Cikakken Nazarin Aluminium Mutu Fitar Mold Crack gazawar

The crack gazawar na aluminum gami mutu-simintin yanayin ba kawai zai shafi mold samar ingancin da samar yadda ya dace, amma kuma ƙara da samar da kudin. A zahirin gaskiya, dalilan da ke haifar da fasawa da gazawar aluminium na mutu-simintin gyare-gyare iri-iri ne. Misali, ƙarfe na ruwa ya sake yin tasiri akan sa, yanayin samarwa yana da zafi-zafi, kayan samar da kayan kwalliya, da EDM da sauran dalilai. A cikin wannan takarda, an gudanar da bincike na musamman kan gazawar fatattaka na mutuƙar simintin ƙarfe na aluminium. Ana fatan zai iya taka rawa wajen jawo sabbin ra'ayoyi, da kawo ƙima ga ma'aikata masu dacewa.

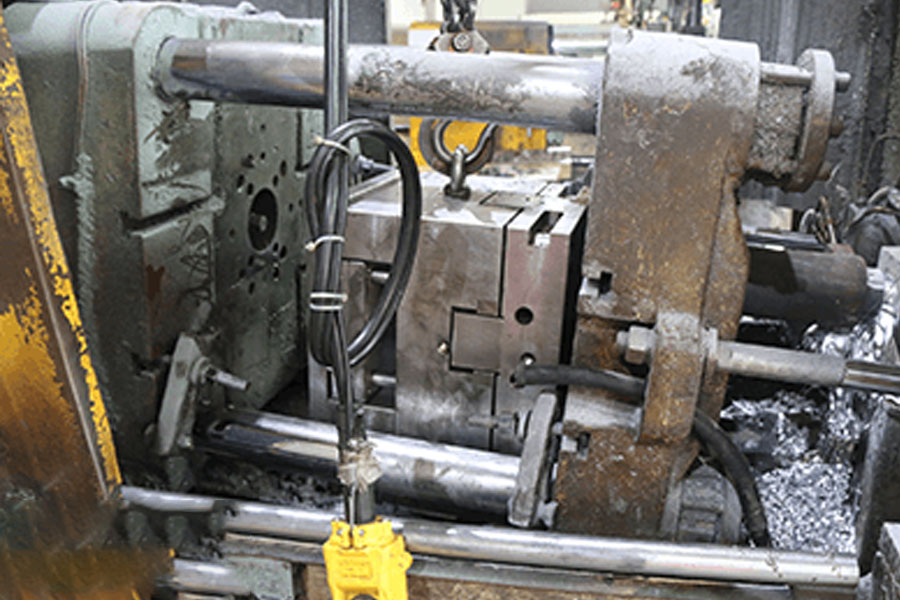

Yanayin aiki na ƙirar aluminium-mutu-simintin gyare-gyare suna dacewa da babban zafin jiki da babban matsin lamba. A lokaci guda, ƙirar aluminium na mutu-simintin gyare-gyare a cikin yanayin aiki yana buƙatar tsayayya da maimaita tasirin ƙarfe mai ruwa. A cikin ainihin samarwa, saboda tsadar farashin aluminium na mutu-simintin kyandirori, sake zagayowar samarwa, da gazawar da ba a daɗe ba, rayuwar sabis za ta ragu sosai. -Da zarar ba a warware matsalar fashewa da gazawar murhun siminti na aluminium ba, zai yi tasiri kai tsaye ga fa'idar tattalin arziƙin masana'antar samarwa. A saboda wannan dalili, ƙarin masana'antun mutu-simintin ƙarfe na ƙarfe na ƙarfe sun haɓaka bincike na gazawar fashewa. Abubuwan da ke biyowa suna ɗaukar aikin ƙarfe na ƙarfe na H13 azaman ƙarfe a matsayin misali, kuma yana haɗa ainihin tsarin samarwa don nazarin dalilan fashewa da gazawar ƙirar ƙirar ƙarfe ta aluminium daga ɓangarorin kayan ƙirar aluminium, microstructure da injin fitar da lantarki. An dauki matakan da suka dace.

1. Dalilin Nazarin Aluminum Alloy Die-Casting Mould Cracking gazawar

Chemical Abun da ke ciki

Daga mahangar abun da ke cikin sinadarai, nau'in baƙin ƙarfe na H13 baƙin ƙarfe ya mutu ƙarfe galibi yana rufe abubuwan da aka tattara na C, SijMn, Mo, Cr, da V. Daga mahangar halayen sunadarai, H13 nau'in ƙarfe irin aikin zafi mutu karfe yana zuwa low Si da high Mo zafi aiki mutu karfe dangane da kayan. A cikin tsarin samarwa, masana'antun za su rage abun cikin Si daidai ko ƙara abun cikin Mo a cikin ƙarfe gwargwadon ainihin buƙatun. Ta hanyar rage abun cikin Si, ana iya rage son zuciya yadda yakamata

Faruwar abin da ke faruwa na hazo, da kuma ƙara tace hatsin austenite, inganta ƙarfi da taurin ƙarfe. Ƙara abun ciki na Mo na iya haɓaka ƙarfin ƙarfi, juriya mai zafi da juriya na ƙarfe. Kuma yadda ya kamata hana hazo na hatsi iyaka carbides a cikin karfe, kazalika da canji na bainite. Aikace -aikacen ya nuna cewa ƙaramin Si da ƙaramin ƙarfe na Mo zai rage yuwuwar yin sanyi a yayin aiwatarwar ƙarfafawa, ta yadda zai hana faruwar dendrites, lu'ulu'u na cellar cellar da rarrabuwa na dendrite. Haɗin abubuwan Mo da V na iya ƙirƙirar carbides na gami, kamar VC, MoC da Mo2C. Alloy carbides zai haifar da yanayi mara kyau wanda aka warwatse a ƙarƙashin yanayin zafin zafin da ya dace, wanda zai inganta ƙimar thermosetting na kayan zafi mai zafi. Kodayake dangane da abun da ke cikin sinadarai, nau'in aikin ƙarfe na H13 ƙarfe yana mutuƙar ƙarfe yana da juriya mai ƙarfi, a cikin ainihin aiki, mun gano cewa aikin ƙarfe na H13 na ƙarfe yana mutuƙar baƙin ƙarfe yana da gazawar farko. Domin ƙarin nazarin abubuwan da ke haifar da gazawar fasa, ya zama dole a haɗa microstructure na H13 karfe mai zafi aikin mutu karfe don ƙarin bincike.

Kayan lantarki

Domin cikakken nazarin microstructure na aluminum gami mutu-simintin kyawon tsayuwa, wannan ɓangaren yana amfani da kayan kwalliyar da ba a yi amfani da su ba bayan ɓarna da ɓacin rai da amfani da kayan ƙirar azaman abubuwan bincike don nazarin microstructure na aluminium gami-mutu-simintin. molds, sannan ku gano Sanadin fasa gazawa.

Abubuwan Mould waɗanda Ba a Yi Amfani da su ba Bayan Kwantar da Wuta da Zazzabi

Ta hanyar aikace -aikace, an gano cewa akwai kyallen kyallen takarda da aka rarraba akan substrate na abin bincike bayan jiyya mai zafi. Ta hanyar lura da abin bincike a ƙarƙashin ƙaramin microscope mai ƙarfi, mun gano cewa an rarraba adadi mai yawa na carbides da aka ɗora akan matrix kuma an ware su. A takaice, idan aka kwatanta da carbides na kyallen takarda na al'ada, wannan ɓangaren carbides Ya fi girma. Saboda hazo mai yawa na carbides da carbides gami, kayan ƙirar suna asarar adadi mai yawa na carbon da ke haɗawa. A karkashin yanayi na yau da kullun, carbides na keɓaɓɓen ƙirar ba zai narke da sauƙi ba lokacin da aka ƙona murfin ta hanyar kashe shi. Koyaya, saboda ƙarancin carbon da abubuwan haɗawa, yana da sauƙin canzawa zuwa martensite a ƙarƙashin zafin zafin zafin jiki, ta hakan yana rage Tempering tauraro mai inganci, kuma yana rage ƙarfi da taurin ƙarfe, yana mai sauƙaƙe karaya yanzu. Ta amfani da ƙaramin madubin microscope don lura da baƙin ƙarfe kafin a kashe injin, mun gano cewa matrix ɗin ƙarfe shima yana da rarrabuwa. Bayyanar wannan sabon abu yana nufin rashin daidaiton kayan albarkatun ƙarfe. Kuma da zarar ba a magance matsalar rarrabuwa yadda yakamata ba, zai ƙara haɗarin fashewar ƙirar da gazawa, kuma zai shafi rayuwar sabis na ƙarshe na ƙirar.

Mould Material Bayan Amfani

A cikin ainihin samarwa, jana'izar aikin ƙarfe na ƙarfe na H13 mai ƙyalƙyali na ƙarfe zai bayyana zuwa digiri daban -daban na fashewa a saman ƙirar bayan kusan sau 30,000 na amfani, kamar: karayar da ke tsakanin juna da tsinkayar ɓarna da yawa Bayan peeling, rami da makamantansu. an kafa. Dalilin wannan sabon abu shine galibi saboda lahani na ƙarfe a cikin albarkatun ƙasa.

EDM

EDM yana ɗaya daga cikin hanyoyin sarrafawa da aka saba amfani da su a cikin ƙirar aluminium na mutu-simintin. Idan aka kwatanta da sauran hanyoyin sarrafawa, wannan hanyar sarrafawa tana gabatar da fa'idodin daidaitaccen aiki mai inganci, babban matakin sarrafa kansa da sauƙin sarrafa sassan da ba su dace ba a cikin takamaiman tsarin aikace-aikacen. Duk da haka, tartsatsin wuta da aka saki yayin sarrafawa suna da halayen babban zafin jiki da matsin lamba, kuma zafin zafin aikin zai kasance

Raguwar kaifi ya sa aka raba saman karfe zuwa yankin sake farfado da yanayin zafi da yankin da zafin ya shafa. Yankin da ake kira thermoremelting zone yana nufin cewa ƙarfe na ƙarfe yana narkewa saboda tsananin zafin da ake fitarwa yayin fitarwa. Domin ba a fitar da narkewar gaba ɗaya ba, kuma narkewar da aka riƙe tana ƙaruwa yayin da ruwan aikin ke sanyaya. An rarraba mafi yawan wuraren da ake jujjuyawar zafi a saman saman saman karfe. Idan aka kwatanta da zazzaɓin da zafi ya shafa a yankin sake juyawa na zafi, abin ƙarfe yana shafar

Bayan an ƙone su da zafi mai zafi, babu wani abin narkewa da ya faru, amma tsarin ƙirar ƙarfe na kayan ya canza daidai. Ta hanyar aiki da yawa, mun gano cewa tsarin ƙirar zafi zai kuma ƙara haɗarin fashewar mold da gazawa a cikin yankin sake farfado da zafi da yankin da zafin ya shafa. Bayan allurar aluminium ta mutu-simintin bayan EDM ta wuce cikin tanderun gas, kodayake tsarin ƙirar ƙirar ƙirar ba ta canza daidai, an sake gyara ta da zafi.

Duk da haka, ƙananan fasa za su bayyana a yankin, kuma lokacin da fasa ya faɗaɗa zuwa yankin da zafin ya shafa, ƙaramin ƙwanƙwasa zai sake ƙaruwa, wanda kuma yana ƙara ƙimar lalacewar fasa ƙura.

2.Ka'idodin Rigakafin Karɓar Rashin Fitar da Allurar Mutuwar Fitar Aluminum

- 2.1 Ƙara yawan samfura don gwajin ƙirar ƙarfe na albarkatun ƙasa don aluminium na mutu-simintin gyare-gyare A cikin ainihin tsarin samarwa, masana'antun da yawa ba su yi cikakken gwajin ƙirar ƙarfe na kayan da aka saya don hanzarta jadawalin samarwa ba. Domin rage aukuwar fasa da kasawa na aluminium na mutu-simintin gyare-gyare, masana'antun suna buƙatar haɓaka adadin binciken ƙirar ƙarfe na samfuran albarkatun ƙasa a cikin annealed da injin da aka kashe da yanayin yanayi, don tabbatar da cewa kayan ƙera sun hadu ainihin abin da ake buƙata yana buƙata zuwa mafi girma. Lokacin cire samfuran kayan kwalliya, mai samarwa yana buƙatar zaɓar wurin ɗaukar samfurin a kimiyance kuma cikin ma'ana. A cikin samfuran samfuran allurar mutuƙar simintin ƙarfe na aluminium, don tabbatar da amincin madaidaicin sashi na asali da gano madaidaicin ingancin ƙirar kayan ƙera, masu kera gabaɗaya suna amfani da ƙofar azaman wurin samfur.

- 2.2 Yadda yakamata ya magance yankin sake kunna wutar zafi wanda EDM ya haifar: Yankin sake jujjuyawar wutar lantarki wanda ke haifar da injin fitar da wutar lantarki yana da tauri mai girma da ƙanƙantar da kai, kuma microcracks suna da saurin bayyana yayin aikin injin. Musamman a cikin tsarin ƙona wuta, yuwuwar ƙananan fasa-ƙwal ya fi girma. Domin gujewa fasawa da gazawar allurar aluminium na mutu-simintin gyare-gyare, ya zama dole a kimiyance kuma a hankali ku guji bayyanar yankin sake buɗe wuta. Bayan EDM, ana buƙatar cire yankin sake kunna zafi cikin lokaci, kuma yakamata a daidaita yanayin a cikin lokaci don kawar da matsi mai yawa na murfin da abin ya shafa. .

- 2.3 Da kyau a guji abin da ya faru na gazawar fashewar farko: Rashin fashewar ƙirar ƙirar mutuƙar simintin ƙarfe na aluminium yana faruwa a farkon matakin, wanda galibi yana haifar da matsanancin zafin zafin ƙirƙira na ɓoyayyiyar faifai. Rashin gazawar da ke haifar da wannan dalili shine lahani wanda ba a iya gyarawa. Sabili da haka, yayin aiwatar da aikin da babu komai, mai samarwa yana buƙatar tsananin sarrafa zafin jabu. A cikin matakin kashe wutar, kuma ya zama dole a shirya lokacin dumama a kimiyance kuma mai ma'ana don sarrafa zafin dumama da hana faruwar lalata. A cikin matakin kashewa da sanyaya jiki, ya zama dole a sarrafa lokacin sanyaya yadda yakamata, kuma a yi ƙoƙarin kammala aikin kashewa da sanyaya cikin mafi kankanin lokaci kuma cikin saurin sauri. Don tashar ruwa mai sanyaya, mai ƙira yana buƙatar kiyaye tazara tsakanin sa da bayanin martaba da kusurwoyin manyan isa don tabbatar da ci gaban aikin sanyin.

- 2.4 Maganin zafi da kimiya mai ƙyalƙyali na ƙyallen: Ingancin albarkatun ƙasa don kyawon tsayuwa yana shafar rayuwar sabis na allurar mutuƙar simintin ƙarfe. Sabili da haka, ma'aikatan suna buƙatar zaɓar madaidaiciyar ƙirar ƙirar mutuƙar siminti dangane da ainihin buƙatun. Bayan mai aikin ya ƙayyade albarkatun ƙasa don ƙirar mutuƙar simintin ƙarfe na aluminium, ya zama dole a gudanar da maganin zafi cikin lokaci. A lokaci guda, ya zama dole a yi aiki mai kyau a cikin tsarin rage damuwa a cikin matakin samarwa don hana ɗaukar hankali, da sarrafa kusurwar R. -Ga gabaɗaya, lokacin da aka yi amfani da murfin murƙushewar aluminium kusan sau 10,000, yana buƙatar yin ɗumi cikin lokaci don cire damuwa, ta yadda za a iya hana ɗaukar danniya daga haifar da ƙirar ta fashe. Don haɓaka lokacin amfani da ƙirar gabaɗaya, ana iya amfani da yawan zafin jiki da hanyoyin taimako na danniya.

- 2.5 A kimiyyance kuma cikin hikima yana sarrafa zafin jiki a cikin tsarin samar da allurar mutuƙar siminti na aluminium: Tsarin samarwa na ƙirar ƙirar ƙarfe na aluminium yana ba da babban zafin jiki da matsin lamba. Sabili da haka, yana da mahimmanci musamman a kimiyance da ma'ana sarrafa zafin jiki a cikin tsarin samarwa. A cikin tsarin samarwa, mai samarwa na iya amfani da ma'aunin ma'aunin zafi da ya dace don ƙididdige matsakaicin zafin jiki a cikin tsarin mutuƙar mutuwa da ɗaukar matakan sarrafawa masu inganci don sarrafa zafin jiki a tsakanin digiri 650.

3. Kammalawa

A takaice, tare da saurin haɓaka tattalin arziƙin ƙasata, masana'antun masana'antar kera mutuƙar siminti na aluminium sun faɗaɗa cikin sauri dangane da lamba da sikelin samarwa. Koyaya, saboda babban saka hannun jari a cikin farashin ƙimar ƙirar aluminium na mutu-simintin gyare-gyare, da zarar ba za a iya ba da tabbacin ingancin samarwa ba, kai tsaye zai shafi ingancin samarwa da gasawar masana'anta. A cikin tsarin samarwa, gazawar fashewar matsala ce ta yau da kullun na ƙirar aluminium-mutu-simintin. Wannan ba kawai ya jawo hankalin mutane da yawa daga masana'antun ba, har ma an yi amfani da shi sosai don shafar masu amfani. A saboda wannan dalili, yana da mahimmanci musamman don haɓaka bincike kan gazawar fasa bututun ƙarfe na aluminium. Abubuwan da ke sama suna nazarin abubuwan da ke haifar da gazawar fasa bututun ƙarfe na ƙarfe na aluminium, kuma yana ba da shawarar matakan kariya daga fatattakar gazawar ƙirar ƙarfe na aluminium akan wannan. Ana fatan zai iya kawo ƙima mai mahimmanci ga ma'aikatan da suka dace da haɓaka ɗorewa, hanzari da ingantaccen ci gaban masana'antar kera kayan ƙarfe na ƙasata.

Labarai iri ɗaya: Dalilan Na'urar Kayan Fitar da Fuskar Aluminum Mai Sauƙi

Da fatan za a adana tushe da adireshin wannan labarin don sake bugawa:Cikakken Nazarin Aluminium Mutu Fitar Mold Crack gazawar

Minghe Kamfanin 'Yan Wasa Masu Mutu aka sadaukar domin tsirar da samar da inganci da kuma high yi Gyare sassa (karfe mutu simintin sassa Range yafi hada da Thin-Wall Mutu Wasa,Hot Chamber Mutu Wasa,Cold Chamber Mutu Wasa), Zagaye Sabis (Mutuwar 'Yan Wasa,CNC machining,Motsa Motsa, Jiyya na sama) .Adadin al'ada Aluminium ya mutu, magnesium ko Zamak / zinc mutu simintin gyare-gyare da sauran buƙatun simintin maraba don tuntube mu.

Karkashin kulawar ISO9001 da TS 16949, Ana aiwatar da dukkan matakai ta hanyar daruruwan injunan jefa simintin da suka mutu, injunan axis 5, da sauran kayan aiki, tun daga masu fashewa zuwa na’urar Ultra Sonic masu wanki.Minghe ba kawai tana da kayan aiki na zamani ba amma kuma tana da kwararru ƙungiyar ƙwararrun injiniyoyi, masu aiki da sufetoci don tabbatar da ƙirar abokin ciniki ta zama gaskiya.

Manufactureran kwangilar masana'antar mutu. Abubuwan haɓakawa sun haɗa da sassan sanyi na sassan mutuɗar aluminum daga 0.15 lbs. zuwa 6 lbs., saurin canje-canje da aka saita, da aikin inji. Sabis-ƙarin ayyuka sun haɗa da gogewa, faɗakarwa, lalatawa, fashewar harbi, zane, zane, rufi, haɗuwa, da kayan aiki. Abubuwan da aka yi aiki tare sun haɗa da allo irin su 360, 380, 383, da 413.

Zinc ya mutu don jefa ƙirar ƙira / sabis na injiniya tare. Custom manufacturer na daidaici tutiya mutu simintin gyaran kafa. Castananan 'yan simintin gyare-gyare, pressurean ƙwanƙwasa masu juzu'in juzu'in simintin gyare-gyaren juzu'ai, ƙera simintin gyare-gyare na al'ada, ɓangaren mutu da' yan wasa masu mutuwa masu zaman kansu da ƙofar da aka hatimce za a iya ƙera su. Za'a iya kerarrar 'yan simintin a tsayi da faɗi har zuwa 24 a ciki. A cikin +/- 0.0005 a cikin. Haƙuri.

ISO 9001: 2015 bokan masana'anta ta mutu magnesium, Abubuwan haɓaka sun haɗa da matsin lamba na magnesium mai matsi mai yawa har zuwa tan 200 mai ɗumi mai zafi & 3000 ton mai sanyi, ƙirar kayan aiki, gogewa, gyare-gyaren, inji, foda & zanen ruwa, cikakken QA tare da damar CMM , taro, marufi & isarwa.

ITAF16949 bokan. Servicearin Sabis ɗin Gyare Hadawa zuba jari,yashi,Kushin nauyi, Stauren ɓoye ɓoye,Siffar Centrifugal,Cast Vacuum,Dindindin Mould Gyare, .Hanyoyin iyawa sun hada da EDI, taimakon injiniya, ingantaccen samfuri da aiki na sakandare.

Fitar Masana'antu Abubuwan Nazarin sassa don: Motoci, Bikes, Jirgin sama, kayan kiɗa, Jirgin ruwa, Na'urorin hangen nesa, na'urori masu auna sigina, na'urori masu auna sigina, Na'urori, Kayan lantarki, ,unshi, Clocks, Inji, Injiniya, Kayan Kaya, Kayan Jiki, Jigs, Telecom, Haske, Kayan aikin likita, Na'urar daukar hoto, Robobi, Sassaka, kayan sauti, kayan wasanni, Kayan aiki, Kayan wasa da ƙari.

Me Zamu taimake ku yi gaba?

Je zuwa Shafin Farko Don Mutu Wasa China

→Sassan Kasuwanci-Gano abin da muka aikata.

→ Tallan kwankwasiyya Game da Ayyukan Gyare Mutuwa

By Minghe Mutu Wasa Wasa | Categories: Labarai masu Taimakawa |Material Tags: Gyare Aluminum, Zinc Gyare, Fitar Magnesium, Castan Wasanni, Bakin Karfe Cast, Fitar tagulla,Gyare Tagulla,Fitar Bidiyo,Tarihin Kamfanin,Aluminum Mutu Gyare | Comments Off