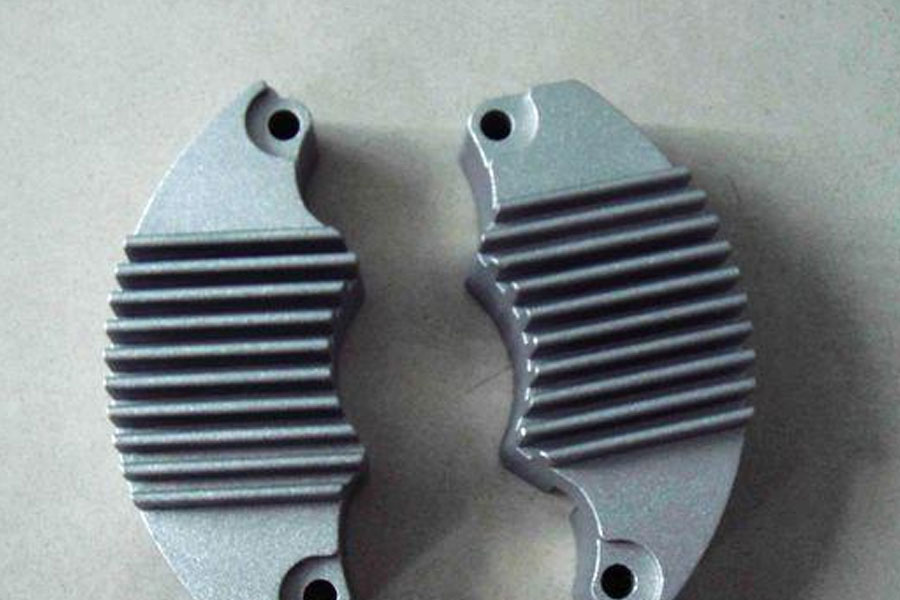

Cikakken Ganowa da Kula da Mota Aluminum Mutuwar 'Yan Wasa

Ana nazarin cikakken bincike da sarrafa ingancin ƙera allurar allurar mutuƙar allurar mota da bincike, kuma ana samun ragi da lahani na gaba. Don sassan aluminum-mutu-simintin sassa, motar silinda tana da babban hanyar haɗi, musamman matsayin murfin kai na shinge na silinda yana ɗaukar babban sarari kuma tsarin ya fi rikitarwa. Wasu sassan hanyoyin da aka sarrafa da farfajiyar silinda dole ne ba su da ramuka da ramuka, waɗanda ke shafar ingancin mutuƙar simintin. Abu na biyu, saboda abubuwan da aka siyo da kayan da aka saya daga waje, ɓarna mai aiki, da sauransu, hakanan yana kawo tasirin inganci ga sassan ƙere-ƙere na motoci. Domin inganta ingancin sassan sassauƙa na motoci, ya zama dole a ƙara darajar hankali ga abubuwan da aka ambata a sama, da haɓaka hanyoyin haɗin tsari da raunin rami.

1 Cikakken ganewar asali da kula da ingancin ƙirar allurar allurar mota ta mutu

1.1 Bayanin lahani na ganewar asali

Don sassan allurar allurar mota ta mutu-simintin baki ɗaya, hanyoyin haɗin motar siliki suna da girman gaske, musamman matsayin murfin kai na jikin silinda yana da babban sarari kuma tsarin yana da rikitarwa. Wasu sassa na hanyoyin da aka sarrafa da farfajiyar silinda ba za a iya haifar da samuwar ramuka da ramuka ba. Ga waɗancan saman silinda waɗanda ke ba da damar ramuka da ramuka su kasance, rarraba ramuka da ramuka sun fi yaduwa, kuma akwai takamaiman bayanai da buƙatun girman. Don haɗin haɗin silinda, matsayin camshaft yana tare da gano aibi. Bayan aiki, girman ramin dole ne ya cika buƙatun saka idanu kuma ya cika mafi ƙarancin ƙa'idodin saka idanu. Don irin wannan nau'in, yana kawo babban wahala ga ƙira da aikin samarwa, kuma yana tasiri sosai kan ƙira da ƙimar samarwa. Fasaha da aiwatar da simintin gyare -gyare ba za su iya yin la’akari da cikakken hanyoyin haɗin gwiwa da matsayi na ɗaukacin simintin ba, kuma yana da ƙarancin jituwa tare da hanyoyin haɗin gwiwa da hanyoyin haɗin tsari. Wasu ganuwar tsutsa suna tare da sifofi masu santsi, kuma zurfin bangon tsutsa yana da girma, tare da matsalolin gurɓataccen iska. Abu na biyu, akwai kuma wasu illoli kamar ramukan da ke haɗa ramukan iska da ramukan ramuka.

1.2 Yi cikakken bincike da bincike da nazarin kwaikwaiyon hoto

Abubuwan da aka saya daga waje da kayan aiki, ɓarna mai aiki, rage ƙirar tsari, da fa'idar amfani da na'urorin inji, da dai sauransu, duk suna da babban tasiri kan amincin simintin mota, wanda ke haifar da canje -canje masu inganci, kuma matsanancin lamura za su haifar da zubar da shara. Abubuwan da aka ambata a sama duk suna da halayen canji, don haka suna da babban tasiri akan ingancin simintin gyare-gyare. Duk wani canji a kowace hanyar haɗi zai kawo canji a cikin ingancin simintin gyare -gyare. Ba abu ne mai sauƙi ba a sami manyan dalilan canje -canje a cikin ingancin simintin gyare -gyare wanda kayan da aka saya da kayan waje suka kawo, ɓarna na aiki, rage ƙirar tsari, da fa'idar amfani da na'u'rorin inji. Idan aka fuskanci wannan yanayin, ya zama dole a haɓaka ci gaba da bin diddigi da bincike kan ƙirar simintin da hanyoyin haɗin gwiwa. Da farko, dole ne mu lura kuma muyi nazarin kwanakin samarwa na simintin gyare -gyare daban -daban, kafa tsarin lokaci mai ma'ana, tabbatar da ingancin simintin a matsayin makasudin jagora, da saka idanu da ci gaba da lura da ragewa mai zuwa. Ciki har da cikakken sa ido da bin diddigin kayan albarkatun ƙasa, kayan taimako, abubuwan narkewa, ƙirar ƙira da aiwatar da sigogin samarwa, saka idanu mai inganci da sauran hanyoyin haɗin gwiwa [21. Don nazarin kwaikwayon hoto, manyan lahani na simintin gyare -gyare suna nunawa a cikin ɗakin kaya. Babban abubuwan da ke haifar da wannan lahani shine tasirin canjin gas da raguwa, wanda ke kawo manyan lahani ga ramuka. Don simintin gyare -gyare, iskar gas ɗin da ake samarwa galibi ana samun ta ne daga cikin narke da gas ɗin da aka samu daga wakilin sakin. Gas da ba a zata ba daga tsarin simintin. Gas da aka samar a cikin maganin yana da alaƙa da kusanci da kaddarorin kayan simintin, kuma yana da alaƙa da fasahar narkar da simintin.

2 Matakan ingantawa da ingantawa

2.1 Gudanar da kwaikwayon hoto da haɓakawa

Don simintin gyare -gyare, iskar gas ɗin da ake samarwa galibi ana samun ta ne daga cikin narke da gas ɗin da aka samu daga wakilin sakin. Gas da ba a zata ba daga tsarin simintin. Iskar da aka samar a cikin maganin yana da alaƙa da kusanci da kaddarorin kayan simintin, kuma yana da alaƙa da fasahar narkar da simintin [41. Iskar gas ɗin da wakilin sakin ke samarwa yana da alaƙa da zaɓin hanyar haɗin tsarin ƙirar simintin gyare -gyare da ƙirar mahaɗin maɓallin simintin. Don wannan rashi a cikin haɓaka simintin gyare -gyare, ana iya amfani da gyare -gyare ga fasahar ƙamshi da daidaita fasahar fesawa don ingantawa da haɓakawa. Akwai dangantaka ta kusa tsakanin raunin iskar gas da simintin gyare -gyare ya kawo a cikin tsarin matsi da nau'in aiki na ƙarfe mai ruwa. Kura -kurai na faɗaɗa da ƙanƙancewar simintin gyare -gyare suna da alaƙa da zafin jiki da ƙarfafawa na simintin. Bayan fayyace tsarin ƙira na simintin gyare -gyare, zaku iya faɗaɗa ƙira da daidaitawar mai gudu, saita layin shaye -shaye da kayan aikin ambaliya, saita zafin jiki na simintin simintin gyare -gyare, da saita maƙallan latsa. Lokacin ƙira da daidaita daidaitattun abubuwa da sigogi na sassan matsawa, ya kamata a yi la'akari da yanayin kwararar ƙarfe na ruwa a cikin simintin gyaran jiki, ya kamata a yi la'akari da ƙarfafawar ruwa, yakamata a rage girman ramin rami, kuma iyaka ya kamata rage girmanta. Bugu da ƙari, ana iya amfani da kwaikwayon hoto don bincike a cikin wannan haɗin. Hanyar kwaikwayon hoto ita ce babbar hanya don nazarin dokar simintin gyare -gyare da fahimtar cika cikarsa a halin yanzu, da kuma samar da tushen kimiyya don dalilan lahani na simintin. Canza samfurin lokacin kuma gabatar da shi a cikin nau'i mai kusurwa uku, sannan ku ba tsarin kwaikwaiyo na fasaharsa da aiwatarwa, da rarrabe tsarin fayil ɗin STL. Bayan ganewa, yi amfani da software na Msgmasoft don fara rarraba cibiyar sadarwa. Ka ba shi nodes cibiyar sadarwa dubu ɗari tare da simintin gyare -gyare da tsarin zubarwa. Bayan zurfin bincike da bincike na software na Msg-masoft, da aikace-aikacen sa na aiki, an gano cewa amfani da software na Msgmasoft yana da fa'ida mai amfani, wanda zai iya gyara da haɓaka sabbin kayan aikin simintin gyare-gyare, da kuma kafa tushe na asali don ƙirar simintin gyare-gyare. molds da matakai. .

2.2 Ƙara sarrafa sarrafa iskar gas

Lokacin da kayan aikin lokacin yana cikin aikin narkewa, cajin da ke cikin ɗakin kayan ya haɗa da 50% na ajiyar aluminium da 39% na tanderun. Saboda danshi da wasu abubuwa za su ci gaba da ƙaruwa yayin aikin sake kunna wutar, wanda zai ƙara yawan iskar gas, sannan ya kamata a bi da kayan kuma a sarrafa su cikin lokaci don rage abubuwan narkar da abun ciki da ƙarawa da cire shi kafin kayan an saka shi cikin tanderun. Don iskar gas da ruwa, an ƙara sa ido da lura da iskar gas. A lokaci guda, yakamata a canza tsari da inganta shi, yakamata a inganta fasahar allura, kuma a daidaita layin allurar don tabbatar da ingantaccen aikin gurɓataccen abu da inganta haɓaka degassing. Tabbatar cewa iskar gas na gram ɗari na kayan aluminium yana kusa da 0.2ml.

2_3 Ƙara mahimmancin ma'aunin tsari da inganta yanayin simintin gyare -gyare

Dangane da sahihancin sigogi na aiwatarwa, da farko, bisa ga sakamakon saka idanu, yakamata a bincika sigogi na tsari da kyakkyawar alaƙar da za ta iya shafar simintin gyare -gyare da yin nazari, kuma za a iya haɓaka ingancin simintin gyare -gyare ba tare da canza yanayin simintin gyare -gyare ba. Domin tabbatar da sahihancin sigogi na aiwatarwa, ana iya amfani da tsarin allura don haɓaka ƙaramin simintin gyare -gyare, matsin gas ɗin cikawa a cikin aiwatarwa, da sauransu, don haɓaka ƙimar tsarin simintin. Abu na biyu, ya zama dole a kara darajar hankali ga yanayin simintin gyare -gyare, tabbatar da aikin da ya dace na aiwatarwa, kara girman hankali ga ramuka, daidaita girman mai gudu, da kuma kara bututu mai fitarwa a cikin mahaɗin ruwa. A cikin ainihin samarwa da ayyukan ƙirar simintin gyare -gyare, ya zama dole a ƙara lura da ramukan jefawa don ganin akwai lahani da rashi, da lura da girman su da shimfida iyaka. Wannan lura da simintin gyare -gyare shine musamman don sa ido kan ainihin amfani da simintin don ganin ko suna buƙatar sokewa da sabunta su. Sassaka hanyoyin haɗin da ba daidai ba na simintin gyare -gyare kuma sake maimaita ɓangarorin da ke da lahani don tabbatar da cewa sun cika buƙatun daidaitattun simintin gyare -gyare da haɓaka aikace -aikacen su. Don kammala simintin gyare -gyare, kula da lura da bangon rami don ganin ko bangon ramin yana da kauri. Ga bangon ramin rougher, galibi yana nuna yanayin rassan bishiyoyi. Lokacin amfani da madubin dubawa don dubawa da bincike, ana iya samun kasan Ci gaba ya fi kyau, tare da raguwa da sassauta tsutsa.

3 jawabin kammalawa

Don sarrafa lahani mai inganci na allurar aluminium na mota, dole ne mu fara haɓaka sarrafa gas ɗin da aka narkar da shi, canzawa da haɓaka tsari, haɓaka ƙimar ma'aunin tsari, haɓaka yanayin simintin, saka idanu da lura da simintin don ganin ko suna buƙatar zama Scrap da sabuntawa. Sake gyara sassan da ke da lahani don tabbatar da cewa sun cika buƙatun daidaitattun simintin gyare -gyare. Don kwaikwayon hoto da nazarin manyan lahani na kaddarorin lokaci na simintin gyare -gyare, zaku iya amfani da daidaita fasahar narkar da simintin gyare -gyare da daidaita fasahar fesawa.

Da fatan za a adana tushe da adireshin wannan labarin don sake bugawa:Cikakken Bincike da Kula da Ingancin Mota na Aluminum Die Castings Quality

Minghe Kamfanin 'Yan Wasa Masu Mutu aka sadaukar domin tsirar da samar da inganci da kuma high yi Gyare sassa (karfe mutu simintin sassa Range yafi hada da Thin-Wall Mutu Wasa,Hot Chamber Mutu Wasa,Cold Chamber Mutu Wasa), Zagaye Sabis (Mutuwar 'Yan Wasa,CNC machining,Motsa Motsa, Jiyya na sama) .Adadin al'ada Aluminium ya mutu, magnesium ko Zamak / zinc mutu simintin gyare-gyare da sauran buƙatun simintin maraba don tuntube mu.

Karkashin kulawar ISO9001 da TS 16949, Ana aiwatar da dukkan matakai ta hanyar daruruwan injunan jefa simintin da suka mutu, injunan axis 5, da sauran kayan aiki, tun daga masu fashewa zuwa na’urar Ultra Sonic masu wanki.Minghe ba kawai tana da kayan aiki na zamani ba amma kuma tana da kwararru ƙungiyar ƙwararrun injiniyoyi, masu aiki da sufetoci don tabbatar da ƙirar abokin ciniki ta zama gaskiya.

Manufactureran kwangilar masana'antar mutu. Abubuwan haɓakawa sun haɗa da sassan sanyi na sassan mutuɗar aluminum daga 0.15 lbs. zuwa 6 lbs., saurin canje-canje da aka saita, da aikin inji. Sabis-ƙarin ayyuka sun haɗa da gogewa, faɗakarwa, lalatawa, fashewar harbi, zane, zane, rufi, haɗuwa, da kayan aiki. Abubuwan da aka yi aiki tare sun haɗa da allo irin su 360, 380, 383, da 413.

Zinc ya mutu don jefa ƙirar ƙira / sabis na injiniya tare. Custom manufacturer na daidaici tutiya mutu simintin gyaran kafa. Castananan 'yan simintin gyare-gyare, pressurean ƙwanƙwasa masu juzu'in juzu'in simintin gyare-gyaren juzu'ai, ƙera simintin gyare-gyare na al'ada, ɓangaren mutu da' yan wasa masu mutuwa masu zaman kansu da ƙofar da aka hatimce za a iya ƙera su. Za'a iya kerarrar 'yan simintin a tsayi da faɗi har zuwa 24 a ciki. A cikin +/- 0.0005 a cikin. Haƙuri.

ISO 9001: 2015 bokan masana'anta ta mutu magnesium, Abubuwan haɓaka sun haɗa da matsin lamba na magnesium mai matsi mai yawa har zuwa tan 200 mai ɗumi mai zafi & 3000 ton mai sanyi, ƙirar kayan aiki, gogewa, gyare-gyaren, inji, foda & zanen ruwa, cikakken QA tare da damar CMM , taro, marufi & isarwa.

ITAF16949 bokan. Servicearin Sabis ɗin Gyare Hadawa zuba jari,yashi,Kushin nauyi, Stauren ɓoye ɓoye,Siffar Centrifugal,Cast Vacuum,Dindindin Mould Gyare, .Hanyoyin iyawa sun hada da EDI, taimakon injiniya, ingantaccen samfuri da aiki na sakandare.

Fitar Masana'antu Abubuwan Nazarin sassa don: Motoci, Bikes, Jirgin sama, kayan kiɗa, Jirgin ruwa, Na'urorin hangen nesa, na'urori masu auna sigina, na'urori masu auna sigina, Na'urori, Kayan lantarki, ,unshi, Clocks, Inji, Injiniya, Kayan Kaya, Kayan Jiki, Jigs, Telecom, Haske, Kayan aikin likita, Na'urar daukar hoto, Robobi, Sassaka, kayan sauti, kayan wasanni, Kayan aiki, Kayan wasa da ƙari.

Me Zamu taimake ku yi gaba?

Je zuwa Shafin Farko Don Mutu Wasa China

→Sassan Kasuwanci-Gano abin da muka aikata.

→ Tallan kwankwasiyya Game da Ayyukan Gyare Mutuwa

By Minghe Mutu Wasa Wasa | Categories: Labarai masu Taimakawa |Material Tags: Gyare Aluminum, Zinc Gyare, Fitar Magnesium, Castan Wasanni, Bakin Karfe Cast, Fitar tagulla,Gyare Tagulla,Fitar Bidiyo,Tarihin Kamfanin,Aluminum Mutu Gyare | Comments Off