Bincike Akan Tsarin Gatse Molding

Mutuwar simintin yana ɗaya daga cikin mahimman hanyoyi don ƙirƙirar ƙarfe mara ƙarfe. Lokacin aiwatar da mutuƙar simintin, saboda yanayin juzu'i daban-daban na narkakken ƙarfe a cikin rami, abubuwan da ba a so kamar su shingayen sanyi, alamu, pores, da rarrabuwa na iya faruwa. Don hana waɗannan abubuwan da ba a so, yana da mahimmanci don sarrafa kwararar baƙin ƙarfe a cikin rami. Mabuɗin don sarrafa kwararar baƙin ƙarfe a cikin rami ya ta'allaka ne a cikin bincike da ƙira na tsarin ƙurar mutuƙar simintin.

Tsarin Samar da Gurasar Mutuwar Mutuwar

Tsarin CAD/CAE/CAM/CAT na mutu simintin mold yin.

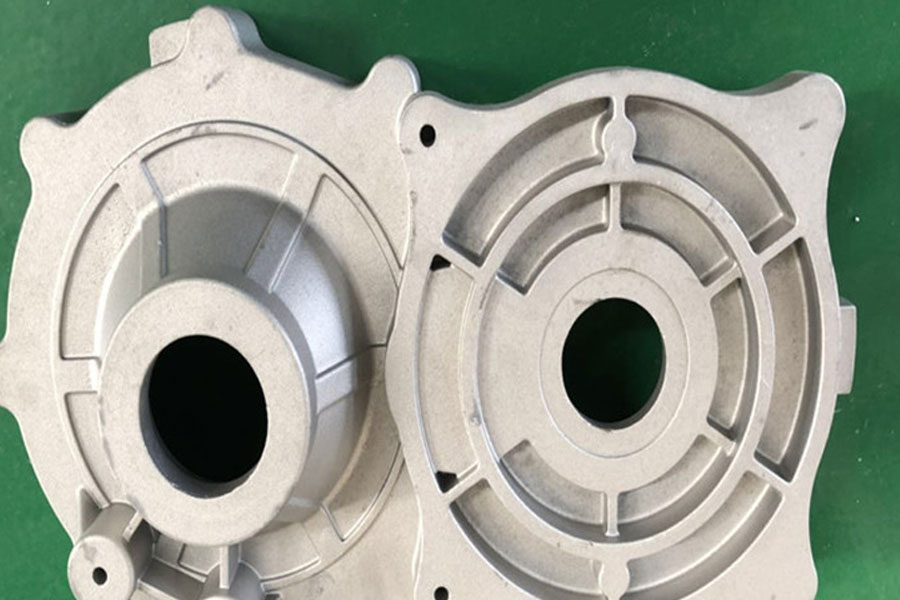

The Design Of The Die Casting Mould Pouring System

A cikin binciken tsarin murƙushewar matattarar mutuƙar, matsayin ƙofar da sifa sune mahimman abubuwan don sarrafa yanayin kwarara da cika alƙawarin mafita. Na farko, mai da hankali kan wurin ƙofar da siffar mai gudu, zana ƙofar, mai gudu, jakar slag, bututun ruwa mai cike da ruwa, da bututun shaye shaye; sannan amfani da software na CAE don nazarin kwararar mafita a cikin rami. Matsayi da girman mai gudu na ciki da ƙofar ciki suna da tasiri mai mahimmanci akan hanyar cikawa.

Siffar Ƙofar Ciki

Lokacin saita ƙofar akan samfurin da aka gama, galibi ana aiwatar da shi gwargwadon tsari mai zuwa:

- Ƙididdigar lissafin yanki mai ƙetare ƙofar: A = U/(vt): ƙarar samfur (cIn.) : A: Yankin giciye ƙofar (cm2)/v: Ƙarfin maganin ƙofar aluminum (cm/s)/T: Cika lokaci (s)

- Yi lissafin yankin sashe na ƙofar ciki.

- Dangane da yankin giciye na ƙofar ciki, saita siffar ƙofar, sannan saita matsayin ƙofar, kuma da farko zayyana matsayin bututun kwarara da jakar slag.

- Yi shirye-shiryen ƙofar daban-daban (yawanci sanya yankin giciye na mai gudu na ciki ya zama mafi ƙanƙanta na farko, da faɗaɗa shi lokacin da ya cancanta bayan gwajin), da yin bayanan 3D.

- Yi bincike na CAE (wato nazarin kwarara) dangane da bayanan 3D da aka samar.

- Kimanta sakamakon bincike.

- Idan akwai abubuwan da ba su dace ba bayan kimantawa, yakamata a inganta shirin, sannan a gudanar da bincike na CAE har sai an sami mafi gamsasshen tsari.

Tsarin Tsarin Sprue da Tsarin Shaye -shaye

Yakamata a saita ƙofar ciki a wani wuri inda narkakken ƙarfe ke gudana mafi kyau a cikin rami, an cika shaye -shaye, kuma duk kusurwoyin ramin za a iya cika da narkakken ƙarfe. Yi amfani da ƙofar ciki a duk lokacin da zai yiwu. Idan ana buƙatar ƙofofi da yawa na ciki, yakamata a kula don tabbatar da cewa kwararar ƙirar ƙarfe ba ta tsoma baki da juna ko saduwa a cikin rami ba tare da tarwatsewa ba (watau jagoran kwararar ƙarfe don gudana ta hanya ɗaya) don gujewa haɗuwa da narkakken ƙarfe a cikin ramin rami.

Lokacin girman girman mutu-jefawa babba ne, wani lokacin ba zai yiwu a sami yankin da ake buƙata na mai gudu daga mai gudu ɗaya kawai ba, don haka dole ne a yi amfani da masu gudu da yawa. Koyaya, yakamata a lura cewa saitin mai gudu na ciki yakamata ya tabbatar da cewa ƙaƙƙarfan ƙarfe yana jagoranta don gudana ta hanya ɗaya kawai, don gujewa raƙuman ruwa yayin da narkar da ƙarfe a cikin rami ya haɗu.

Rarfin ƙarfe na ƙarfe ya kamata ya juye kaɗan kaɗan a cikin rami don karfen ƙarfe ya isa ga ɓangaren katanga mai kauri na simintin mutuwa.

Yaren da aka narkar da ƙarfe yakamata ya zama ɗan gajere da daidaituwa daidai gwargwado.

Yankin giciye na mai gudu na ciki sannu a hankali yana raguwa zuwa mai gudu na ciki don rage shigar gas, wanda ke da fa'ida don haɓaka ƙimar simintin mutu'a. Yakamata mai jujjuyawar cikin yakamata a canza shi cikin nutsuwa yayin aiwatar da kwarara don gujewa juyawa mai kaifi da tasirin tasiri sosai.

Lokacin da akwai ramuka masu yawa, yakamata a rage yankin giciye na mai gudu a ɓangarori gwargwadon ƙimar kowane rami.

Iskar da ke cikin ramin da iskar gas mai shafawa yakamata a tura ta zuwa tsattsarkan ƙarfe mai narkar da ruwa, sannan ta tsere daga ramin daga tsagi. Musamman, kwararar baƙin ƙarfe bai kamata ya bar gas ɗin a cikin ramin makaho ba kuma ya toshe tsattsarkar tsatsa da wuri.

Ruwa na ƙarfe bai kamata ya haifar da girgizar zafi ba akan ɓarkewar zafi mara kyau. Don simintin gyare -gyare da haƙarƙarin haƙora, ƙarfe ya kamata ya kwarara a cikin hanyar haƙarƙarin gwargwadon iko.

Ya kamata a guji cewa narkakken ƙarfe kai tsaye yana wanke sassa da muryoyin da aka lalace da sauƙi. Lokacin da ba za a iya kawar da shi ba, yakamata a saita yankin keɓewa akan ɓarna don gujewa girgizawar zafi.

Gabaɗaya, faɗin faɗin da kauri mai gudu na ciki, mafi girman haɗarin rashin kwararar ruwan sama. A lokaci guda, yi ƙoƙarin kada ku yi amfani da ƙofofi masu kauri. guji nakasawa yayin yanke ƙofofi.

Shakar Ruwa

Ana amfani da tudun ruwa mai zubar da ruwa don cire narkakken ƙarfe da aka fesa da farko yayin da ake yin simintin gyare -gyare da kuma sanya zafin jiki ya daidaita. An saita tsagi na ruwa mai gudana a matsayin inda ƙirar take da sauƙin ɗaukar gas, kuma ana amfani da ita don iskar gas don inganta yanayin kwararar ƙarfe mai narkar da kuma jagorantar narkakken ƙarfe zuwa duk kusurwoyin rami don samun shimfidar ƙasa mai kyau. . An haɗa tsagi mai tsattsauran ra'ayi zuwa gaban ramin da ya cika da jakar slag, ko kuma an haɗa kai tsaye zuwa rami.

Jimlar yankin giciye na ramin shaye-shaye yakamata yayi daidai da yankin sashi na mai gudu na ciki.

An ƙaddara matsayin tsagi a kan rabe -raben gwargwadon yanayin kwararar baƙin ƙarfe a cikin rami. Tsattsarkan tsattsauran ra'ayi ya fi dacewa ya zama "ba madaidaiciya" amma "mai lankwasa" don hana karfen ƙarfe fesawa da cutar da mutane. Zurfin tsagi a kan rabewa yawanci 0.05mm-0.15mm; zurfin tsagi a cikin rami yawanci 0.3mm ~ 0.5mm; zurfin tsagi mai tsini a gefen ƙirar yawanci 0.1mm ~ 0.15mm; Da nisa daga cikin shaye Ramin ne kullum 5mm ~ 20mm.

Rarfin shaye-shaye tsakanin fil ɗin mai cirewa da sandar turawa yana da matukar mahimmanci ga sharar ramin, galibi ana sarrafa shi a 0.01mm-0.02mm, ko kuma ƙara girma har sai an samar da burrs.

Kafaffen babban sharar gida shima hanya ce mai tasiri. Yawancin lokaci, ana sarrafa rata na 0.05mm-0.08mm a gefen gefen ainihin, ta yadda za a buɗe wuyan madaidaicin wuyan tare da faɗin rami mai kauri da kauri na 1mm-2mm, kuma gas ɗin da ke cikin ramin ya buɗe daga shaye rami tare da wuyansa. Ana fitar da shi daga kasan ramin. Bai kamata a yi biris da kazamin ramin da ke shaye shaye ba. Ya kamata ya kula da babban santsi don gujewa toshewa ta fentin da ke manne da datti yayin amfani, wanda zai shafi shaye shaye.

Tattaunawar Tattaunawar Gudun Gudun Hijira da Matakan

A cikin tsarin ƙirar ƙirar, yakamata a ƙyale kwararar ƙarfe ta gudana ta hanya ɗaya gwargwadon iko. Bayan an yi nazarin kwararar, lokacin da aka sami raƙuman ruwa a cikin rami, yakamata a canza kusurwar gubar ko ƙofar ciki don kawar da yanayin halin yanzu.

Lokacin da karfen ƙarfe ya sadu, bari narkakken ƙarfe ya ci gaba da gudana har zuwa wani ɗan tazara kafin a tsayar da kwararar; sabili da haka, ya kamata a ƙara tulun ruwa da jakar leda a waje da rami a mahada don ba da damar narkar da ƙarfe da mahaɗin iska su shiga cikin bututun da ke kwararowa da jakar jakar; bari ƙarfe na ƙarfe na gaba ya kasance mai tsabta kuma a zafin jiki na ɗaki.

Lokacin saurin saurin sassa daban -daban ya bambanta, yakamata a daidaita kauri ko faɗin ƙofar ciki (a hankali ƙara idan ya cancanta) don cimma burin ainihin cikawar guda ɗaya, amma yakamata a samu ta hanyar faɗaɗa mai gudu na ciki sosai. kamar yadda zai yiwu.

Bayan nazarin kwarara, ana samun ɓangaren da ke raguwa, kuma ana iya ƙara mai gudu na ciki. Don sassan sassauƙa na mutuƙar-bango, dole ne a zaɓi ɗan gajeren lokacin cikawa don simintin mutuƙar; saboda haka, yakamata a rage lokacin cikawa ta hanyar haɓaka sashin giciye na mai gudu na ciki don cimma ingantaccen yanayin farfajiya.

Don simintin gyare-gyare na katanga mai kauri wanda ke buƙatar ƙaramin ƙarfi, ya zama dole don tabbatar da ingantaccen iska. Ya kamata a yi amfani da lokacin cika matsakaici don simintin mutu'a. Don haka, ɓangaren giciye na mai gudu na ciki yakamata a daidaita shi don samun lokacin cika daidai kuma samun ingantacciyar farfajiya da ingancin ciki.

A takaice, yayin aiwatar da ƙirar ƙirar mutuƙar, yakamata a biya hankali don gujewa abubuwan da ba a so. Ko da a zamanin yau lokacin da hanyoyin bincike na CAE ke samuwa, a farkon matakin ƙirar ƙira, an fara yin la’akari da ƙwarewar taƙaitaccen tsari a cikin tsarin gating, haɗe -haɗe na jiki, bincika, inganta, da haɓakawa, wanda dole ne a sami sakamako mai yawa tare da rabin kokarin.

Da fatan za a adana tushe da adireshin wannan labarin don sake bugawa:Bincike Akan Tsarin Gatse Molding

Minghe Kamfanin 'Yan Wasa Masu Mutu aka sadaukar domin tsirar da samar da inganci da kuma high yi Gyare sassa (karfe mutu simintin sassa Range yafi hada da Thin-Wall Mutu Wasa,Hot Chamber Mutu Wasa,Cold Chamber Mutu Wasa), Zagaye Sabis (Mutuwar 'Yan Wasa,CNC machining,Motsa Motsa, Jiyya na sama) .Adadin al'ada Aluminium ya mutu, magnesium ko Zamak / zinc mutu simintin gyare-gyare da sauran buƙatun simintin maraba don tuntube mu.

Karkashin kulawar ISO9001 da TS 16949, Ana aiwatar da dukkan matakai ta hanyar daruruwan injunan jefa simintin da suka mutu, injunan axis 5, da sauran kayan aiki, tun daga masu fashewa zuwa na’urar Ultra Sonic masu wanki.Minghe ba kawai tana da kayan aiki na zamani ba amma kuma tana da kwararru ƙungiyar ƙwararrun injiniyoyi, masu aiki da sufetoci don tabbatar da ƙirar abokin ciniki ta zama gaskiya.

Manufactureran kwangilar masana'antar mutu. Abubuwan haɓakawa sun haɗa da sassan sanyi na sassan mutuɗar aluminum daga 0.15 lbs. zuwa 6 lbs., saurin canje-canje da aka saita, da aikin inji. Sabis-ƙarin ayyuka sun haɗa da gogewa, faɗakarwa, lalatawa, fashewar harbi, zane, zane, rufi, haɗuwa, da kayan aiki. Abubuwan da aka yi aiki tare sun haɗa da allo irin su 360, 380, 383, da 413.

Zinc ya mutu don jefa ƙirar ƙira / sabis na injiniya tare. Custom manufacturer na daidaici tutiya mutu simintin gyaran kafa. Castananan 'yan simintin gyare-gyare, pressurean ƙwanƙwasa masu juzu'in juzu'in simintin gyare-gyaren juzu'ai, ƙera simintin gyare-gyare na al'ada, ɓangaren mutu da' yan wasa masu mutuwa masu zaman kansu da ƙofar da aka hatimce za a iya ƙera su. Za'a iya kerarrar 'yan simintin a tsayi da faɗi har zuwa 24 a ciki. A cikin +/- 0.0005 a cikin. Haƙuri.

ISO 9001: 2015 bokan masana'anta ta mutu magnesium, Abubuwan haɓaka sun haɗa da matsin lamba na magnesium mai matsi mai yawa har zuwa tan 200 mai ɗumi mai zafi & 3000 ton mai sanyi, ƙirar kayan aiki, gogewa, gyare-gyaren, inji, foda & zanen ruwa, cikakken QA tare da damar CMM , taro, marufi & isarwa.

ITAF16949 bokan. Servicearin Sabis ɗin Gyare Hadawa zuba jari,yashi,Kushin nauyi, Stauren ɓoye ɓoye,Siffar Centrifugal,Cast Vacuum,Dindindin Mould Gyare, .Hanyoyin iyawa sun hada da EDI, taimakon injiniya, ingantaccen samfuri da aiki na sakandare.

Fitar Masana'antu Abubuwan Nazarin sassa don: Motoci, Bikes, Jirgin sama, kayan kiɗa, Jirgin ruwa, Na'urorin hangen nesa, na'urori masu auna sigina, na'urori masu auna sigina, Na'urori, Kayan lantarki, ,unshi, Clocks, Inji, Injiniya, Kayan Kaya, Kayan Jiki, Jigs, Telecom, Haske, Kayan aikin likita, Na'urar daukar hoto, Robobi, Sassaka, kayan sauti, kayan wasanni, Kayan aiki, Kayan wasa da ƙari.

Me Zamu taimake ku yi gaba?

Je zuwa Shafin Farko Don Mutu Wasa China

→Sassan Kasuwanci-Gano abin da muka aikata.

→ Tallan kwankwasiyya Game da Ayyukan Gyare Mutuwa

By Minghe Mutu Wasa Wasa | Categories: Labarai masu Taimakawa |Material Tags: Gyare Aluminum, Zinc Gyare, Fitar Magnesium, Castan Wasanni, Bakin Karfe Cast, Fitar tagulla,Gyare Tagulla,Fitar Bidiyo,Tarihin Kamfanin,Aluminum Mutu Gyare | Comments Off