Tasirin Fim ɗin Karfe na Ƙarfe akan Ingancin Fitar Aluminum Alloy Castings

"Casting" wani tsari ne na sarrafa ƙarfe. Sanannen abu ne cewa ƙarfe mai ruwa a babban zafin jiki za a yi oxide a samansa a cikin iska kuma ya samar da fim ɗin oxide.

Koyaya, na dogon lokaci, tasirin wannan fim ɗin oxide akan ingancin simintin ƙarfe na aluminium kawai yayi la'akari da matsalar abubuwan da ba na ƙarfe ba a cikin narkakken ƙarfe, kuma ba a ƙara yin tattaunawa ba.

J. Campbell na Jami'ar Birmingham, Burtaniya, dangane da shekaru na bincike, ya gano cewa fina-finan da aka nade suna da tasiri ƙwarai a kan ingancin siminti na aluminium daga bangarorin macro da ƙananan abubuwa. Campbell et al. yi imani cewa fahimtar bi-fina-finai shine mafi kyawun binciken. A halin yanzu, muna komawa zuwa ga ƙarshe na ƙarshe da fahimtar da Campbell da wasu suka samu a matsayin "ka'idar bi-films".

Bayan interlayer na oxide film da hannu a cikin ruwa aluminum gami, da tasiri a kan ingancin da simintin gyare -gyare za a iya raba kashi biyu:

Oneaya shine ɓangaren macroscopic. Baya ga yanke matrix na ƙarfe don rage kaddarorin injin, yana kuma haifar da lahani na simintin kamar porosity da ƙaramin raguwa;

Isayan shine ɓangaren microscopic, wanda ke da tasiri mai mahimmanci akan ƙimar hatsi, tazara tsakanin dendrites, da tasirin gyaran Na da Sr a cikin aluminium-silicon gami.

1. Halayen fim ɗin oxide a saman ƙarfe mai ruwa

Yin nazarin halayen fim ɗin oxide, yawa da narkar da ruwan mahaifa na ƙarfe wanda aka haɗe shi ba za a iya la'akari da shi a lokaci guda ba. Dangane da ƙarfe da ƙarfe, ɗauki misalin ƙera ƙarfe a matsayin misali. FeO da aka samar ta hanyar oxyidation na narkakken ƙarfe yana da wurin narkewa da yawa da yawa fiye da na narkakken ƙarfe, kuma yana aiki sosai a yanayin zafi, kuma a zahiri ba zai yiwu ya wanzu shi kaɗai ba. FeO na iya haɗuwa tare da SiO2 don samar da ƙarancin narkewa FeO.SiO2, wanda zai iya amsawa tare da silicon da manganese a cikin ƙarfe don ƙirƙirar MnO da SiO2 sannan a haɗa don ƙirƙirar MnO.SiO2. Hakanan yana iya amsawa tare da carbon a cikin ƙarfe don samar da CO, kuma za a sami ƙaramin sashi. Narkar da shi a narkakken karfe. Idan maganin deoxidation bai dace ba, ko kuma narkakken ƙarfe yana yin oxidation sau biyu bayan taɓawa, zai ƙara adadin abubuwan da ba na ƙarfe ba a cikin ƙarfe, ko haifar da lahani kamar ramuka ko haɗa slag a saman simintin. Koyaya, oxides da aka samar akan farfajiyar ƙarfe mai narkewa suna da wuraren narkewa ƙasa da zafin zafin baƙin ƙarfe kuma yana iya tarawa kawai. Ba za a iya nade su a cikin fim ɗin oxide ba kuma a dakatar da su a cikin narkakken ƙarfe, don haka ba za a sami matsaloli da abin da ke haɗa fim ɗin oxide ba. .

Halin allurar aluminium da allurar magnesium gaba ɗaya sun bambanta. Taƙaitaccen bayanin ƙirar aluminium shine kamar haka: Aluminium yana aiki sosai a cikin yanayin ruwa, kuma saman narkakken aluminium yana iya sauƙaƙe amsa tare da iskar oxygen a cikin sararin samaniya don samar da finafinan Al2O3. Maɓallin narkewa na Al2O3 ya fi na allurar aluminium ɗin ruwa, kuma yana da tsayayye sosai. Nauyin Al2O3 yana da ɗan girma fiye da na narkakkiyar aluminium. Sabili da haka, fim ɗin Al2O3 yana da sauƙin dakatarwa a cikin ruwan aluminium kuma ba zai tara kuma ya ware daga ruwan aluminium ba. Lokacin da aka murƙushe ruwan gami na aluminium, fim ɗin Al2O3 a farfajiya zai nade cikin sandwich kuma a jawo shi cikin narkakken ƙarfe, yana haifar da matsaloli na musamman na allurar aluminium.

2. Samuwar interlayer film oxide da illolin sa

Ruwan allurar aluminium zai kasance da damuwa sosai yayin aikin narkewa, lokacin da yake fitowa daga murhun narkewa, a lokacin jiyya na metamorphic, lokacin fesawa da tsarkakewa a cikin saurin iska, da kuma lokacin zubar. Rikicin farfajiyar ƙarfe na ruwa zai ja fim ɗin oxide a saman sa, ya sa ya faɗaɗa, ninka, da karyewa. Rufin ruwa mai tsafta wanda aka fallasa a cire haɗin fim ɗin oxide za a yi oxide don samar da sabon fim ɗin oxide. Nade fim ɗin oxide zai sa busasshen saman da ke gefen da ke fuskantar yanayi ya manne da juna, kuma za a nade ƙaramin iska a tsakanin busasshen saman biyu don zama “sandwich oxide film”. Mai haɗa fim ɗin oxide yana da sauƙin shiga cikin narkakken ƙarfe, kuma za a matse shi cikin ƙananan dunƙule a ƙarƙashin aikin ƙarfen da aka narkar da shi.

Saboda wurin narkewa na Al2O3 ya fi digiri Celsius sama da dubu ɗaya sama da zafin ruwan allurar aluminium, kuma yana da babban yanayin kwanciyar hankali na sinadarai, ƙananan gungu ba za su juye ba kuma ba za su narke a cikin allurar aluminium ba. Kodayake ƙimar Al2O3 ta ɗan fi girma fiye da na ruwan gami na aluminium, yawaitar fim ɗin oxide wanda aka nannade cikin iska yana da kusanci da na ruwan gami na aluminum. Sabili da haka, ban da yuwuwar nutsewar fim ɗin oxide a yayin tsayin dogon lokaci a cikin babban tanderun da aka riƙe, za a dakatar da shi sosai a cikin ruwan gami na aluminium a ƙarƙashin yanayin samarwa. Ruwan allurar aluminium wanda ya dakatar da masu haɗa fim ɗin oxide zai samar da ƙarin masu haɗa fim ɗin oxide lokacin da aka sake damuwa. A lokacin samar da simintin gyare -gyare, ƙamshin allura, zubowa daga tanderu, gyaran gyare -gyare, maganin tsarkakewa, zubarwa da sauran ayyuka za su haifar da tashin hankali mai ƙarfi a cikin ruwan gami na aluminium. Bugu da ƙari don riƙe mai haɗa fim ɗin oxide na asali, ruwan gami na aluminium shima zai haifar da An sake damuwa kuma ana ci gaba da ƙara sabbin masu haɗa fim ɗin oxide. Saboda haka, narkakken ƙarfe da ke shiga cikin ramin yana ƙunshe da adadi mai yawa na masu haɗa fim ɗin oxide. Bayan narkakken ƙarfe ya cika ramin, yana cikin yanayi na tsaye, kuma mai haɗa fim ɗin oxide da aka matse a cikin gungu zai sannu a hankali zuwa ƙaramin yanki. Bayan an narkar da ƙarfen ƙarfe a ƙarƙashin layin ruwa, ɓarna da haɓaka dendrites suma sune abubuwan da ke haɓaka shimfidar fim ɗin oxide wanda aka matse cikin agglomerates.

Bayan an tabbatar da simintin gyare -gyare, babban adadi na ƙananan masu haɗa fim ɗin oxide flaky su kansu ƙananan fasa ne, waɗanda ke taka rawar yanke matrix na ƙarfe. Tabbas, za a rage kaddarorin inji na gami, amma mafi cutarwa shine shigar ramuka da ƙananan ramuka. Yayin da zafin zafin ƙarfe na ruwa a hankali yake raguwa, narkewar sinadarin hydrogen a cikin narkakken ƙarfe na ci gaba da raguwa, amma yana da matuƙar wahala ga hydrogen ya yi ƙaura daga ƙarfe mai ruwa a cikin sifar pores. Lokacin da aka samar da wani sabon lokaci (lokacin gas) a cikin yanayin ruwa mai kama da juna, koyaushe ana samun shi ta hanyar tara wasu ƙwayoyin halitta ko ƙwayoyin farko, kuma ƙarar sa ƙarama ce. Wannan ƙaramin sabon lokaci yana da babban yanki na musamman (wato, farfajiya ta kowace ƙarar raka'a). Don samar da sabon dubawa, ana buƙatar yin aiki akan sa. Wannan shine kuzarin kuzari na sabon lokaci, wato yanki da farfajiyarsa. Samfurin. Kusan ba zai yiwu ba a sami irin wannan babban adadin kuzari yayin aiwatar da sanyaya ruwan allurar gami na aluminium. Ko da an samar da ainihin sabon sashi, yana buƙatar kuzari mai yawa don girma, kuma yana yiwuwa a girma ne kawai lokacin da girman sabon matakin ya wuce wani ƙima mai mahimmanci. Jigon sabon lokaci tare da girman da ya yi ƙasa da ƙima mai mahimmanci ba zai iya girma ba kuma zai ɓace ne da kansa. A ka'idar, yana da matukar wahala lokacin iskar gas ya zama tsakiya kuma ya girma a cikin ruwa. A gaskiya. Idan babu wasu abubuwan da ke haifar da su, a ƙarƙashin yanayin cewa abun cikin hydrogen ɗin na al'ada ne, ba zai yiwu a samar da ramuka a cikin aluminium mai kama da juna ba saboda hazo na hydrogen.

Lokacin da narkakken ƙarfe ya ƙunshi babban adadin masu dakatar da fim ɗin oxide, yanayin ya sha bamban. Yawancin rufin fim ɗin oxide an rufe shi da ƙaramin iska. Lokacin da zafin zafin baƙin ƙarfe ya ragu kuma solubility na hydrogen da ke cikinsa ya ragu, ƙananan kumfa na iska a cikin interlayer fim na oxide ba su da fa'ida ga hydrogen, kuma hydrogen ɗin da ke narkar da baƙin ƙarfe zai motsa zuwa kumburin iska. Watsawa matsakaici yana da dacewa sosai. Hydrogen yana watsawa zuwa cikin ƙananan kumfa na iska, wanda ke faɗaɗa interlayer fim na oxide, kuma yana haifar da ramuka a cikin simintin gyare -gyare. Idan maganin tsarkakewa na ruwan gami na aluminium yana da kyau kuma abun cikin hydrogen a cikin narkakken ƙarfe yana da ƙarancin ƙima, za a sami ramuka kaɗan a cikin simintin gyaran. Koyaya, idan babu mai haɗa fim ɗin oxide a cikin narkakken ƙarfe, koda kuwa abun da ke cikin hydrogen a cikin narkakken ƙarfe yana da girma, ana iya narkar da sinadarin hydrogen ɗin a cikin gami a cikin yanayin da ya fi ƙarfin lokacin ƙarfi, kuma ba zai yiwu a samar da ramuka ba. Idan yanayin ciyar da simintin gyare -gyare ba shi da kyau, ramukan ƙanƙara za su faru yayin aiwatarwa da raguwa. Tun da abin da ke cikin fim ɗin oxide ba shi da fa'ida, yana da sauƙin cirewa, kuma ramukan ramuka galibi ana yin su ne a tsakiyar fim ɗin oxide. A wannan yanayin, sinadarin hydrogen da aka narkar da shi a cikin narkakken ƙarfe shima zai bazu cikinsa, wanda hakan zai sa pores ɗin su faɗaɗa.

A taƙaice, ana iya ɗauka cewa don simintin gyare -gyare na aluminium, interlayer fim ɗin oxide shine babban dalilin lalacewar kaddarorin injin na kayan da ramin rami da ramuka na simintin. Domin inganta kaddarorin kayan aikin da haɓaka ƙimar simintin, yana da mahimmanci a ɗauki matakan kawar da interlayer fim na oxide fiye da ƙarfafa aikin degassing da tsarkakewa.

Da fatan za a adana tushe da adireshin wannan labarin don sake bugawa: Tasirin Fim ɗin Karfe na Ƙarfe akan Ingancin Fitar Aluminum Alloy Castings

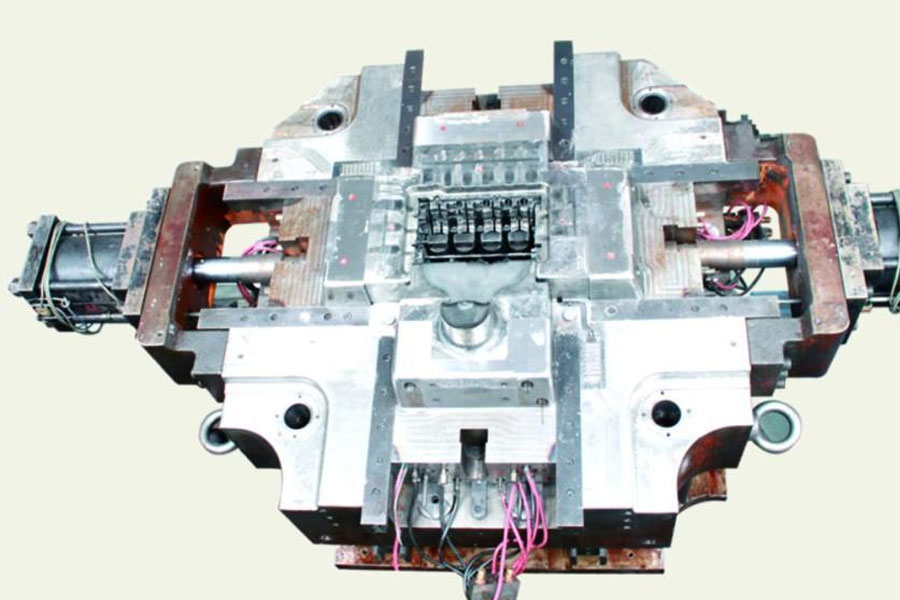

Minghe Kamfanin 'Yan Wasa Masu Mutu aka sadaukar domin tsirar da samar da inganci da kuma high yi Gyare sassa (karfe mutu simintin sassa Range yafi hada da Thin-Wall Mutu Wasa,Hot Chamber Mutu Wasa,Cold Chamber Mutu Wasa), Zagaye Sabis (Mutuwar 'Yan Wasa,CNC machining,Motsa Motsa, Jiyya na sama) .Adadin al'ada Aluminium ya mutu, magnesium ko Zamak / zinc mutu simintin gyare-gyare da sauran buƙatun simintin maraba don tuntube mu.

Karkashin kulawar ISO9001 da TS 16949, Ana aiwatar da dukkan matakai ta hanyar daruruwan injunan jefa simintin da suka mutu, injunan axis 5, da sauran kayan aiki, tun daga masu fashewa zuwa na’urar Ultra Sonic masu wanki.Minghe ba kawai tana da kayan aiki na zamani ba amma kuma tana da kwararru ƙungiyar ƙwararrun injiniyoyi, masu aiki da sufetoci don tabbatar da ƙirar abokin ciniki ta zama gaskiya.

Manufactureran kwangilar masana'antar mutu. Abubuwan haɓakawa sun haɗa da sassan sanyi na sassan mutuɗar aluminum daga 0.15 lbs. zuwa 6 lbs., saurin canje-canje da aka saita, da aikin inji. Sabis-ƙarin ayyuka sun haɗa da gogewa, faɗakarwa, lalatawa, fashewar harbi, zane, zane, rufi, haɗuwa, da kayan aiki. Abubuwan da aka yi aiki tare sun haɗa da allo irin su 360, 380, 383, da 413.

Zinc ya mutu don jefa ƙirar ƙira / sabis na injiniya tare. Custom manufacturer na daidaici tutiya mutu simintin gyaran kafa. Castananan 'yan simintin gyare-gyare, pressurean ƙwanƙwasa masu juzu'in juzu'in simintin gyare-gyaren juzu'ai, ƙera simintin gyare-gyare na al'ada, ɓangaren mutu da' yan wasa masu mutuwa masu zaman kansu da ƙofar da aka hatimce za a iya ƙera su. Za'a iya kerarrar 'yan simintin a tsayi da faɗi har zuwa 24 a ciki. A cikin +/- 0.0005 a cikin. Haƙuri.

ISO 9001: 2015 bokan masana'anta ta mutu magnesium, Abubuwan haɓaka sun haɗa da matsin lamba na magnesium mai matsi mai yawa har zuwa tan 200 mai ɗumi mai zafi & 3000 ton mai sanyi, ƙirar kayan aiki, gogewa, gyare-gyaren, inji, foda & zanen ruwa, cikakken QA tare da damar CMM , taro, marufi & isarwa.

ITAF16949 bokan. Servicearin Sabis ɗin Gyare Hadawa zuba jari,yashi,Kushin nauyi, Stauren ɓoye ɓoye,Siffar Centrifugal,Cast Vacuum,Dindindin Mould Gyare, .Hanyoyin iyawa sun hada da EDI, taimakon injiniya, ingantaccen samfuri da aiki na sakandare.

Fitar Masana'antu Abubuwan Nazarin sassa don: Motoci, Bikes, Jirgin sama, kayan kiɗa, Jirgin ruwa, Na'urorin hangen nesa, na'urori masu auna sigina, na'urori masu auna sigina, Na'urori, Kayan lantarki, ,unshi, Clocks, Inji, Injiniya, Kayan Kaya, Kayan Jiki, Jigs, Telecom, Haske, Kayan aikin likita, Na'urar daukar hoto, Robobi, Sassaka, kayan sauti, kayan wasanni, Kayan aiki, Kayan wasa da ƙari.

Me Zamu taimake ku yi gaba?

Je zuwa Shafin Farko Don Mutu Wasa China

→Sassan Kasuwanci-Gano abin da muka aikata.

→ Tallan kwankwasiyya Game da Ayyukan Gyare Mutuwa

By Minghe Mutu Wasa Wasa | Categories: Labarai masu Taimakawa |Material Tags: Gyare Aluminum, Zinc Gyare, Fitar Magnesium, Castan Wasanni, Bakin Karfe Cast, Fitar tagulla,Gyare Tagulla,Fitar Bidiyo,Tarihin Kamfanin,Aluminum Mutu Gyare | Comments Off