Hanyoyi Da Matakai Na Stamping Mutu Zane

Akwai nau'ikan molds da yawa, waɗanda za a iya raba su zuwa:

- Molds na ƙarfe dangane da sarrafa maƙasudi da dabarun sarrafawa.

- Sarrafa ƙirar ƙarfe da ƙarfe.

A yau, editan yana magana game da hanya da aiwatar da stamping die design.

Analysis na stamping tsari na stamping sassa

Sassan hatimin dole ne su sami ingantacciyar fasahar buga tambari don samar da ingantattun sassan hatimin cikin mafi sauƙi kuma mafi tattalin arziƙi. Ana iya kammala nazarin aiwatar da sassan stamping bisa ga hanyoyin masu zuwa:

- Karanta zane zane. Bugu da ƙari da siffa da girman sassan, yana da mahimmanci a fahimci buƙatun daidaiton sassan da kaurin farfajiyar.

- Yi nazari ko tsari da sifar sassan sun dace da sarrafa tambura.

- Yi nazarin ko zaɓin tunani da alamar sikelin sassan daidai ne, kuma ko sikelin, daidaituwa da daidaiton siffa sun dace da sarrafa tambarin.

- Ko buƙatun kaurin farfajiyar sashi na ɓangaren ɓoyayyun sun yi yawa.

- Ko akwai babban isasshen tsari na samarwa.

Idan ƙirar ƙimar ta yi ƙanƙanta sosai, ya kamata ku yi shawarwari tare da mai tsarawa kuma ku ba da shawarar shirin sake fasalin shirin. Idan rukunin samarwa ya yi ƙanƙanta, ya kamata a yi la’akari da sauran hanyoyin samarwa don sarrafawa.

Tsarin Tsarin Tsari da Tsararren Tsarin Tsari

- Dangane da siffa da sikelin sassan hatimin, fara tantance yanayin tsarin buga tambarin, kamar: bugawa, zigzag, zane mai zurfi, buguwa, sakewa da sauran dabaru da dabarun tsara mutuwa. Hanyoyi da dabarun shiryawa na mutuwa.

- Yi lissafin matakin ɓarna na kowace hanyar yin hatimi. Idan matakin nakasa ya wuce iyakar nakasa, yakamata a kirga adadin naushi a cikin wannan tsari.

- Dangane da naƙasassun halaye da buƙatun inganci na kowane tsari, shirya madaidaicin jerin tambura. Yakamata a kula don tabbatar da cewa yankin nakasa a kowane tsari yanki ne mai rauni. Sashin da aka riga aka kafa (gami da ramin rami ko siffa) ba zai shiga cikin nakasa ba a cikin tsari mai zuwa. Sigin polygonal zigzag dole ne a lanƙwasa da farko a waje sannan a lanƙwasa Ciki, ya zama dole a tsara mahimman matakai da matakai masu mahimmanci kamar ƙira, daidaitawa, da jiyya mai zafi.

- Dangane da tabbatar da daidaiton sassan, ƙayyade hanyar haɗin tsari mai dacewa gwargwadon ƙimar samarwa da madaidaicin matsayi da buƙatun fitarwa.

- Don tsara tsare -tsaren tsari guda biyu ko fiye, da kwatanta ƙima, farashi, ƙimar samarwa, kaifi da gyarawa, rayuwa mai ƙyalli da amincin aiki, da sauransu, don zaɓar mafi kyawun tsarin aiwatarwa.

- Fara don ƙayyade kayan hatimi na kowane tsari.

Shirye -shiryen blank da ƙirar shimfidar ɓangarori

- Dangane da yanayin sassan hatimin, ƙididdige girman abubuwan da ba komai kuma yi zane -zane

- Dangane da yanayi da sikelin da babu komai, shirya zane -zane da lissafin ƙimar amfani da bayanai. Don tsara tsare -tsaren shimfida iri -iri, zaɓi mafi kyawun shirin tsakanin su ta hanyar kwatanci.

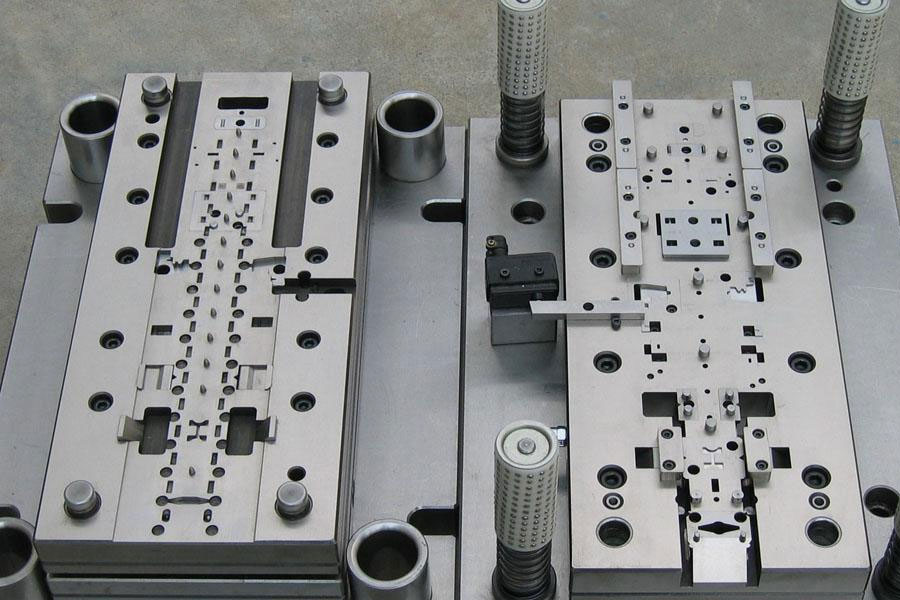

Stamping mutu zane

1. Ƙayyade hanyar ƙirar ƙirar kowane tsari na sarrafa stamping, da kuma yin ƙirar ƙirar ƙirar.

2. Yi takamaiman tsarin tsari don ƙayyadaddun tsari na 1-2, da yin zane-zanen aiki.

Hanyar shiryawa kamar haka:

- Ƙayyade nau'in ƙirar: shin ƙyalli ne mai sauƙi, ci gaba mai ƙyalli ko sifa mai haɗawa.

- Shirya sassan sassa na aiki: ƙididdige girman maɗaukaki da raƙuman ruwa mai mutuwa da tsayin madaidaiciya da ƙirar ƙira, ƙayyade tsarin ƙwanƙwasa da ƙirar ƙira da hanyoyin haɗi da gyarawa.

- Ƙayyade wuri da hanyar nisan zango, kuma shirya madaidaicin matsayi da sassan nesa.

- Ƙayyade hanyoyin latsawa, zazzagewa, fitarwa da tura sassan, da kuma tsara faranti masu riƙe daidai, sauke faranti, da tura tubalan.

- Tsarin tushe mai ƙarfi: gami da tsara manyan tushe da ƙananan tushe da hanyoyin jagora, kuma ana iya zaɓar madaidaitan kwandon shara.

- Dangane da kammala ayyukan da ke sama, ana yin ƙirar ƙirar gwargwadon gwargwado. Da farko yi amfani da layi mai ɗigo biyu don yin fanko, sannan kuma sanya sassan aiki, sannan sanya sassan matsayi da na nesa, yi amfani da ɓangarorin haɗin don haɗa sassan da ke sama, daga ƙarshe kuma a sanya sassan latsawa da saukewa a matsayin da ya dace. Dangane da takamaiman yanayin ƙirar, ana iya daidaita jerin abubuwan da ke sama daidai.

- Zane na aiki yakamata ya nuna girman girman kwandon na ƙirar, tsayin ƙulli na ƙirar, sikelin haɗin gwiwa, da kuma hanyar haɗin gwiwa nau'in buga tambarin ƙira da aiwatar da tsarin ƙirar. Taswirar aikin yakamata ya nuna buƙatun daidaitaccen samar da injin da yanayin fasaha. Yakamata a yi taswirar aiki daidai da ƙa'idodin zane na ƙasa, tare da madaidaicin taken taken da cikakken jerin sunaye. Idan ya mutu, yi zane zane a kusurwar hagu na aikin.

- Yi lissafin cibiyar matsa lamba na ƙirar kuma bincika ko cibiyar matsa lamba da layin madaidaiciyar madaidaiciyar madaidaicin ta dace. Idan ba su zo daidai ba, yi gyare -gyaren da suka dace da sakamakon ƙirar.

- Yi lissafin ƙarfin bugun, kuma a ƙarshe zaɓi kayan aikin hatimin, kuma duba matakan dacewa na kayan mutu da tambarin (rufaffiyar tsawo, farfajiyar aiki, mutuƙar girman kayan aikin, da sauransu).

Da fatan za a adana tushe da adireshin wannan labarin don sake bugawa: Hanyoyi Da Matakai Na Stamping Mutu Zane

Minghe Kamfanin 'Yan Wasa Masu Mutu aka sadaukar domin tsirar da samar da inganci da kuma high yi Gyare sassa (karfe mutu simintin sassa Range yafi hada da Thin-Wall Mutu Wasa,Hot Chamber Mutu Wasa,Cold Chamber Mutu Wasa), Zagaye Sabis (Mutuwar 'Yan Wasa,CNC machining,Motsa Motsa, Jiyya na sama) .Adadin al'ada Aluminium ya mutu, magnesium ko Zamak / zinc mutu simintin gyare-gyare da sauran buƙatun simintin maraba don tuntube mu.

Karkashin kulawar ISO9001 da TS 16949, Ana aiwatar da dukkan matakai ta hanyar daruruwan injunan jefa simintin da suka mutu, injunan axis 5, da sauran kayan aiki, tun daga masu fashewa zuwa na’urar Ultra Sonic masu wanki.Minghe ba kawai tana da kayan aiki na zamani ba amma kuma tana da kwararru ƙungiyar ƙwararrun injiniyoyi, masu aiki da sufetoci don tabbatar da ƙirar abokin ciniki ta zama gaskiya.

Manufactureran kwangilar masana'antar mutu. Abubuwan haɓakawa sun haɗa da sassan sanyi na sassan mutuɗar aluminum daga 0.15 lbs. zuwa 6 lbs., saurin canje-canje da aka saita, da aikin inji. Sabis-ƙarin ayyuka sun haɗa da gogewa, faɗakarwa, lalatawa, fashewar harbi, zane, zane, rufi, haɗuwa, da kayan aiki. Abubuwan da aka yi aiki tare sun haɗa da allo irin su 360, 380, 383, da 413.

Zinc ya mutu don jefa ƙirar ƙira / sabis na injiniya tare. Custom manufacturer na daidaici tutiya mutu simintin gyaran kafa. Castananan 'yan simintin gyare-gyare, pressurean ƙwanƙwasa masu juzu'in juzu'in simintin gyare-gyaren juzu'ai, ƙera simintin gyare-gyare na al'ada, ɓangaren mutu da' yan wasa masu mutuwa masu zaman kansu da ƙofar da aka hatimce za a iya ƙera su. Za'a iya kerarrar 'yan simintin a tsayi da faɗi har zuwa 24 a ciki. A cikin +/- 0.0005 a cikin. Haƙuri.

ISO 9001: 2015 bokan masana'anta ta mutu magnesium, Abubuwan haɓaka sun haɗa da matsin lamba na magnesium mai matsi mai yawa har zuwa tan 200 mai ɗumi mai zafi & 3000 ton mai sanyi, ƙirar kayan aiki, gogewa, gyare-gyaren, inji, foda & zanen ruwa, cikakken QA tare da damar CMM , taro, marufi & isarwa.

ITAF16949 bokan. Servicearin Sabis ɗin Gyare Hadawa zuba jari,yashi,Kushin nauyi, Stauren ɓoye ɓoye,Siffar Centrifugal,Cast Vacuum,Dindindin Mould Gyare, .Hanyoyin iyawa sun hada da EDI, taimakon injiniya, ingantaccen samfuri da aiki na sakandare.

Fitar Masana'antu Abubuwan Nazarin sassa don: Motoci, Bikes, Jirgin sama, kayan kiɗa, Jirgin ruwa, Na'urorin hangen nesa, na'urori masu auna sigina, na'urori masu auna sigina, Na'urori, Kayan lantarki, ,unshi, Clocks, Inji, Injiniya, Kayan Kaya, Kayan Jiki, Jigs, Telecom, Haske, Kayan aikin likita, Na'urar daukar hoto, Robobi, Sassaka, kayan sauti, kayan wasanni, Kayan aiki, Kayan wasa da ƙari.

Me Zamu taimake ku yi gaba?

Je zuwa Shafin Farko Don Mutu Wasa China

→Sassan Kasuwanci-Gano abin da muka aikata.

→ Tallan kwankwasiyya Game da Ayyukan Gyare Mutuwa

By Minghe Mutu Wasa Wasa | Categories: Labarai masu Taimakawa |Material Tags: Gyare Aluminum, Zinc Gyare, Fitar Magnesium, Castan Wasanni, Bakin Karfe Cast, Fitar tagulla,Gyare Tagulla,Fitar Bidiyo,Tarihin Kamfanin,Aluminum Mutu Gyare | Comments Off