Ire -iren Wurare Uku Da Zuba Zuwa Ga Ductile Iron

Gabaɗaya ana amfani da yashi Furanci azaman kayan ƙira don manyan simintin ƙarfe na ƙarfe da aka samar a China. An samar da shi a cikin yanki guda, tare da nauyin zubar da nauyi da tsari mai rikitarwa. Yana da babban buƙatu akan inganci da aikin simintin gyare -gyare. Wasu lahani na simintin, musamman naƙasassun lahani, galibi suna bayyana a tsarin narkewa. Zai sa a goge simintin kuma ya haifar da manyan asarar tattalin arziƙi, musamman kayan QT400-18AR, wanda ke da babban ƙarfi, tsayi mai tsawo, da buƙatun ƙimar tasiri.

Yayin tabbatar da kaddarorin injinan irin waɗannan kauri da manyan sassa, ba abu ne mai sauƙi ba don guje wa lalatattun ruwa da ke taɓarɓarewa. Ta hanyar ƙera samfuran samfuran, an yi amfani da kayan aikin bincike na Elkem don yin nazarin tasirin sinadaran sinadarai da zub da zazzabi a kan giraf ɗin da ke iyo, kangewa da sauran lahani na madaidaicin samfurin tare da kaurin bango na 180mm. Sannan ana amfani da shi wajen samar da baƙin ƙarfe mai kauri mai katanga don samun simintin inganci mai kyau.

An shirya kayan aiki da kayan aiki don amfani da baƙin ƙarfe alade mai tsarkin kai, tsinke mai ƙarancin manganese, babban wakilin spheroidizing magnesium, 75#Inji na FeSi; Elkem low-magnesium spheroidizing wakili, inoculant; Tunan 1.5 na wutar lantarki mai narkewa na tsaka -tsaki, jakar spheroidizing 500kg, 500kg tundish. Elkem EPIC thermal analyzer, carbon da sulfur analyzer, spectrometer. Girman madaidaicin samfurin ƙirar katako shine 600mm × 400mm × 180mm, kuma an samar da tsarin gwaji. Ana amfani da kaurin bango na 180mm don rufe samfuran ƙarfe mai kauri da babba spheroidal. Yana da wakilci sosai. An sanye shi da tsarin haɓakawa da tsinkaye kuma yana ɗaukar ƙasa yana zube tare da nauyin 500kg.

An tsara shirin narkewa da zubewa don amfani da tanderun mitar tsaka -tsaki na 1.5t don narkar da baƙin ƙarfe 1.5t, 500kg a duk lokacin da ake yin allurar rigakafin cutar, da kuma zuba akwatin 1 na ƙananan samfuran gwajin samfur. An zuba jimillar akwatuna 3 na sassan gwaji a cikin tanderun 1. An tsara dabaru daban -daban na narkewa da zuba kamar haka:

Na farko tsarin cajin rabo:

85% baƙin ƙarfe alade, 15% raunin ƙarfe mai ƙarancin manganese; sarrafa abun da ke tattare da sinadarai: ɗaukar tsarin kula da inoculation na spheroidizing: da farko, ana isar da baƙin ƙarfe 500k zuwa tundish, kuma 1.3-1.5% babban-magnesium spheroidizing wakili, 0.3-0.4% inoculant da inoculant an saka su cikin jakar spheroidizing 0.8% wakili mai rufewa, invert jakar don spheroidization. Bayan an kammala aikin spheroidization, ana zubar da saman ciki na jakar a cikin kwararar inoculant kuma an fasa shi gaba daya, sannan ana nazarin samfurin kuma an gwada shi tare da kayan aikin EPIC. 1.2% wakilin spheroidizing Elkem, 0.8-1.0% wakili mai rufewa, da kuma gilashin gilashi 0.4% an saka su cikin jakar spheroidizing, kuma ana fitar da baƙin ƙarfe kai tsaye cikin jakar spheroidizing, kuma an saka 0.5% Elkem inoculant a lokaci guda. Bayan an gama warkar da warkarwa, za a yi samfurin samfurin Elkem wanda aka yayyafa a farfajiya kuma a bincika ta amfani da kayan aikin EPIC.

1.2% wakilin spheroidizing Elkem, 0.8-1.0% wakili mai rufewa, da kuma gilashin gilashi 0.4% an saka su cikin jakar spheroidizing, kuma ana fitar da baƙin ƙarfe kai tsaye cikin jakar spheroidizing, kuma an saka 0.5% Elkem inoculant a lokaci guda. Bayan an kammala aikin warkar da warkarwa, za a yi samfurin samfurin Elkem da aka yafa a farfajiyar kuma a bincika ta amfani da kayan aikin EPIC.

Kashi na biyu na cajin rabo: 65% baƙin ƙarfe alade, 35% ƙananan manganese. sarrafa abun da ke cikin sinadarai:

| C | Si | Mn | P | S | Cu | |

| Tanderun farko | 3.7-3.9 | 0.6-0.75 | 0.1-0.25 |

Yin amfani da tsarin maganin inhelation na spheroidizing: kai tsaye 500kg na baƙin ƙarfe zuwa tundish, an saka 1.2% Elkem nodulizer, 0.8-1.0% wakili mai rufewa da 0.4% gilashin gilashi a cikin jakar spheroidizing, da baƙin ƙarfe kai tsaye zuwa jakar nodularizing. Sanya 0.5% Elkem inoculant. Bayan an gama aiwatar da aikin warkar da cutar, sanya kwararar Elkem ta hanyar inoculant a saman jakar, fasa shi gaba ɗaya, kuma yi amfani da kayan aikin EPIC don samfuri don bincike da gwaji.

500kg na baƙin ƙarfe za a iya bugawa kai tsaye zuwa tundish, kuma 0.95% Elkem low-magnesium spheroidizing agent, 0.65% Elkem wakilin suttura, 0.2% guntun ƙarfe da 0.1% slag remover an saka su cikin jakar spheroidizing, kuma ana iya buga baƙin ƙarfe kai tsaye zuwa kunshin spheroidizing. Bayan an gama warkar da cutar, an yayyafa allurar binciko na Elkem a farfajiya, an fasa shi gaba ɗaya, kuma ana bincika samfurin kuma an gwada shi da kayan aikin EPIC. Kai tsaye danna 500kg na baƙin ƙarfe zuwa tundish, kuma jakar spheroidizing an haɗa shi da 1.2% Elkem nodulizer, 0.3% wakili mai rufewa, 0.2% Elkem inoculant, 0.5% guntun ƙarfe da 0.1% slag remover, kai tsaye fitar da Iron a cikin jakar spheroidizing, kuma a lokaci guda sanya 0.35% na marasa lafiya na Elkem.

Bayan an gama warkar da cutar, an yayyafa allurar binciko na Elkem a farfajiya, an fasa shi gaba ɗaya, kuma ana bincika samfurin kuma an gwada shi da kayan aikin EPIC. Tsarin na uku shine rabo na cajin: 65% na baƙin ƙarfe alade, 35% na tarkace; sarrafa sinadaran abun da ke ciki:

| C | Si | Mn | P | S | Cu | |

| Tanderun farko | 3.8-4.0 | 1.1-1.4 | 0.1-0.25 |

An karɓi shirin jiyya na spheroidization: 500kg na baƙin ƙarfe ana buga shi kai tsaye zuwa tundish, 1.2% Elkem low-magnesium spheroidizing wakili, 0.8% wakili mai rufewa da 0.1% slag remover an saka su a cikin jakar spheroidizing, kuma ana buga ƙarfe kai tsaye zuwa jakar spheroidizing. A lokaci guda, an sanya 0.55% na Elkem inoculant a ciki. Bayan an kammala aikin warkar da cutar, an sanya Elkem ta hanyar inoculant a saman jakar, wanda ya lalace gaba ɗaya, kuma an bincika samfuran kuma an gwada su da kayan aikin EPIC. Kai tsaye taɓa 500kg na baƙin ƙarfe zuwa tundish, saka 1.2% Elkem low-magnesium spheroidizing wakili, 0.8% Elkem wakilin suttura, da 0.1% slag remover a cikin jakar spheroidizing, kai tsaye buga baƙin ƙarfe zuwa jakar spheroidizing, kuma a lokaci guda saka hannun jari 0.55 % Elkem inoculant. Bayan an kammala aikin warkar da wariyar launin fata, an bijiro da tsarin bincikowa na Elkem wanda aka yayyafa a saman, kuma ana nazarin samfurin kuma an gwada shi da kayan aikin EPIC. Kai tsaye taɓa 500kg na baƙin ƙarfe zuwa tundish, kuma shigar da 1.2% Elkem low-magnesium spheroidizing wakili, 0.3% wakili mai rufewa, 0.2% Elkem inoculant da 0.1% slag remover a cikin jakar spheroidizing, kai tsaye taɓa baƙin ƙarfe zuwa Kunshin spheroidizing, yayin sanya a cikin 0.35% Elkem inoculant. Bayan an gama warkar da cutar, ƙwayar cutar Elkem da aka yayyafa a farfajiyar ta lalace gaba ɗaya, kuma ana bincika samfurin kuma an gwada shi da kayan aikin EPIC. Hanyoyin gano gwaji da hanyoyin bincike An gano carbon da sulfur na narkar da baƙin ƙarfe ta hanyar mai gano sinadarin carbon da sulfur, da kuma abubuwan da aka haɗa kamar P, Mn, da Cu ta mai binciken bakan; Elkem EPIC kayan aikin gano abubuwan sanyaya abubuwa daban -daban na sinadarai a gaban murhu. Misali, LET (zazzabi mai canza yanayin ruwa), CE (ainihin kwatancen carbon), G1, G2, da G3 suna da ƙimar tazara daban -daban. Sakamakon gwaji da tattaunawa Sakamakon da tattaunawa na makirci na farko:

| C | Si | Mn | P | S | Cu | |

| 1-1 | 3.40 | 2.51 | 0.20 | 0.007 | 0.14 | |

| 1-2 | 3.45 | 1.90 | 0.18 | 0.010 | 0.14 | |

| 1-3 | 3.30 | 2.61 | 0.18 | 0.013 | 0.14 |

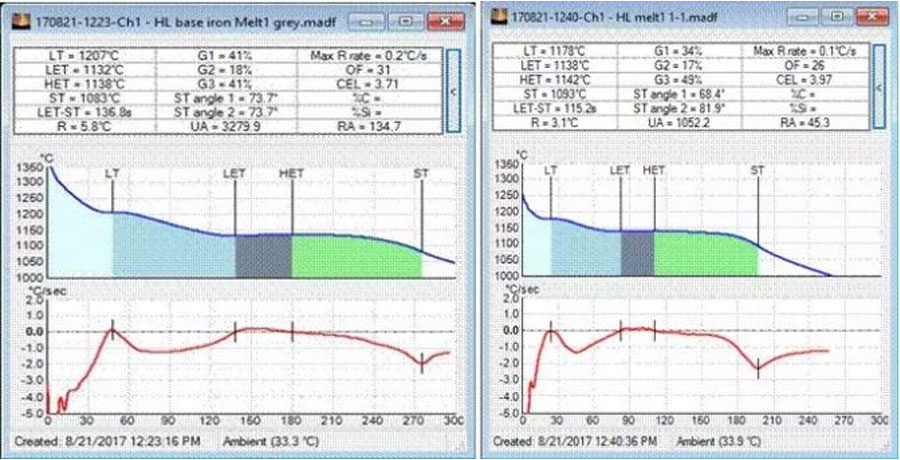

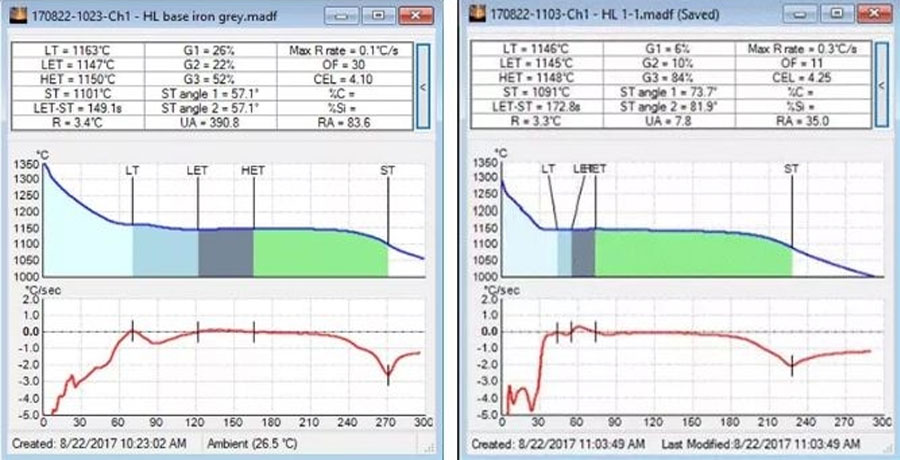

Dangane da hanyoyin sarrafawa daban -daban, hotunan EPIC da aka gano sune kamar haka:

Curve 1: Kangar murhun farko na asali narkakken baƙin ƙarfe ash bakin samfurin

Curve 2: Sakamakon sakamakon shirin murhu na farko A

Curve 3: sakamakon sakamakon tsarin wutar makera ta farko B curve 4: sakamakon sakamakon tsarin murhun wutar farko C

- RomDaga lankwasa 1 da 2, zamu iya ganin ƙimar LET na ƙirar makera na farko A yana ƙaruwa bayan tsarin spheroidization, yana nuna cewa lokacin ruwan sa Zazzabi mai layi yana ƙaruwa, amma tazarar G1 har yanzu tana da girma a 34%, kuma LET -STST lokacin hazo ruwan sama shine dakika 115. Haɗe da sinadaran sinadaransa, an san cewa iskar carbon ɗinsa ita ce mafi girma a tsakanin mafita uku a cikin tanderun farko.

- RomDaga lankwasa 1 da 3, zamu iya ganin ƙimar LET tana ƙaruwa daga 1132 zuwa 1146 ° C, tazarar G1 shine 36%, kuma lokacin hazo na LET-ST graphite shine sakan 129. Haɗe tare da sinadaran sinadaransa, mun san cewa kwatancen carbon ɗinsa shine na farko Mafi ƙasƙanci na zaɓuɓɓuka uku a cikin tanderu ɗaya.

- RomDaga lankwasa 1 da 4, zamu iya ganin cewa lokacin da ƙimar LET ta ƙaru daga 1132 zuwa 1140, tazarar G1 shine 32%. Lokacin hazo na LET-ST graphite shine sakan 139, kuma sinadarin sinadarin carbon ɗin shine ƙimar tsakiyar tsakanin ƙira uku na tanderun farko.

- ④ Mafi girman ƙimar LET, mafi girman ƙarfin ƙarfe ƙarfe mai ƙarfi, ƙananan farin-baki na simintin gyare-gyare a ƙarƙashin yanayi guda ɗaya, da ƙarin ƙwallon ƙira; ƙimar LET-ST shine lokacin hazo mai ruwan hoto. A cikin aiwatar da samar da kauri da manyan sassan, ana buƙatar wannan ƙimar gaba ɗaya. Mafi girma ya fi kyau, yana nufin cewa graphite yana dusashewa yayin aiwatar da ƙarfafawa gabaɗaya, wanda ke da fa'ida don amfani da tasirin faɗaɗa kai na graphite don rama ɓarna ta gefe; tazarar G1 shine tazarar ruwan sama austenite na narkakken ƙarfe. Mafi girman G1, mafi girman halayen ƙarfe ƙanƙantar da porosity. Akwai bangarori biyu da suka shafi ƙimar G1. A gefe guda, shi ne tasirin inoculation da ikon nucleation na narkar da baƙin ƙarfe, kuma a gefe guda, carbon daidai da narkakken baƙin ƙarfe. Lokacin da kwatancen carbon ɗin iri ɗaya ne, mafi kyawun tasirin inoculation, ƙananan ƙimar G1, da ƙaramin yanayin raguwa.

- ⑤ Saboda haka, da alama a cikin tanderun farko bayan maganin baƙin ƙarfe, zaɓi C shine mafi kyau, zaɓi B shine na biyu, kuma zaɓi A shine mafi munin.

Sakamako da tattaunawa na zaɓi na biyu

| C | Si | Mn | P | S | Cu | |

| 2-1 | 3.70 | 2.36 | 0.18 | 0.007 | - | |

| 2-2 | 3.66 | 2.39 | 0.19 | 0.005 | - | |

| 2-3 | 3.46 | 2.65 | 0.18 | 0.005 | - |

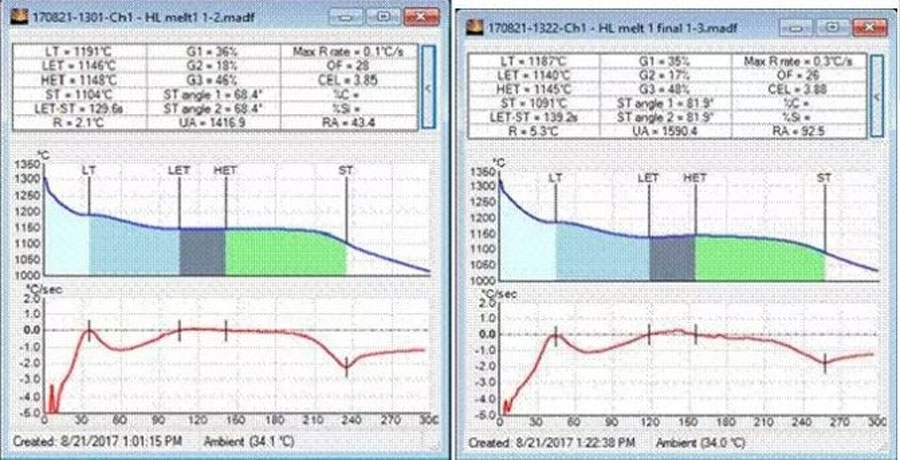

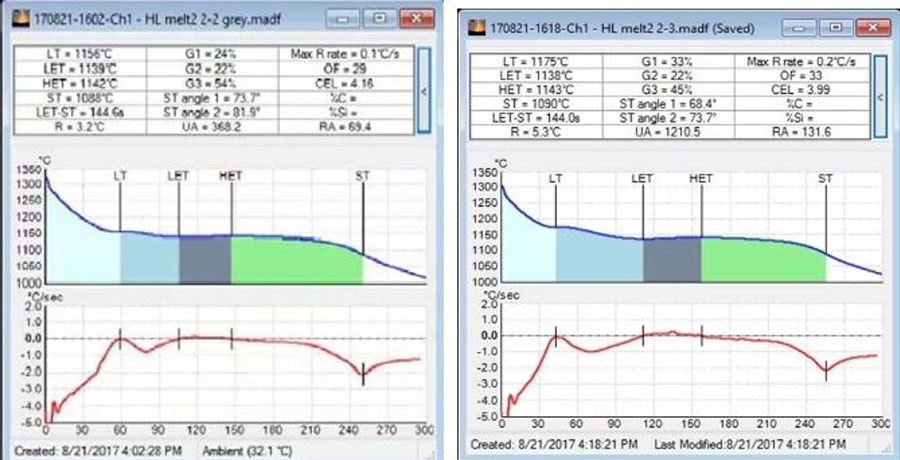

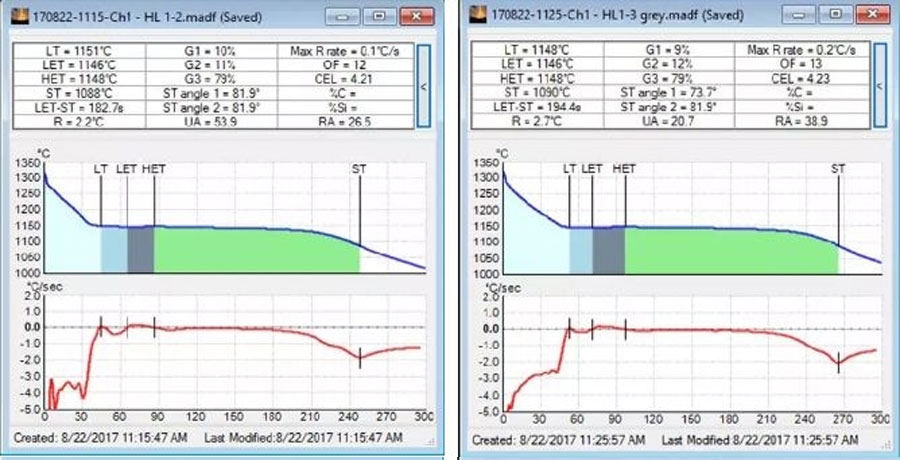

Dangane da hanyoyin sarrafawa daban -daban, hotunan EPIC da aka gano sune kamar haka:

Curve 5: Kangar wutar makera ta biyu ta asali narkakken baƙin ƙarfe ash bakin samfurin

Curve 6: Sakamakon sakamakon shirin murhu na biyu A

Curve 7: Sakamakon sakamakon shirin murhu na biyu B

Curve 8: Sakamakon sakamakon shirin murhu na biyu C

- Ana iya ganin shi daga kwana 5 da lankwasa 6 cewa an rage darajar LET daga 1149 zuwa 1141 ℃, tazarar G1 shine 20%, kuma lokacin hazo na LET-ST graphite shine sakan 146. Haɗe da sinadaran sinadaransa, an san cewa iskar carbon ɗinsa shine tanderu na biyu. Mafi girman shirye -shirye guda uku. Bayan bincike, ƙimar LET na ƙasan murfin baƙin ƙarfe na toka na asali ya kasance saboda ƙari na ferrosilicon da ƙididdige recarburizer, wanda ya haifar da ƙaƙƙarfan ikon nukiliya na narkar da baƙin ƙarfe.

- Ana iya ganin shi daga lankwasa 5 da lankwasa 7 cewa an rage darajar LET daga 1149 zuwa 1139 ℃, tazarar G1 shine 24%, kuma lokacin hazo na LET-ST graphite shine sakan 146. Haɗe da sinadaran sinadaransa, an san cewa iskar carbon ɗinsa shine tanderu na biyu. Tsakanin shirye -shirye guda uku. Dalilin raguwar LET daidai yake da na sama.

- Ana iya ganin shi daga lankwasa 5 da lankwasa 8 cewa an rage darajar LET daga 1149 zuwa 1138 ° C, tazarar G1 shine kashi 33%, kuma lokacin hazo na LET-ST graphite shine sakan 144. Haɗe da sinadaran sinadaransa, an san cewa iskar carbon ɗinsa shine tanderu na biyu. Mafi ƙasƙanci na zaɓuɓɓuka uku.

- General Gabaɗaya, shirin tanderu na biyu A tare da mafi ƙarfin ikon jujjuyawa yana da ƙimar LET mafi girma, ƙaramin haɓakar haɓakar ma shine shirin tanderu na biyu A, kuma ƙimar G1 ita ce mafi ƙanƙanta. Yana nuna cewa ƙimar darajar CE na iya rage ɗimbin ƙanƙancewa da haɓaka ikon haɓakawa.

Sakamako da tattaunawa na zaɓi na uku

| C | Si | Mn | P | S | Cu | |

| 3-1 | 3.72 | 2.36 | 0.24 | 0.008 | - | |

| 3-2 | 3.76 | 2.45 | 0.24 | 0.009 | - | |

| 3-3 | 3.78 | 2.37 | 0.24 | 0.008 | - |

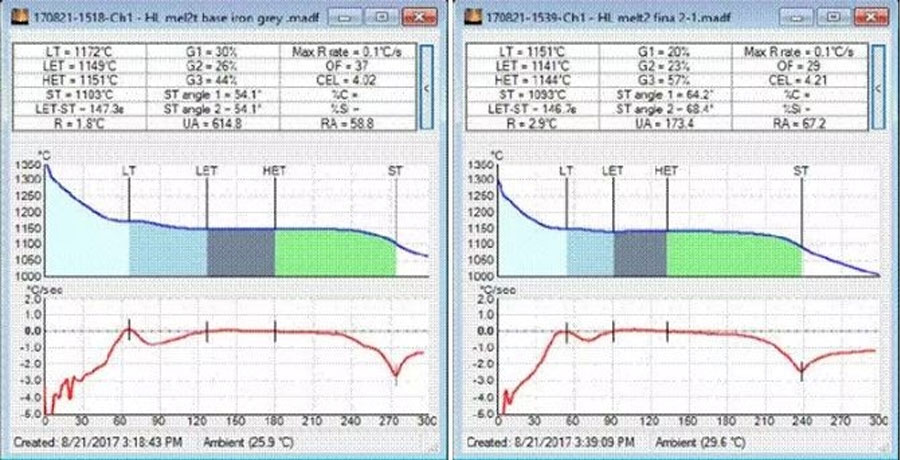

Curve 9: lanƙwasa na tanderu na asali na asali narkakken baƙin ƙarfe ash bakin samfurin

Curve 10: Sakamakon sakamakon shirin murhu na uku A

Mataki na 11: Sakamakon sakamakon shirin tanderu na uku B

Curve 12: Sakamakon sakamakon shirin murhu na uku C

- RomDaga curve 9 da lankwasa 10, ana iya ganin cewa an rage darajar LET daga 1147 zuwa 1145 ℃, ƙimar G1 shine 6%, LET-ST graphite Lokacin hazo shine sakan 172.8, haɗe da sinadaran sinadaran sa, an sani cewa iskar carbon ɗinsa ita ce mafi ƙanƙanta tsakanin ƙira uku na tanderu na uku.

- Ana iya ganin shi daga lankwasa 9 da lanƙwasa 11 cewa ƙimar LET ta ragu daga 1147 zuwa 1146 ° C, ƙimar G1 shine 10%, kuma lokacin hazo na LET-ST graphite shine sakan 182.7. Haɗe da sinadaran sinadaransa, an san cewa iskar carbon ɗinsa shine tanderu na uku. Mafi girman shirye -shirye guda uku.

- Ana iya ganin shi daga kwana 9 zuwa kwana 10 cewa an rage darajar LET daga 1147 zuwa 1146 ℃, ƙimar G1 shine 9%, kuma lokacin hazo na LET-ST graphite shine sakan 194.4. Haɗe da sinadaran sinadaransa, an san cewa iskar carbon ɗinsa shine tanderu na uku. Tsakanin shirye -shirye guda uku.

- Value Gabaɗaya ƙimar G1 na zaɓi na uku yana da ƙarancin ƙarfi, yana nuna cewa narkakken baƙin ƙarfe da wannan zaɓin ke da shi yana da mafi ƙasƙanci na raguwa. Gabaɗaya magana, banbanci tsakanin baƙin ƙarfe ladle na uku ba babba ba ne. Dangane da magana, zaɓin murhun wuta na uku A yana da mafi kyawun sakamako. Ƙarshen gwajin samfurin shine yin amfani da ƙimar carbon daidai gwargwado don daidaita ragin cajin ta hanyar narkakken ƙarfe na tanderun farko da na biyu.

Ƙimar LET na ƙoshin ƙarfe na asali na tanderu na biyu ya fi na tanderun farko, kuma ƙimar G1 ta yi ƙanƙanta da na tanderun farko. Ta hanyar daidaita ragin cajin na tanderun wuta na biyu da na uku, maye gurbin madaidaicin madaurin manganese tare da dunƙule dunƙule, ƙimar LET tana kusa, kuma ƙimar G1 tana raguwa sosai bayan sake dawowa. Sabili da haka, haɓaka abun cikin carbon zai iya inganta ƙarfin nucleation na asalin narkakken ƙarfe da ragewa.

Halin ƙuntatawa yana da ɗan canji tare da nau'in gogewa. Ana samun ingantaccen tsarin warkar da incoulation na spheroidizing ta hanyar gwada tanderun farko A shirin tare da shirin B da shirin C. Wakilin masana'anta na kansa da inoculant suna amfani da hanyar jiyya ta yanzu, kuma ƙuntatawa da haɓaka ƙarfin ikon narkar da baƙin ƙarfe sun fi kyau. Matalauta; Dangane da shirin tanderu na biyu A, shirin B da shirin C, lokacin da sashin maganin spheroidizing shine 1.2% kuma sashin inoculant shine 0.5, tasirin jiyya shine mafi kyau, kuma banbanci tsakanin shigar da shigar da aka taɓa ba babba; ya wuce Kwatanta tsare -tsaren tanderu na uku A, B, da C, babu wani bambanci a bayyane a cikin tasirin tsare -tsaren magani uku.

Dalilin canjin shine ƙimar CE na baƙin ƙarfe na asali. A takaice, tare da babban darajar CE (C3.7-3.9, Si2.1-2.4), ta amfani da Elkem nodulizer inoculant, sashi na nodulizer 1.2%, Elkem inoculant 0.5% da kwararar inoculant na iya samun babban sifa Karfe mai narkar da ikon nukiliya da low shrinkage hali sa ya fi sauƙi a samu ductile baƙin ƙarfe simintin cewa saduwa da ingancin bukatun. Ƙarshen aikace-aikacen don samarwa Yi amfani da ƙarshen gwajin samfurin don samar da ɓangarorin katanga mai kauri. Shirin shine kamar haka: narkar da nauyi 20t, cajin ƙarfe alade 65%, goge karfe 35%, Elkem nodulizer 1.2%, Elkem inoculant 0.5%+tare da Inoculant Flow, asalin ƙarfe C3.7-3.9, Si2.2- 2.5, Mn≤0.3, P≤0.05, S < 0.02, don samarwa, ɗauki sandar gwajin simintin da aka haɗe da simintin don gwaji, da rarrabawa da lura da jikin simintin. Bayan rarrabuwa, an duba yanayin sarrafawa, kuma babu lahani na graphite da ke yawo da raguwa bayan sarrafawa, kuma shirin ya yi nasara.

Don Haɓaka Up

- 1. Ƙarfe-ƙarfe mai kauri mai kauri yana da wuyar sarrafawa a cikin samar da baƙin ƙarfe. Suna da halayen babban kaurin bango, sanyin sannu a hankali, mai ɗauke da Mg da sauran abubuwa, da kuma saurin raguwa. Lahani da ɓarna yayin samarwa yana da sauƙin faruwa, yana haifar da asarar tattalin arziki. Musamman don simintin saiti na QT400-18AR, buƙatun aikin sa: aikin tensile Rm≥390; ƙarfin ƙarfin Re≥240; elongation A≥18; matsakaicin darajar tasirin KV2≥14, ƙimar ƙima KV2≥11, da buƙatu mafi girma.

- 2. Ta hanyar gwajin gwajin ƙaramin samfurin, ana gwada ƙaramin samfurin gwajin yanki don abubuwan haɗin kemikal daban -daban da hanyoyin maganin inhelation na spheroidization daban -daban. EPIC na kayan aikin Elkem yana gano yanayin raguwar baƙin ƙarfe, yana ƙayyade abun da ke cikin sinadaran da ya dace da hanyar maganin nodularization inoculation mai dacewa, kuma yana iya samun narkakken ƙarfe tare da mafi ƙarancin ƙanƙantar da kai.

- 3. Aiwatar da bayanan da aka samo daga ƙaramin gwajin samfurin samfurin zuwa ainihin samarwa don samar da ingantaccen tsari mai tsayayye don samar da sassan katanga mai kauri. Ta hanyar duba sandar gwajin simintin da aka haɗe da lura da yanayin jikin mutum, an ƙaddara cewa shirin yana da tasiri kuma an samar da simintin. Ingancin yana da kyau kuma yana biyan buƙatun inganci.

Da fatan za a adana tushe da adireshin wannan labarin don sake bugawa: Ire -iren Wurare Uku Da Zuba Zuwa Ga Ductile Iron

Minghe Kamfanin 'Yan Wasa Masu Mutu aka sadaukar domin tsirar da samar da inganci da kuma high yi Gyare sassa (karfe mutu simintin sassa Range yafi hada da Thin-Wall Mutu Wasa,Hot Chamber Mutu Wasa,Cold Chamber Mutu Wasa), Zagaye Sabis (Mutuwar 'Yan Wasa,CNC machining,Motsa Motsa, Jiyya na sama) .Adadin al'ada Aluminium ya mutu, magnesium ko Zamak / zinc mutu simintin gyare-gyare da sauran buƙatun simintin maraba don tuntube mu.

Karkashin kulawar ISO9001 da TS 16949, Ana aiwatar da dukkan matakai ta hanyar daruruwan injunan jefa simintin da suka mutu, injunan axis 5, da sauran kayan aiki, tun daga masu fashewa zuwa na’urar Ultra Sonic masu wanki.Minghe ba kawai tana da kayan aiki na zamani ba amma kuma tana da kwararru ƙungiyar ƙwararrun injiniyoyi, masu aiki da sufetoci don tabbatar da ƙirar abokin ciniki ta zama gaskiya.

Manufactureran kwangilar masana'antar mutu. Abubuwan haɓakawa sun haɗa da sassan sanyi na sassan mutuɗar aluminum daga 0.15 lbs. zuwa 6 lbs., saurin canje-canje da aka saita, da aikin inji. Sabis-ƙarin ayyuka sun haɗa da gogewa, faɗakarwa, lalatawa, fashewar harbi, zane, zane, rufi, haɗuwa, da kayan aiki. Abubuwan da aka yi aiki tare sun haɗa da allo irin su 360, 380, 383, da 413.

Zinc ya mutu don jefa ƙirar ƙira / sabis na injiniya tare. Custom manufacturer na daidaici tutiya mutu simintin gyaran kafa. Castananan 'yan simintin gyare-gyare, pressurean ƙwanƙwasa masu juzu'in juzu'in simintin gyare-gyaren juzu'ai, ƙera simintin gyare-gyare na al'ada, ɓangaren mutu da' yan wasa masu mutuwa masu zaman kansu da ƙofar da aka hatimce za a iya ƙera su. Za'a iya kerarrar 'yan simintin a tsayi da faɗi har zuwa 24 a ciki. A cikin +/- 0.0005 a cikin. Haƙuri.

ISO 9001: 2015 bokan masana'anta ta mutu magnesium, Abubuwan haɓaka sun haɗa da matsin lamba na magnesium mai matsi mai yawa har zuwa tan 200 mai ɗumi mai zafi & 3000 ton mai sanyi, ƙirar kayan aiki, gogewa, gyare-gyaren, inji, foda & zanen ruwa, cikakken QA tare da damar CMM , taro, marufi & isarwa.

ITAF16949 bokan. Servicearin Sabis ɗin Gyare Hadawa zuba jari,yashi,Kushin nauyi, Stauren ɓoye ɓoye,Siffar Centrifugal,Cast Vacuum,Dindindin Mould Gyare, .Hanyoyin iyawa sun hada da EDI, taimakon injiniya, ingantaccen samfuri da aiki na sakandare.

Fitar Masana'antu Abubuwan Nazarin sassa don: Motoci, Bikes, Jirgin sama, kayan kiɗa, Jirgin ruwa, Na'urorin hangen nesa, na'urori masu auna sigina, na'urori masu auna sigina, Na'urori, Kayan lantarki, ,unshi, Clocks, Inji, Injiniya, Kayan Kaya, Kayan Jiki, Jigs, Telecom, Haske, Kayan aikin likita, Na'urar daukar hoto, Robobi, Sassaka, kayan sauti, kayan wasanni, Kayan aiki, Kayan wasa da ƙari.

Me Zamu taimake ku yi gaba?

Je zuwa Shafin Farko Don Mutu Wasa China

→Sassan Kasuwanci-Gano abin da muka aikata.

→ Tallan kwankwasiyya Game da Ayyukan Gyare Mutuwa

By Minghe Mutu Wasa Wasa | Categories: Labarai masu Taimakawa |Material Tags: Gyare Aluminum, Zinc Gyare, Fitar Magnesium, Castan Wasanni, Bakin Karfe Cast, Fitar tagulla,Gyare Tagulla,Fitar Bidiyo,Tarihin Kamfanin,Aluminum Mutu Gyare | Comments Off