Cikakken Bayani Na Kayan Kayan Alloy Alloy Shell Die Casting Tooling

Wannan labarin ya fara nazarin tsarin da tsarin mutuƙar siminti na harsashi na aluminium, kuma yana amfani da software na UG don kammala ƙirar ƙirar ƙirar aluminium. Tabbatacce ta hanyar yin aiki, ƙirar da aka ƙera ta dace, farfajiyar abin da aka samu siminti ne kuma mai tsabta, kuma ingancin samfurin ya cika buƙatun.

Analysis na tsari da aiwatar da mutu-simintin sassa na aluminum gami raya harsashi

- 1.1 Tsarin simintin gyare -gyare Ana iya gani daga hoto na 1 cewa tsarin murfin harsashi na baya yana da sauƙi, kaurin bangon simintin yana da daidaituwa, akwai ramuka guda biyu na jefa, amma saboda bangon ramin simintin yana da kauri, zafi aibobi suna da sauƙin bayyana, Girman bangon gabaɗaya na sassan mutuƙar simintin yana da daidaituwa. Lokacin zabar kaurin bango, yakamata a yi la’akari da abubuwa iri-iri: tsarin mutuƙar simintin, kaddarorin kayan, da tsarin ƙirar mutuƙar da aka ƙera. Kauri mai kauri mai kauri ko kauri kaɗai zai iya saduwa da dukkan fannoni. buƙata.

- 1.2 Ƙananan kaurin bango na gefen waje na simintin. Kyakkyawan yanayin yin simintin gyare -gyare na buƙatar kaurin bangon gefen waje. Dangantaka tsakanin kaurin bangon gefen s da zurfin h shine s≥ (1/4 ~ 1/3) hmm. Lokacin h <4.5mm, sannan s≥1.5mm.

- 1.3 Mutuwar-simintin kayan kayan mutuƙar simintin kayan ƙarfe na aluminium, sa shine YZAlSi9Cu4, ƙarfin ƙwanƙwasawa shine 240MPa, ƙarfin Brinell shine 85HBS, kuma matsakaicin ƙuntatawa shine 0.6%. Abun da aka zaɓa yana haifar da kaddarorin simintin gyare -gyare kuma ya dace musamman don simintin mutu'a.

- 1.4 Radiyon fillet ɗin radiyo Domin yin ƙarfe ƙarfe ya kwarara cikin sauƙi kuma cikin sauƙin fitar da iskar gas, an tsara tsarin don amfani da fillet ɗin simintin, kuma yin amfani da fillet don maye gurbin kusurwoyi masu kaifi na tsarin shima yana iya gujewa fasa. Radius na kusurwowi masu zagaye na tsarin da aka ƙera ya dogara da kaurin bango na tsarin, kuma kewayon gaba ɗaya shine 0.5 zuwa 1 mm.

- 1.5 Yakamata a zaɓi kusurwar tsarawa ta hanyar yin la’akari da abubuwa da yawa: simintin lissafi (zurfin, kaurin bango, rami ko farfajiyar ƙasa), kauri, sarrafa madaidaicin hatsi, da sauransu Yin la'akari da abubuwan da ke sama, ƙirar gangaren rushewar harsashi. na simintin: α = 30 'akan farfajiyar waje, da β = 1 ° akan farfajiyar ciki.

Die simintin aiwatar siga zane

2.1 Zaɓin injin mutu-mutu Lokacin zaɓar injin mutu-simintin, dole ne a ƙaddara ƙarfin matsawa da farko. Ƙarfin ƙwanƙwasa yana da ayyuka biyu: ana amfani da ɗayan don daidaita matsin lamba na baya don cimma manufar kulle farfajiya; ɗayan shine don hana fashewar ƙarfe ƙarfe don cimma manufar cimma daidaiton girma. Babu wani ƙarfafawa na ƙarfafawa a cikin simintin gyare -gyaren da aka tsara, saboda wannan ƙirar ba ta da babban abin jan gefe (simintin mutuƙar ba shi da ramuka na gefe da ƙananan abubuwa). Saboda haka, makullin F ≥ KF main = 1.25 × 1288.352 = 1610.44kN. Dangane da lissafin da ke sama, ana samun ƙimar ƙarfin matsawa da nauyin simintin. Dangane da waɗannan manyan dalilai guda biyu, an zaɓi injin mutu-simintin, kuma samfurin da aka zaɓa na ƙarshe shine: Injin siminti mai sanyi a kwance (2500kN) ——— nau'in J1125, manyan sigogi:

- Volume Mafi girman ƙarfe mai zub da ƙarfe ——— 3.2Kg,

- ThicknessMadadin kauri ———— 250 ~ 650mm,

- ③ Motsa kujerar farantin farantin bugun ———— 400mm,

- Ƙarfin allura—— —143 ~ 280kN.

2.2 Matsi-simintin matse matsi na mutuƙar yana ɗaya daga cikin manyan sigogi a cikin tsarin mutuƙar simintin. Sabili da haka, yana da matukar mahimmanci a fahimci canjin matsin lamba na ƙarfe mai ruwa a lokacin mutu-jefawa tsari, da kuma sarrafa madaidaiciyar matsin lamba a kowane mataki na aikin mutuƙar simintin:

- ① Sami ƙwararrun simintin gyare -gyare—— — —Karancin ƙungiya mai ƙarfi, bayyananne shaci -fadi;

- CalcuLissafin farko na takamaiman matsin lamba - Yi lissafi gwargwadon ƙarfin allurar da aka zaɓa. The musamman matsa lamba allura kuma yana da alaka da mold rami sarari, bango kauri daga cikin simintin, da narkakken karfe tsari da sauran dalilai. Haɗa takamaiman sigogi na ƙirar da aka ƙera da ƙimar farko, allurar takamaiman matsin lamba na wannan ƙirar ta mutu-mutu a ƙarshe an saita zuwa 90MPa.

2.3 Gudun mutuƙar jefa Zaɓin saurin mutuƙar simintin yana da fannoni biyu masu zuwa: zaɓin saurin allura da zaɓin saurin cikawa. Zaɓin saurin gudu biyu yana da matukar mahimmanci, wanda kai tsaye ke ƙayyade ingancin ciki da waje da ma'anar kwane -kwane. Abubuwan da za a yi la’akari da su yayin zaɓar saurin cikawa:

- Size Girman simintin,

- ComplexKarfin tsarin simintin,

- ③ Nau'in gami da aka zaɓa don simintin gyare -gyare,

- Level matakin matsin lamba.

Zaɓuɓɓuka na musamman:

- CastThe simintin gyare-gyare da suka fi sauƙi don cika --- simintin gyare-gyare tare da kauri mai kauri mai sauƙi ko mafi girman buƙatun ingancin ciki, zaɓi: ƙarancin gudu, babban matsin lamba, babban ƙofa;

- Ana buƙatar fillingQara saurin cikawa-hadaddun katanga mai kauri ko Don simintin gyare-gyare tare da buƙatun ingancin ƙasa mafi girma, zaɓi: babban gudu, babban matsin lamba. Cikakken tunani, gwargwadon takamaiman halaye na wannan ɓangaren-mutu-simintin-tsarin yana da sauƙi, zaɓi matsakaicin gudu, kewayon shine 20 ~ 90m/s.

2.4 Lokacin mutu-kayyade yana ƙayyade lokacin mutuƙar, wanda ya ƙunshi sassa uku na lokacin da ake buƙata: lokacin cikawa, riƙe lokaci da lokacin da ɓangaren mutuƙar ya zauna a cikin ƙirar mutuƙar. Abubuwa da yawa sun haɗu don samar da wannan sakamakon: matsin lamba, saurin, zazzabi, narkakken ƙirar ƙarfe, kazalika da tsarin simintin (galibi kaurin bango da ƙarar) da tsarin sifa (musamman tsarin ƙofar da tsarin magudanar ruwa) da sauran abubuwan. Lokacin cikawa galibi tsakanin 0.01 da 0.2s. An ƙaddara tsayin ta hanyar girman simintin gyare -gyare da sarkakiyar tsarin: simintin gyare -gyare tare da tsari mai sauƙi da babban girma yana buƙatar ɗan lokaci mai tsawo na cikawa; simintin gyare -gyare tare da tsari mai rikitarwa da ƙaramin katanga yana buƙatar ɗan gajeren lokaci. Bayan gwaje -gwaje masu amfani, an saita lokacin cikawa a kusan 0.2s, wanda ya dace da matsakaici da ƙaramin alloy mutu simintin da aka tsara a cikin wannan takarda. Aikin riƙe lokacin matsin lamba shine: bugun allurar yana da isasshen lokacin yin amfani da matsin lamba ga ƙarfe wanda ba a tabbatar da shi ba, ta yadda za a iya aiwatar da tsarin crystallization a ƙarƙashin matsin lamba, wanda ke haɓaka ciyarwa kuma ya sami nasarar samun babban tsari. Abubuwan da ke shafar tsawon lokaci: wurin narkewa na abin da aka zaɓa, kewayon zafin crystallization da kaurin bango na simintin. Casting tare da babban narkewa, babban fanni da kaurin bango yana buƙatar dogon lokaci, 2 ~ 3s; lokacin da lokacin da aka ƙaddara ya yi gajarta, ƙuntatawa zai bayyana, amma ba shi da babban tasiri idan lokacin riƙewa ya tsawanta. 1 ~ 2s shine jimlar lokacin riƙewa gabaɗaya. Matsakaicin kaurin bango na simintin a cikin wannan ƙirar shine 3mm. La'akari da tsarinta da kaddarorin gami, an zaɓi 3s azaman lokacin riƙewa. 2.5 Zazzabi zafin-mutu Babban sigogin aiwatarwa don tabbatar da ingantattun simintin gyare-gyare-zazzabin da ke narkar da ƙarfe da zafin zafin aiki. Akwai abubuwa da yawa da ke shafar sa: tsarin simintin, kaurin bango, cika matsin lamba, saurin gudu, da nau'ikan gami. Ya zama dole a yi la’akari da ƙimar sigogin da ke sama don tabbatar da cewa zafin zafin mutuƙar yana da tsayayye a cikin kewayon da ya dace kuma yana ba da kyakkyawan yanayin cikawa. Idan zazzabi mai zubowa baya cikin kewayon da ya dace, ingancin samfurin zai lalace ko ma bai cancanta ba:

Zazzabi mai ɗimbin yawa - zai haifar da raguwar wuce gona da iri yayin sanyaya, samfurin yana iya kamuwa da fasa, manyan hatsi, da ƙarancin injiniyoyin Aiki, har ma yana haifar da ƙyalli, yana rage rayuwar ƙirar;

Low Rashin ƙarancin zafin zafin jiki-yana haifar da lahani ciki har da shinge mai sanyi, ƙirar farfajiya da rashin isasshen zuba. Domin samun ingantattun simintin gyare-gyare, ban da zubar da zazzabi, matsin lamba, zazzabin zazzabi mai mutuƙar mutuwa, saurin cikawa da gami da aka zaɓa don simintin gyare-gyare shima ya kamata a yi la’akari da su a lokaci guda. Sassan sassa na mutuƙar an yi su da aluminium-silicon gami. Dangane da yanayin ruwa da sifar sa, an zaɓi 620 as azaman zafin zafin-mutu.

Tsarin tsari na mutu simintin mutu simintin baya

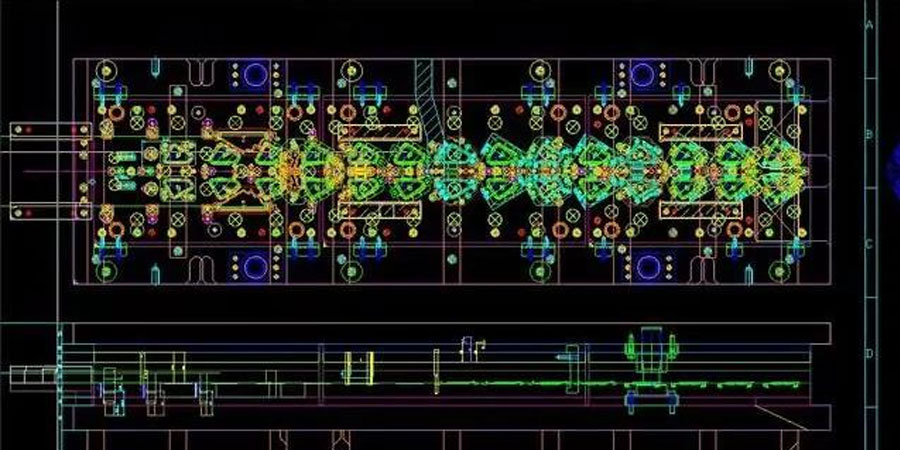

3.1 Tabbatar da Rarraba Bangaren Sashin yana da tsari mai sauƙi. Dangane da ƙa'idar zaɓin farfajiya na ƙasa, yakamata a zaɓi sashin tsinkaya mafi girma, kamar yadda aka nuna a hoto 2.

3.2 Tsararren tsarin ƙofar Tsarin ƙofar ya ƙunshi sassa huɗu:

- Mai gudu kai tsaye

- Mai gudu a kwance

- Gate ƙofar ciki,

- Ramin zamba mai sanyi.

Musamman zane:

- Chamberakin matsa lamba na ciki ---- hanyar haɗi na ɗakin matsa lamba da bushes bushes;

- Siffar giciye na mai gudu —— madaidaicin trapezoid;

- Ƙofar ciki —— ƙofar gefe mai siffar zobe;

- Ide Gefen zuba Bakin da aka shirya akan farfaɗowar simintin;

- Mold Mota ɗaya tare da ramuka huɗu, Hoto 3 yana nuna takamaiman tsari.

3.3 Zane na tankar mai da ambaliyar ruwa Ana aiwatar da ƙirar tsarin tankin da ke kwarara, kuma siffar giciye da aka zaɓa ta hanyar yin la’akari da abubuwa da yawa shine trapezoidal (Hoto 4). Tsarin da ya dace yana da ayyuka masu zuwa:

- MpTarfafa ma'aunin zafin jiki na ƙirar-daidaita yanayin zafi a ko'ina cikin ƙirar, rage alamomin kwarara, shingayen sanyi da rashin isasshen zubin simintin gyare-gyaren, canja wurin ramukan ƙanƙara, ƙanƙantar da porosity, da ɓarna.

- Charge fitarwa Gas ɗin da ke cikin rami yana ƙarewa da sauri tare da tsagi mai ɓarna;

- ③akin ruwan sanyi mai datti na ruwa-cakuda sauran fenti da iskar gas.

3.4 Tsararren tsarin fitarwa A cikin tsarin mutuƙar simintin, bayan an kammala cikakkiyar zagayowar, ana buƙatar buɗe murfin don ɗaukar ɓangaren mutuƙar, kuma za a sami ɓangaren da aka nannade a ƙasan naushi, wanda ke buƙatar cirewa. Wannan aikin yana buƙatar ƙarin nau'in Nau'in babban yanki don aiwatarwa. Tsarin ejector yana da matsayi mai mahimmanci a cikin ƙirar ƙirar ƙirar. Akwai manyan sassa uku na tsarin ejector:

- Ject kore,

- ② sake saiti

- ③ jagora. Wannan ƙirar ƙirar tana ɗaukar hanyoyin fitar da abubuwa guda biyu na ejector, waɗanda ake amfani da su don jefawa da zubar da jini. A diamita na ejector fil ne 6mm da 8mm bi da bi.

Na'urorin iyakance ƙira a cikin tsarin:

- Block iyaka iyaka,

- ② sake saita lever don inganta daidaiton saitin injin kuma hana bugun daga wuce iyaka yayin motsi na kayan aikin.

3.5 Lissafi na girman ɓangaren da aka kafa

3.5.1 Kogo da girman girman:

3.5.2 Yi lissafin tazara na tsakiya da girman matsayi: inda: L-tsakiyar tazarar sashin da aka kafa da matsakaicin girman matsayi (mm); L-matsakaicin girman tsakiyar tsakiyar simintin nesa da matsayin (mm).

3.6 Tsarin tsarin sanyaya yana zaɓar ingantacciyar hanya mai sauƙin sarrafawa mai sauƙin sarrafawa-sanyaya ruwa don samun simintin gyare-gyare masu inganci da tsawon rayuwa. Sakamakon sanyaya ruwa na sanyaya ruwa ya dogara da shimfidar tashar sanyaya, wanda aka shirya a cikin rami:

- ① Mafi yawan zafin jiki,

- HeatZafi ya fi maida hankali,

- Nder Ƙarƙashin tsari,

- SideGaban da ke gaban mai aiki. Don inganta sauƙin shigarwa na bututu na isar da ruwa, ana buƙatar haɗa nauyin ma'aunin geometric na diamita na waje na tashar ruwa. An nuna tsarin sa a cikin hoto 5.

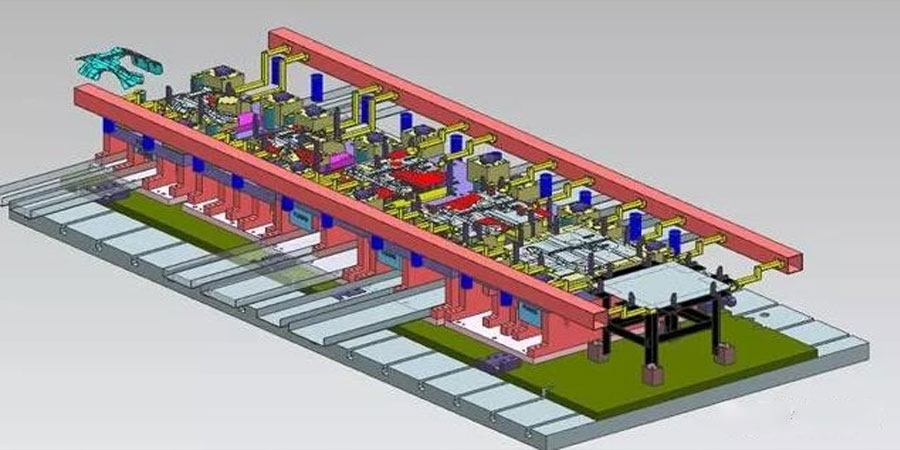

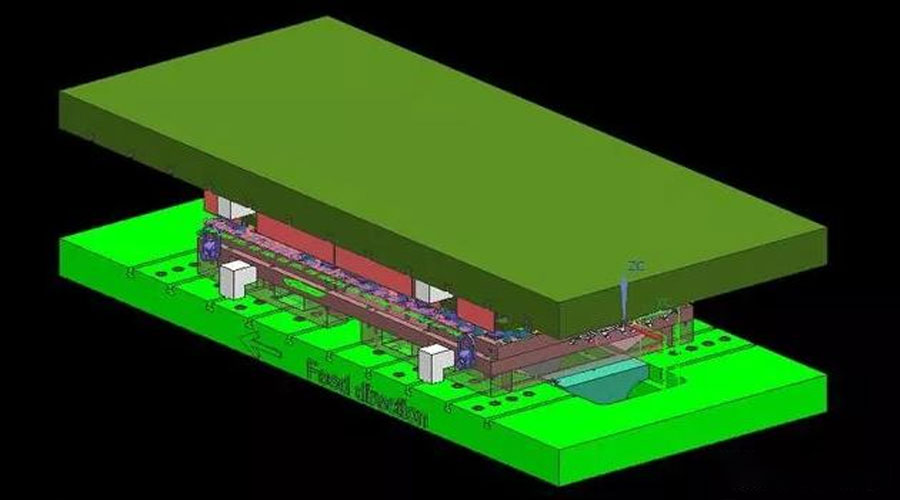

3.7 Babban Zane na Mutuwar Mutuwar Mutuwar Yi babban taron zane na sifar murfin murfin harsashi na baya (Hoto na 6). Mould-simintin mold ya ƙunshi sassa biyu: tsayayyen tsari da motsi mai motsi. Kafaffen ƙirar tana tsaye kuma tana kan farantin ƙirar da aka gyara. Motsi mai motsi yana motsawa tare da farantin mai bi kuma yana kan madogarar madaidaicin farantin. Ana rufe murfin kuma ana buɗe shi ta motsi na motsi mai motsi dangane da motsi mai motsi.

Mould clamping: an rufe su biyun don su zama rami, kuma ramin ya cika da narkakken ƙarfe ƙarƙashin matsin lamba ta amfani da tsarin ƙofar; Opening Buɗewar mold: an raba su biyun bayan an kiyaye matsin lamba, kuma injin fitarwar yana kammala aikin fitar da samfura daga cikin rami.

Wannan labarin yana amfani da software na UG don yin samfuran sassan murfin baya, kuma yana kammala nazarin aiwatarwa, sigogin aiwatar da simintin gyare -gyare da ƙirar tsarin ƙirar sassan murfin baya. Ramin yana iyakance ta abubuwan da ke tafe: ƙira, sarrafawa da Ingancin samarwa, da sauransu, idan aka yi la’akari da abubuwan da ke sama gabaɗaya, an ƙaddara shi azaman madaidaicin madaidaicin huɗu huɗu. Amfani mai amfani yana nuna cewa an zaɓi takamaiman matsi na 90MPa, an zaɓi saurin mutuƙar a cikin kewayon 20-90m/s, lokacin simintin 0.2s, lokacin riƙewa na 3s, da mutuƙar simintin Zazzabi na 620 ℃, sakamakon murfin harsashi na baya Yana da shimfidar wuri mai santsi kuma ya cika buƙatun ingancin samfur.

Da fatan za a adana tushe da adireshin wannan labarin don sake bugawa: Cikakken Bayani Na Kayan Kayan Alloy Alloy Shell Die Casting Tooling

Minghe Kamfanin 'Yan Wasa Masu Mutu aka sadaukar domin tsirar da samar da inganci da kuma high yi Gyare sassa (karfe mutu simintin sassa Range yafi hada da Thin-Wall Mutu Wasa,Hot Chamber Mutu Wasa,Cold Chamber Mutu Wasa), Zagaye Sabis (Mutuwar 'Yan Wasa,CNC machining,Motsa Motsa, Jiyya na sama) .Adadin al'ada Aluminium ya mutu, magnesium ko Zamak / zinc mutu simintin gyare-gyare da sauran buƙatun simintin maraba don tuntube mu.

Karkashin kulawar ISO9001 da TS 16949, Ana aiwatar da dukkan matakai ta hanyar daruruwan injunan jefa simintin da suka mutu, injunan axis 5, da sauran kayan aiki, tun daga masu fashewa zuwa na’urar Ultra Sonic masu wanki.Minghe ba kawai tana da kayan aiki na zamani ba amma kuma tana da kwararru ƙungiyar ƙwararrun injiniyoyi, masu aiki da sufetoci don tabbatar da ƙirar abokin ciniki ta zama gaskiya.

Manufactureran kwangilar masana'antar mutu. Abubuwan haɓakawa sun haɗa da sassan sanyi na sassan mutuɗar aluminum daga 0.15 lbs. zuwa 6 lbs., saurin canje-canje da aka saita, da aikin inji. Sabis-ƙarin ayyuka sun haɗa da gogewa, faɗakarwa, lalatawa, fashewar harbi, zane, zane, rufi, haɗuwa, da kayan aiki. Abubuwan da aka yi aiki tare sun haɗa da allo irin su 360, 380, 383, da 413.

Zinc ya mutu don jefa ƙirar ƙira / sabis na injiniya tare. Custom manufacturer na daidaici tutiya mutu simintin gyaran kafa. Castananan 'yan simintin gyare-gyare, pressurean ƙwanƙwasa masu juzu'in juzu'in simintin gyare-gyaren juzu'ai, ƙera simintin gyare-gyare na al'ada, ɓangaren mutu da' yan wasa masu mutuwa masu zaman kansu da ƙofar da aka hatimce za a iya ƙera su. Za'a iya kerarrar 'yan simintin a tsayi da faɗi har zuwa 24 a ciki. A cikin +/- 0.0005 a cikin. Haƙuri.

ISO 9001: 2015 bokan masana'anta ta mutu magnesium, Abubuwan haɓaka sun haɗa da matsin lamba na magnesium mai matsi mai yawa har zuwa tan 200 mai ɗumi mai zafi & 3000 ton mai sanyi, ƙirar kayan aiki, gogewa, gyare-gyaren, inji, foda & zanen ruwa, cikakken QA tare da damar CMM , taro, marufi & isarwa.

ITAF16949 bokan. Servicearin Sabis ɗin Gyare Hadawa zuba jari,yashi,Kushin nauyi, Stauren ɓoye ɓoye,Siffar Centrifugal,Cast Vacuum,Dindindin Mould Gyare, .Hanyoyin iyawa sun hada da EDI, taimakon injiniya, ingantaccen samfuri da aiki na sakandare.

Fitar Masana'antu Abubuwan Nazarin sassa don: Motoci, Bikes, Jirgin sama, kayan kiɗa, Jirgin ruwa, Na'urorin hangen nesa, na'urori masu auna sigina, na'urori masu auna sigina, Na'urori, Kayan lantarki, ,unshi, Clocks, Inji, Injiniya, Kayan Kaya, Kayan Jiki, Jigs, Telecom, Haske, Kayan aikin likita, Na'urar daukar hoto, Robobi, Sassaka, kayan sauti, kayan wasanni, Kayan aiki, Kayan wasa da ƙari.

Me Zamu taimake ku yi gaba?

Je zuwa Shafin Farko Don Mutu Wasa China

→Sassan Kasuwanci-Gano abin da muka aikata.

→ Tallan kwankwasiyya Game da Ayyukan Gyare Mutuwa

By Minghe Mutu Wasa Wasa | Categories: Labarai masu Taimakawa |Material Tags: Gyare Aluminum, Zinc Gyare, Fitar Magnesium, Castan Wasanni, Bakin Karfe Cast, Fitar tagulla,Gyare Tagulla,Fitar Bidiyo,Tarihin Kamfanin,Aluminum Mutu Gyare | Comments Off