shi da halaye daban -daban, kuma haɗuwar mai mai ɗorawa ko danshi a cikin mai mai na iya rage ƙima sosai.

Don rage taɓarɓarewa tsakanin zoben piston da ramin silinda, a cikin 'yan shekarun nan, an yi amfani da fim ɗin CrN don maye gurbin fasahar da ta gabata ta Cr ko fasahar nitriding. Kaurin fim ɗin Cr-plated shine kusan 100, yayin da kaurin fim ɗin CrN tare da juriya mai kyau shine 25 kawai, wanda zai iya rage girman karkacewar kaurin fim. A sakamakon haka, ba tare da canza ƙananan iyakar tashin hankalin zobe na piston ba, da saita ƙimar matsakaici kawai don zama ƙarami, za a iya rage gogayya tsakanin zoben piston da silinda.

Bugu da ƙari, tun da yawan suturar fim ɗin CrN ƙarami ne, ana iya kiyaye ƙanƙarar farko na farfajiyar piston, kuma za a iya murƙushe ƙarin lamba ta hanyar sakawa, wanda kuma yana taimakawa rage raguwa.

Da fatan za a adana tushe da adireshin wannan labarin don sake bugawa: Fasaha don rage gogewar sassan injin mota

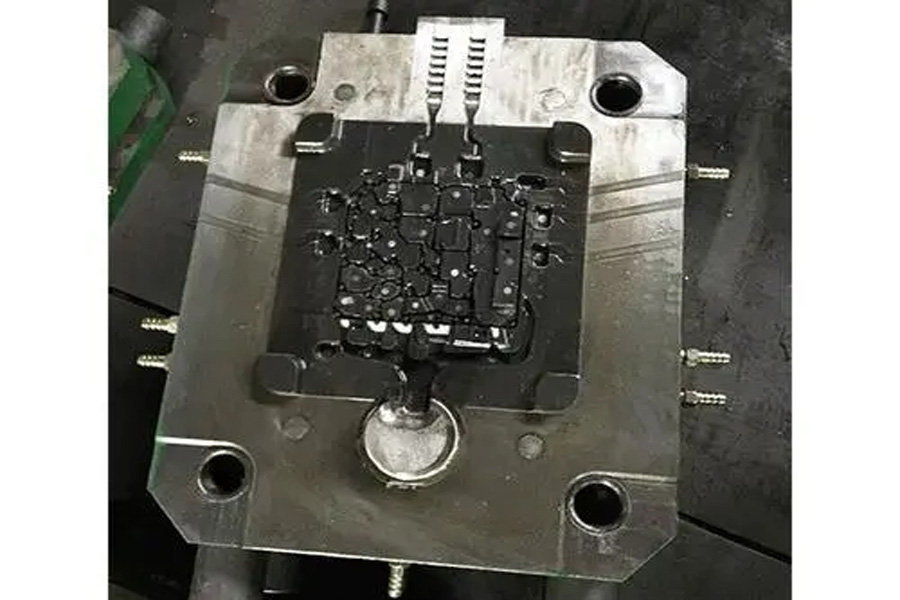

Minghe Kamfanin 'Yan Wasa Masu Mutu aka sadaukar domin tsirar da samar da inganci da kuma high yi Gyare sassa (karfe mutu simintin sassa Range yafi hada da Thin-Wall Mutu Wasa,Hot Chamber Mutu Wasa,Cold Chamber Mutu Wasa), Zagaye Sabis (Mutuwar 'Yan Wasa,CNC machining,Motsa Motsa, Jiyya na sama) .Adadin al'ada Aluminium ya mutu, magnesium ko Zamak / zinc mutu simintin gyare-gyare da sauran buƙatun simintin maraba don tuntube mu.

Karkashin kulawar ISO9001 da TS 16949, Ana aiwatar da dukkan matakai ta hanyar daruruwan injunan jefa simintin da suka mutu, injunan axis 5, da sauran kayan aiki, tun daga masu fashewa zuwa na’urar Ultra Sonic masu wanki.Minghe ba kawai tana da kayan aiki na zamani ba amma kuma tana da kwararru ƙungiyar ƙwararrun injiniyoyi, masu aiki da sufetoci don tabbatar da ƙirar abokin ciniki ta zama gaskiya.

Manufactureran kwangilar masana'antar mutu. Abubuwan haɓakawa sun haɗa da sassan sanyi na sassan mutuɗar aluminum daga 0.15 lbs. zuwa 6 lbs., saurin canje-canje da aka saita, da aikin inji. Sabis-ƙarin ayyuka sun haɗa da gogewa, faɗakarwa, lalatawa, fashewar harbi, zane, zane, rufi, haɗuwa, da kayan aiki. Abubuwan da aka yi aiki tare sun haɗa da allo irin su 360, 380, 383, da 413.

Zinc ya mutu don jefa ƙirar ƙira / sabis na injiniya tare. Custom manufacturer na daidaici tutiya mutu simintin gyaran kafa. Castananan 'yan simintin gyare-gyare, pressurean ƙwanƙwasa masu juzu'in juzu'in simintin gyare-gyaren juzu'ai, ƙera simintin gyare-gyare na al'ada, ɓangaren mutu da' yan wasa masu mutuwa masu zaman kansu da ƙofar da aka hatimce za a iya ƙera su. Za'a iya kerarrar 'yan simintin a tsayi da faɗi har zuwa 24 a ciki. A cikin +/- 0.0005 a cikin. Haƙuri.

ISO 9001: 2015 bokan masana'anta ta mutu magnesium, Abubuwan haɓaka sun haɗa da matsin lamba na magnesium mai matsi mai yawa har zuwa tan 200 mai ɗumi mai zafi & 3000 ton mai sanyi, ƙirar kayan aiki, gogewa, gyare-gyaren, inji, foda & zanen ruwa, cikakken QA tare da damar CMM , taro, marufi & isarwa.

ITAF16949 bokan. Servicearin Sabis ɗin Gyare Hadawa zuba jari,yashi,Kushin nauyi, Stauren ɓoye ɓoye,Siffar Centrifugal,Cast Vacuum,Dindindin Mould Gyare, .Hanyoyin iyawa sun hada da EDI, taimakon injiniya, ingantaccen samfuri da aiki na sakandare.

Fitar Masana'antu Abubuwan Nazarin sassa don: Motoci, Bikes, Jirgin sama, kayan kiɗa, Jirgin ruwa, Na'urorin hangen nesa, na'urori masu auna sigina, na'urori masu auna sigina, Na'urori, Kayan lantarki, ,unshi, Clocks, Inji, Injiniya, Kayan Kaya, Kayan Jiki, Jigs, Telecom, Haske, Kayan aikin likita, Na'urar daukar hoto, Robobi, Sassaka, kayan sauti, kayan wasanni, Kayan aiki, Kayan wasa da ƙari.

Me Zamu taimake ku yi gaba?

Je zuwa Shafin Farko Don Mutu Wasa China

→Sassan Kasuwanci-Gano abin da muka aikata.

→ Tallan kwankwasiyya Game da Ayyukan Gyare Mutuwa

By Minghe Mutu Wasa Wasa | Categories: Labarai masu Taimakawa |Material Tags: Gyare Aluminum, Zinc Gyare, Fitar Magnesium, Castan Wasanni, Bakin Karfe Cast, Fitar tagulla,Gyare Tagulla,Fitar Bidiyo,Tarihin Kamfanin,Aluminum Mutu Gyare | Comments Off