Tasirin Rawar Rawa da Nickel akan Karfin Damage na 4Cr5Mo2V Die Casting Die Karfe

4Cr5 Mo2V galibi ana amfani da ƙarfe-ƙarfe. A cikin tsarin murƙushe aluminium mai mutuƙar mutuwa, saboda yashewa da mannewar narkakken aluminium, ƙirar za ta sami lalacewar zafi, kamar gajiya mai zafi da asarar narkewar zafi, wanda ke haifar da raguwar taurin sa har ma da gazawar da bai kai ba.

Don yin nazarin ko nickel ko bushewa na iya haɓaka juriya na lalacewa na aluminium na mutu-simintin gyare-gyare, 4Cr5 Mo2V karfe da 4Cr5Mo2V tubalan gwajin ƙarfe da ke ɗauke da 1% Ni da 1% Co (ƙungiya mai yawa) an shirya su, kuma an haɗa su bayan quenching da tempering. A cikin madaidaiciyar mutuƙar ƙirar mutuƙar, ƙirar aluminium na ADC12 tare da zazzabi na 800 ℃ daga baya an kashe shi sau 200 zuwa 1,000, kuma an bincika ilimin halittar macro da taurin kan shingen gwajin.

Sakamakon ya nuna cewa bayan mutuƙar simintin ƙarfe na aluminium sau 1,000, toshe gwajin gwajin ƙarfe na 4Cr5Mo2V ya manne da aluminium mafi tsanani kuma ya samar da ƙanƙantattun fasa-kwari; shingen gwajin baƙin ƙarfe na Ni-ɗan ya manne da aluminium, kuma Co-dauke da gwajin gwajin ƙarfe ya manne da aluminium mafi ƙarancin, yana nuna cewa abun cikin 1% Co 4Cr5Mo2V karfe yana da mafi kyawun tsayayyar lalacewar zafi don mutu-siminti aluminium. Bugu da ƙari, idan aka kwatanta da taurin kafin allurar aluminium ta mutu, bayan sau 1,000, mutuƙar siminti, ƙarfin ƙarfe na ƙarfe 4Cr5Mo2V, baƙin ƙarfe na nickel da bushe-dauke da samfuran ƙarfe 4Cr5Mo2V sun ragu da 2.8, 1.8 da 1.4 HRC, wato, da yawa mutu-simintin aluminum gami. Illar da ke tattare da taurin saman ƙarfe da ke ɗauke da busasshen ƙarfe 4Cr5Mo2V ƙasa da na ƙarfe 4Cr5Mo2V, wanda ke da alaƙa da ingantaccen tasirin ƙarfafawa na Co da Ni, wanda ke da fa'ida don haɓaka juriya na lalata ruwa na aluminium na ƙirar kuma sanya ƙirar ta zama mai saukin kamuwa da lalacewar zafi.

Aluminum gami mutu-simintin ne hadaddun high-zazzabi da kuma high-matsa lamba tsari. Akwai abubuwa da yawa waɗanda ke shafar lalacewar zafi (gami da gajiya mai zafi da asarar zafi) aikin ƙirar allurar mutuƙar simintin ƙarfe. Daga cikin su, abun da ke cikin kayan aikin zafi na ƙarfe yana da mahimmanci musamman.

A karkashin yanayi na yau da kullun, ana iya guje wa gazawar mutuwar simintin mutuƙar saboda fasawa da nakasa filastik. Fashewar dusar ƙanƙara galibi ana haifar da taɓarɓarewar injin ko haɗari, wanda ke haifar da matsanancin damuwa. Farkon gajiya mai rauni da fashewar walda (lalacewar yanayin zafi) na kyawon tsayuwar mutuƙar shine manyan hanyoyin gazawa, kuma sau biyu suna shafar juna. 4Cr5Mo2V karfe shine aikin zafi mai mutuƙar mutuƙar amfani, tare da kyakkyawan juriya da juriya na nakasa. Rawa da nickel galibi ana amfani da abubuwan haɗawa, waɗanda zasu iya haɓaka ƙarfi da taurin ƙarfe yadda yakamata, kuma suna da wani tasiri akan tsayayya da lalacewar zafi. Sabili da haka, ana yin nazarin ƙarfe 4Cr5Mo2V, 4Cr5Mo2V wanda ke ɗauke da 1% Ni da 1% Co (ƙaramin taro, iri ɗaya a ƙasa). Ƙarfin ƙarfe don lalacewar lalacewar aluminium yana da babban mahimmanci don jagorantar samarwa na ainihi.

Duk da haka, yawancin hanyoyin yin nazarin lalacewar yanayin zafi na baƙin ƙarfe mai mutuƙar mutuwa kafin baki shine don kwaikwayon dumama da sanyaya jiki. Samfurin baƙin ƙarfe ba ya tuntuɓar narkakken aluminium kai tsaye, kuma baya haɗawa da tasirin murƙushe aluminium, kamar shigar da dumama samfurin baƙin ƙarfe. -A. A cikin wannan takarda, an shirya tubalan gwajin ƙirar ƙarfe guda uku kuma an saka su a cikin ƙirar mutuwa don aiwatar da gwajin mutuƙar ADC12 alloy aluminum. Damage yi na narkakkar aluminum.

1.Test Materials Kuma Hanyoyi

1.1 Kayan Gwaji

Abun sunadarai na ƙarfe 4Cr5Mo2V, ƙarfe 4Cr5Mo2V wanda ke ɗauke da 1% Ni (wanda ake kira 4Cr5Mo2V + Ni karfe) da kuma 4Cr5 Mo2V karfe mai ɗauke da 1% Co (a nan gaba ana kiransa 4Cr5Mo2V + Co karfe) an nuna su a cikin Table 1. An gwada gwajin simintin tare da ADC12 An nuna abun da ke cikin sunadarai na alloy aluminum a cikin Table 2.

| Tebur 1 Abubuwan haɗin kemikal na binciken mutuƙar simintin mutuƙar da aka bincika (gungun taro) % | |||||||

| Material | C | Cr | Mo | V | Co | Ni | Si |

| 4Cr5Mo2V karfe | 0.39 | 4.65 | 2. 21 | 0.46 | - | - | 0. 23 |

| 4Cr5Mo2V+Ni karfe | 0.38 | 4.72 | 2.34 | 0. 51 | - | 1.02 | 0. 21 |

| 4Cr5Mo2V+Co karfe | 0.41 | 4.67 | 2.40 | 0.48 | 1.03 | - | 0. 24 |

| Tebur 2 Haɗin Sinadarai na ADC12 Alloy % | |||||||||

| Sinadarin | Cu | Mg | Mn | Fe | Si | Zn | Ti | Pb | Sn |

| Sakamakon Sakamakon | 1.74 | 0.22 | 0.16 | 0.76 | 10.70 | 0.87 | 0.064 | 0.035 | 0. 010 |

1.2 Hanyar Gwaji

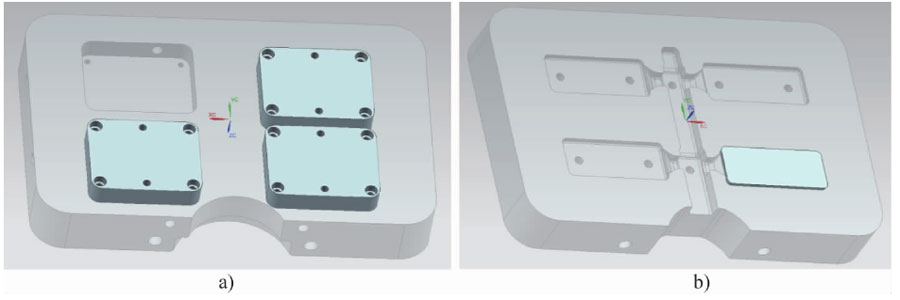

Karfe 4Cr5Mo2V, 4Cr5Mo2V + Ni karfe da 4Cr5Mo2V + Co karfe an sarrafa su zuwa tubalan gwaji kamar yadda aka nuna a Hoto na 1.

An saka lambar rukuni na toshe gwajin a cikin tsagi na madaidaiciyar ƙirar, kuma an saita ramin allurar aluminium da aka mutu a cikin ƙirar mai motsi, kamar yadda aka nuna a Hoto na 2. kuma an yi amfani da ƙirar da aka ƙera don gwajin mutuƙar ADC500 takardar alloy na aluminium, kuma an sake amfani da gami na aluminium. Zazzabi na narkakken aluminium ya fi girma, 12 ° C, don hanzarta gwajin (gabaɗaya, zafin zafin mutuƙar ADC800 alloy aluminum shine (12 650) ° C). Tun da zafin zafin narkakken aluminium shine 120 ℃, wanda baya kaiwa wurin narkewa na mahaɗin Fe-A800, mahallin da zai haifar zai kasance a cikin narkakken aluminium a matsayin ƙazanta bayan faduwa. Amfani da narkakken aluminium shima zai haifar da karuwar ƙazanta da ƙarfafa aluminium. Sakamakon bugun ruwa, ta hakan yana hanzarta gwajin.

Bayan gwajin mutuƙar simintin, an yi amfani da madubin duba na sitiriyo don lura da abin da ke mannewa aluminium a saman shingen gwajin; an yi amfani da na'urar microscope mai zurfi mai zurfi don ƙara lura da matakin mannewar aluminium da ko akwai fasa a saman shingen gwajin.

2.Sakamakon Gwaji Da Nazari

2. 1 Surface Morphology Of The Block Block

2.1.1 Fuskar Allon Aluminum

Hoto na 3 yana nuna ƙirar ƙasa na tubalan gwajin ƙarfe uku ba tare da simintin mutu'a ba kuma bayan sau 600,1000 na simintin mutuwa. Ana iya gani daga Hoto na 3 (b, e, h) cewa bayan sau 600 na mutu-simintin, toshe gwajin gwajin ƙarfe na 4Cr5Mo2V yana da mafi girman aluminium.

Ginin gwajin ƙarfe na 4Cr5Mo2V + Co yana manne da mafi ƙarancin aluminium. Hoto 3 (c, f, i) yana nuna cewa mannewar aluminium a saman tubalan gwajin uku ya ƙaru bayan sau 1,000 na simintin mutuwa. Farfajiyar shingen gwajin ƙarfe na 4Cr5Mo2V yana da mannewar aluminium a bayyane, yayin da sauran tubalan gwajin guda biyu suna da mannewar aluminium kaɗan. Gwajin ƙarfe na 4Cr5Mo2V + Co Ƙunƙarar aluminium ita ce mafi ƙanƙanta da daidaituwa, yana nuna cewa ƙarfe mai ɗauke da lu'u-lu'u 4Cr5Mo2V yana da mafi kyawun juriya ga lalacewar aluminium na ruwa, yayin da ƙarfe 4Cr5Mo2V shine mafi muni. Ƙarin abubuwan rawar jiki da abubuwan nickel suna da fa'ida don daidaita ƙarfin zafin zafin karfe 9-10, kuma farfajiyar ba ta da sauƙi don "taushi" yayin tuntubar juna tare da narkar da aluminium, don haka juriya na yashewar aluminum ya fi kyau, da mannewar aluminium. kadan ne. A lokacin gwajin mutuƙar, aluminium mai narkewa yana shiga cikin rami don tuntuɓar toshe gwajin, kuma tsarin da bai dace ba na shingen gwajin, yankin lahani na injin da sauran yankuna za su manne da aluminium. Aluminium a cikin yankin da ke da alaƙa da aluminium zai amsa tare da ƙarfe don samar da Fe.} Al mai tsaka-tsakin fili, wanda za a karye kuma ya ɓarke a ƙarƙashin raƙuman ruwa mai ƙarfi na aluminium, wanda ke haifar da ramuka a saman farfajiya, da ƙari muhimmin haɗin gwal na aluminium a ƙarƙashin raunin ruwan aluminium.

2.1.2 Fashewar Fuska

Hoto na 4 yana nuna zurfin zurfin ilimin yanayin filin 4Cr5Mo2V karfe, 4Cr5Mo2V + Ni karfe da 4Cr5Mo2V + Co ƙirar ƙarfe bayan sau 1,000 na simintin mutu. Ana iya gani daga siffa 4 (a) cewa akwai ƙaramin adadi na ƙanƙara da aka rarraba a cikin kusan sifar da ke saman farfajiyar gwajin ƙarfe na 4 Cry Mot V. A manne aluminum da narke aluminum amsa tare da karfe don samar Fe.} Al mahadi. Ƙididdigar faɗaɗawar zafi na Fe.} Al ya bambanta da na matrix, wanda ya haifar da ƙaramin adadin microcracks a cikin manne na aluminium da Fe.} Al da mahadi. Sakamakon daɗaɗɗen ƙarfe na aluminium yana sa microcracks su yi taɓarɓarewa, kuma narkakken aluminium ya shiga cikin fashewar kuma ya sake yin ma'amala da matrix don samar da mahaɗan Fe 2 Al. A m maimaita mutu-simintin tsari, da Fe.} Al mahadi a farfajiya na gwajin toshe kashe don samar da ramuka. Bayan tsabtacewa da tsaftacewa na ultrasonic, farfajiyar shingen gwajin ya bayyana kama da halaye masu kama da ruwa mai kama da ruwa. Hoto na 4 (b, c) yana nuna cewa babu fasa a cikin ƙarfe na 4Cr5Mo2V + Co da 4Cr5Mo2V + Ni tubalan gwajin ƙarfe, yana nuna cewa ƙari na 1% rawar soja ko molybdenum ba zai iya rage adhesion na ƙasa kawai ba, amma kuma rage da fatsi hali na mold da inganta aluminum juriya Liquid lalacewa yi. Haɗin abubuwan nickel da lu'u-lu'u waɗanda ba carbide ke haifar da abubuwa na iya haɓaka tsananin zafin zazzabi na ƙyallen, kuma lu'u-lu'u na iya haɓaka watsawa da hazo na molybdenum carbide yayin aiwatar da zafin jiki, da haɓaka tasirin taurin hazo 'z-} 3. Binciken da Ling Qian et al. ya nuna cewa ƙarin abubuwan da ke tabbatar da ƙarfafawa na ƙarfe na ƙarfe mai mutuƙar mutuwa na iya rage yawan damuwa. Dukansu rawar soja da nickel abubuwa ne da ke faɗaɗa yankin austenite, don haka ƙarfe 4Cr5Mo2V + Ni da 4Cr5Mo2V + Co ƙarfe na mutuƙar simintin farfajiya ba sa saurin fashewa.

A narkakkun aluminum a cikin ainihin mutu-simintin tsari ne sosai karfi da mold. Dangane da tsarin lokaci na Fe-A1, mahaɗan Fe-Al intermetallic mahaɗan da aka ƙera ta hanyar ƙarfe da narkakken aluminium galibi FeAlz, Fez A15, FeA13, da sauransu, waɗanda ke da rauni. ka rabu da matrix ɗin ka shigar da narkakken aluminium a ƙarƙashin raƙuman da aka narkar da aluminium, ka bar ramuka a farfajiya. Haɗuwa da sashin ƙarfe na aluminium da ramuka masu ƙyalƙyali yana da ƙarfi kuma baya faɗuwa, kuma yana ƙara samar da abubuwan haɗin Fe A1. Aluminium, Fe.} Al da mahaɗan da ke manne a wurin suna iya kamuwa da microcracks yayin sanyaya. Takardar mutuƙar simintin yana da ƙarancin aluminium mai ruwa, don haka yana ƙarfafawa da sauri, kuma abin da ke tsakanin ƙirar da aluminium ɗin ruwa yana da hankali. Sabili da haka, farfajiyar shingen gwajin yana da ramuka kaɗan saboda halayen Fe da Al, kuma ana samar da ƙarin aluminium mai ɗorewa ta hanyar rushewar ruwa na aluminum.

2. 2 Taurin Surface

Teburin 3 shine matsakaicin darajar farfajiyar farfajiya na shingen gwajin baƙin ƙarfe uku bayan lokuta daban -daban na simintin mutu. Bayanai a cikin Teburin 3 suna nuna cewa taurin saman nau'ikan tubalan gwaji uku suna raguwa kaɗan. Kamar yadda adadin mutu simintin kyawon tsãwa ƙaruwa, shi ne daidai da maimaita tempering na gwajin block, don haka taurin rage. Bayan sau 1,000 na mutu-simintin, taurin 4Cr5Mo2V + Co gwajin gwajin ƙarfe yana da mafi ƙarancin raguwa, wanda shine 1.4 HRC; toshe gwajin gwajin ƙarfe na 4Cr5Mo2V yana da mafi ƙarancin raguwa.

Babu shakka, ya ragu da 2. 8 HRC; taurin saman 4Cr5Mo2V + Ni gwajin gwajin ƙarfe ya ragu da 1. 8 HRC. Stable mold taurin yana da fa'ida don rage ƙyallen aluminium, wato yana da fa'ida don tsayayya da lalacewar zafin-mutu.

| Tebur 3 Taurin taurin tubalan gwajin bayan simintin mutuwa don lokuta daban -daban % | ||||||

| Material | Babu Mutuwar Mutuwa | 200 Times | 400 Times | 600 Times | 800 Times | 1000 Times |

| 4Cr5Mo2V karfe | 48.6 | 48.4 | 48.1 | 47.2 | 46.9 | 45.8 |

| 4Cr5Mo2V+Ni karfe | 47.5 | 47.4 | 47.2 | 46.8 | 46.9 | 46.1 |

| 4Cr5Mo2V+Co karfe | 47.7 | 47.5 | 47.1 | 46.5 | 46.2 | 45.9 |

Bayan lokaci mai tsawo da zafin baƙin ƙarfe, martensite ya ruɓe kuma carbides na sakandare ya zama m, wanda ke haifar da raguwar taurin ƙasa. Dukansu rawar soja da nickel ba carbide kafa abubuwa, wanda zai iya maye gurbin Fe atoms don yin ƙarfe m bayani ƙarfafa '5 zuwa' 8, don haka da cewa mold yana da mafi girma high zafin jiki ƙarfi da kuma kula da mafi taurin bayan maimaita m dumama da sanyaya. Ƙungiyar simintin gyare-gyare ta kasar Sin ta yi nazarin rabe-raben sinadarin a cikin baƙin ƙarfe na Cr-Mo-V-Ni, kuma ta gano cewa yayin aiwatar da zafin jiki, za a wadatar da abubuwan Ni a kusa da carbides, ta hakan yana hana ƙwayoyin carbon a cikin ferrite a kusa. Carbides Ci gaba da yaduwa na carbides yana ƙara ƙarfin kunnawar carbide coarsening, yana hana ci gaban carbides, ta hakan yana rage raguwar taurin ƙarfe mai ɗauke da baƙin ƙarfe 4Cr5Mo2V, da haɓaka juriyarsa ga gurɓataccen lalacewar aluminium.

Ƙungiyar simintin gyare -gyare ta ƙasar Sin ta yi nazarin yanayin kwanciyar hankali da canje -canje na ƙananan ƙarfe na baƙin ƙarfe tare da 1% Ni kuma ba tare da Ni ba, kuma ta gano cewa a ƙarshen matakin gwajin kwanciyar hankali, nickel zai rage taurin baƙin ƙarfe, don haka yin da karfe mafi kyau thermally barga Jima'i. Hakowa abu ne wanda ke faɗaɗa yankin austenite. Ƙara rami zuwa 4Cr5Mo2V ƙarfe na iya haɓaka rushewar carbides yayin aiwatar da aikin austenitization, haɓaka abun cikin carbon na austenite, da haɓaka kwanciyar hankali na austenite, ta haka yana ƙara yawan riƙe austenite Adadin tensite da taurin martensite, kuma rawar zata iya kuma inganta watsawa da hazo na carbide molybdenum yayin aiwatar da zafin jiki, da haɓaka tasirin tauraron hazo z'-1.

Sakamakon ƙarfafawa na nickel da rawar jiki akan matrix yana sa toshe gwajin gwajin mutuƙar ƙarfe har yanzu yana da taurin ƙasa mafi girma bayan maimaita murɗaɗɗen ƙarfe na aluminium, don ya zama mafi tsayayya ga lalata, wanda ke da fa'ida don haɓaka juriya na toshe gwajin ga lalacewar narkakken aluminium. Ƙarfin farfajiyar shingen gwajin da matakin adhesion na aluminium shima yana nunawa (duba Hoto na 3, Tebur 3): Toshin gwajin ƙarfe na 4Cr5 Mo2V yana da mafi ƙarancin ramuka na ƙasa da mannewar aluminium bayan sau 1,000 na mutu-simintin, wato, juriya ga lalacewar ruwa na aluminium shine mafi kyau. Sabili da haka, tasirin ƙarfafawa na ƙara 1% Co zuwa ƙarfe ya fi girma fiye da ƙara 1% Ni, duka biyun suna da kyau don inganta aikin lalata aluminium na mutuƙar ƙarfe.

3.Conciko

- Bayan mutuƙar siminti na aluminium sau 1, samfurin ƙarfe na 000Cr4 Mo5V tare da rami yana ɗaukar mafi ƙarancin aluminium, kuma samfurin ƙarfe na 2Cr4Mo5V ya manne mafi yawan aluminium, wato, ƙarfe 2Cr4 Mo5V tare da rawar soja yana da mafi kyawun juriya na lalacewar zafi.

- Bayan mutuƙar siminti na aluminium sau 1,000, taurin saman 4Cr5Mo2V karfe, 4Cr5Mo2V + Ni karfe da 4Cr5Mo2V + Co ƙirar ƙirar ƙarfe ta ragu da 2.8, 1.8 da 1.4 HRC, wato ƙari na nickel ko rawar jiki na iya inganta juriya na lalacewar Thermal na 4Cr5Mo2V mutu-simintin mutu karfe.

Da fatan za a adana tushe da adireshin wannan labarin don sake bugawa: Tasirin Rawar Rawa da Nickel akan Karfin Damage na 4Cr5Mo2V Die Casting Die Karfe

Minghe Kamfanin 'Yan Wasa Masu Mutu aka sadaukar domin tsirar da samar da inganci da kuma high yi Gyare sassa (karfe mutu simintin sassa Range yafi hada da Thin-Wall Mutu Wasa,Hot Chamber Mutu Wasa,Cold Chamber Mutu Wasa), Zagaye Sabis (Mutuwar 'Yan Wasa,CNC machining,Motsa Motsa, Jiyya na sama) .Adadin al'ada Aluminium ya mutu, magnesium ko Zamak / zinc mutu simintin gyare-gyare da sauran buƙatun simintin maraba don tuntube mu.

Karkashin kulawar ISO9001 da TS 16949, Ana aiwatar da dukkan matakai ta hanyar daruruwan injunan jefa simintin da suka mutu, injunan axis 5, da sauran kayan aiki, tun daga masu fashewa zuwa na’urar Ultra Sonic masu wanki.Minghe ba kawai tana da kayan aiki na zamani ba amma kuma tana da kwararru ƙungiyar ƙwararrun injiniyoyi, masu aiki da sufetoci don tabbatar da ƙirar abokin ciniki ta zama gaskiya.

Manufactureran kwangilar masana'antar mutu. Abubuwan haɓakawa sun haɗa da sassan sanyi na sassan mutuɗar aluminum daga 0.15 lbs. zuwa 6 lbs., saurin canje-canje da aka saita, da aikin inji. Sabis-ƙarin ayyuka sun haɗa da gogewa, faɗakarwa, lalatawa, fashewar harbi, zane, zane, rufi, haɗuwa, da kayan aiki. Abubuwan da aka yi aiki tare sun haɗa da allo irin su 360, 380, 383, da 413.

Zinc ya mutu don jefa ƙirar ƙira / sabis na injiniya tare. Custom manufacturer na daidaici tutiya mutu simintin gyaran kafa. Castananan 'yan simintin gyare-gyare, pressurean ƙwanƙwasa masu juzu'in juzu'in simintin gyare-gyaren juzu'ai, ƙera simintin gyare-gyare na al'ada, ɓangaren mutu da' yan wasa masu mutuwa masu zaman kansu da ƙofar da aka hatimce za a iya ƙera su. Za'a iya kerarrar 'yan simintin a tsayi da faɗi har zuwa 24 a ciki. A cikin +/- 0.0005 a cikin. Haƙuri.

ISO 9001: 2015 bokan masana'anta ta mutu magnesium, Abubuwan haɓaka sun haɗa da matsin lamba na magnesium mai matsi mai yawa har zuwa tan 200 mai ɗumi mai zafi & 3000 ton mai sanyi, ƙirar kayan aiki, gogewa, gyare-gyaren, inji, foda & zanen ruwa, cikakken QA tare da damar CMM , taro, marufi & isarwa.

ITAF16949 bokan. Servicearin Sabis ɗin Gyare Hadawa zuba jari,yashi,Kushin nauyi, Stauren ɓoye ɓoye,Siffar Centrifugal,Cast Vacuum,Dindindin Mould Gyare, .Hanyoyin iyawa sun hada da EDI, taimakon injiniya, ingantaccen samfuri da aiki na sakandare.

Fitar Masana'antu Abubuwan Nazarin sassa don: Motoci, Bikes, Jirgin sama, kayan kiɗa, Jirgin ruwa, Na'urorin hangen nesa, na'urori masu auna sigina, na'urori masu auna sigina, Na'urori, Kayan lantarki, ,unshi, Clocks, Inji, Injiniya, Kayan Kaya, Kayan Jiki, Jigs, Telecom, Haske, Kayan aikin likita, Na'urar daukar hoto, Robobi, Sassaka, kayan sauti, kayan wasanni, Kayan aiki, Kayan wasa da ƙari.

Me Zamu taimake ku yi gaba?

Je zuwa Shafin Farko Don Mutu Wasa China

→Sassan Kasuwanci-Gano abin da muka aikata.

→ Tallan kwankwasiyya Game da Ayyukan Gyare Mutuwa

By Minghe Mutu Wasa Wasa | Categories: Labarai masu Taimakawa |Material Tags: Gyare Aluminum, Zinc Gyare, Fitar Magnesium, Castan Wasanni, Bakin Karfe Cast, Fitar tagulla,Gyare Tagulla,Fitar Bidiyo,Tarihin Kamfanin,Aluminum Mutu Gyare | Comments Off